Air switch limiting bolt with heated bouncing function

A technology of limit bolt and air switch, used in thermal switch parts, fire rescue and other directions, can solve the problem of inability to extinguish fire with air switch, and achieve the effect of avoiding fire spread, excellent control response speed, and avoiding delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

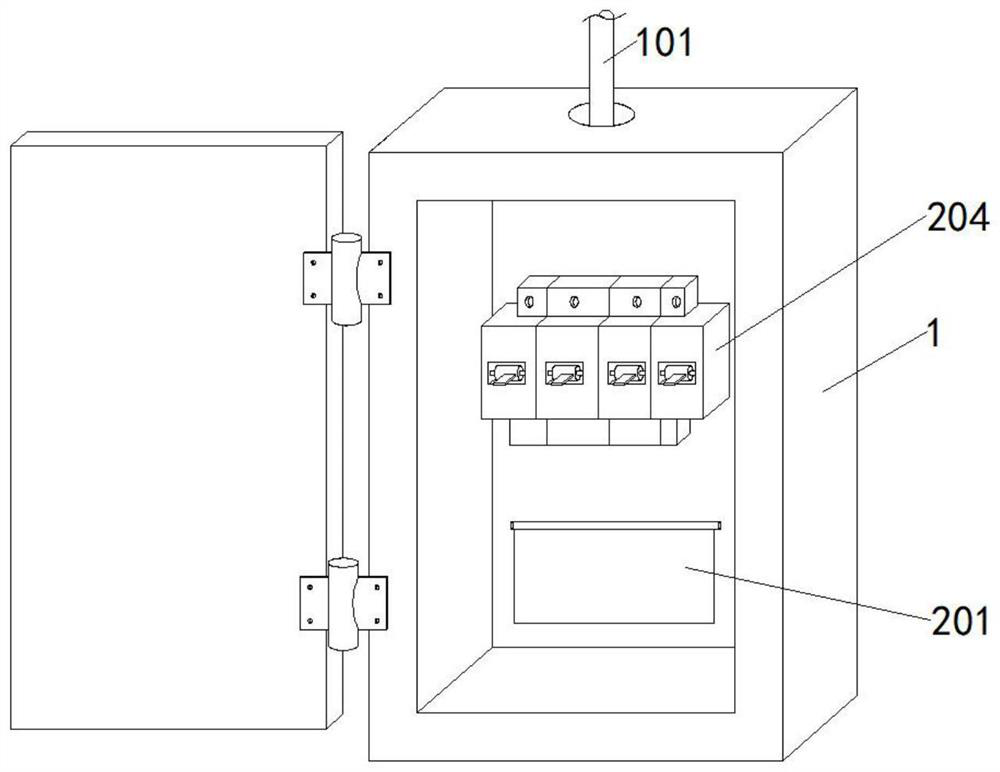

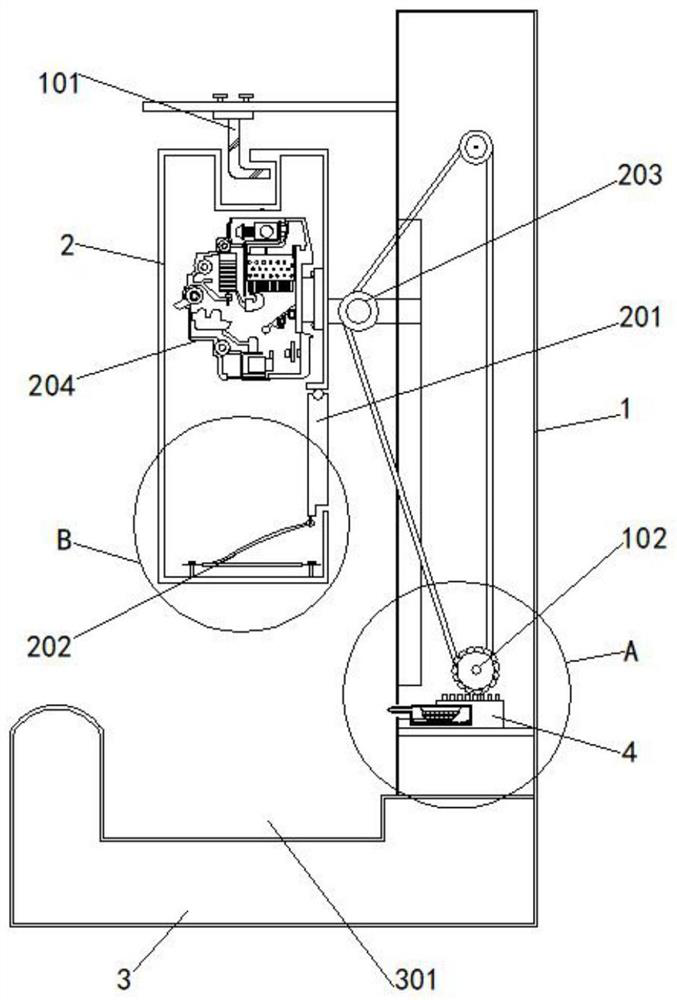

[0029] as attached figure 1 to attach Image 6 Shown:

[0030] The present invention provides a space-opening limit bolt with the function of popping up when heated, and the space-opening space-limiting bolt with the function of popping up when heated includes an installation and fixing block 1; inside the installation and fixing block 1, a fire extinguishing mechanism and a heat triggering mechanism are arranged;

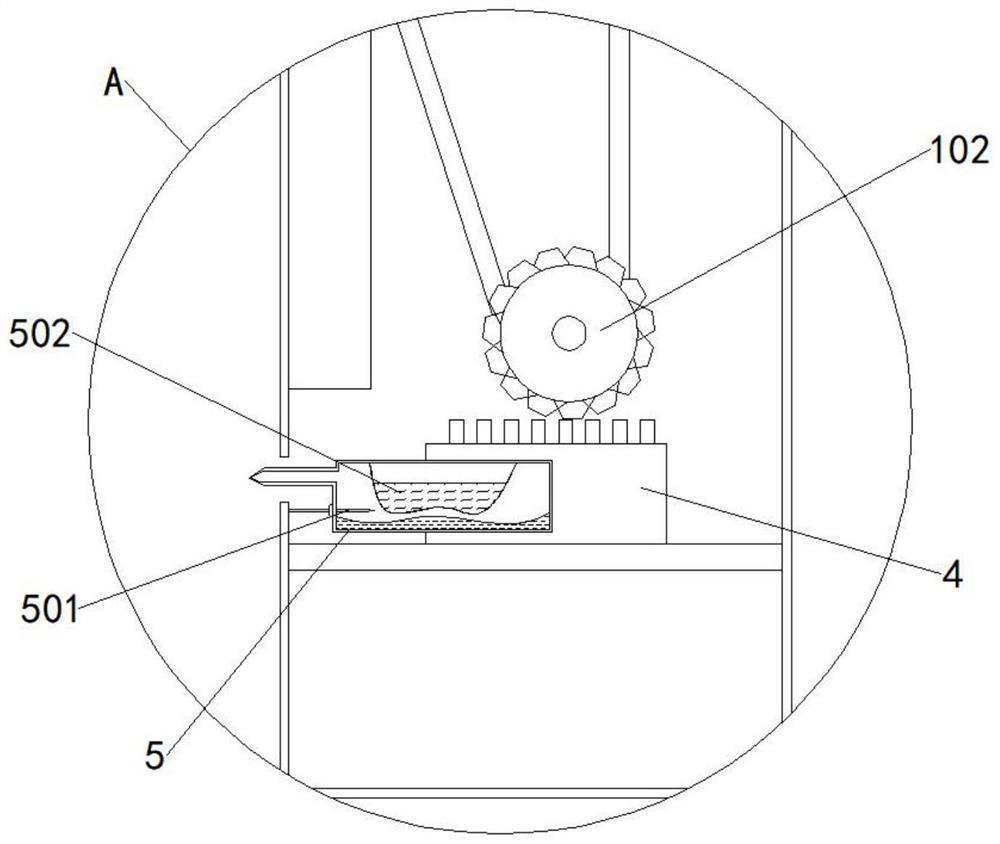

[0031] Wherein, the heat trigger mechanism includes: L shape memory alloy limit bolt 101, toothed steel wire wheel 102, electric meter box 2, steel wire wheel 203, air switch 204, base 3, base groove 301, toothed slider 4;

[0032] The top of the fixing block 1 is fixedly installed with an L shape memory alloy limit bolt 101, and the meter box 2 is slidably installed on one side of the installation fixing block 1, and the L shape memory alloy limit bolt 101 fixes the meter box 2 on the top of the fixing block 1 On one side of the fixed block 1, an air switch 204 ...

Embodiment 2

[0038] The present invention also includes a heat opening mechanism, which includes a flip cover 201 and a butterfly bimetal 202;

[0039] A flip cover 201 is installed on one side of the bottom of the meter box 2, and a butterfly bimetal sheet 202 is fixedly installed on the bottom side of the meter box 2, and the butterfly bimetal sheet is movably connected to the flip cover 201. After the inside of the meter box 2 catches fire, the butterfly bimetal sheet will Sheet 202 encounters thermal deformation and drives flip cover 201 to turn up and one side of electric meter box 2 is opened to facilitate fire extinguishing.

[0040] The specific usage and function of this embodiment:

[0041]In the present invention, firstly, after the electric meter box 2 is affected by the surrounding environment and catches fire, in order to protect the air switch 204 from being damaged, the L shape memory alloy stopper 101 will become straight when heated, and the electric meter box 2 will no l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com