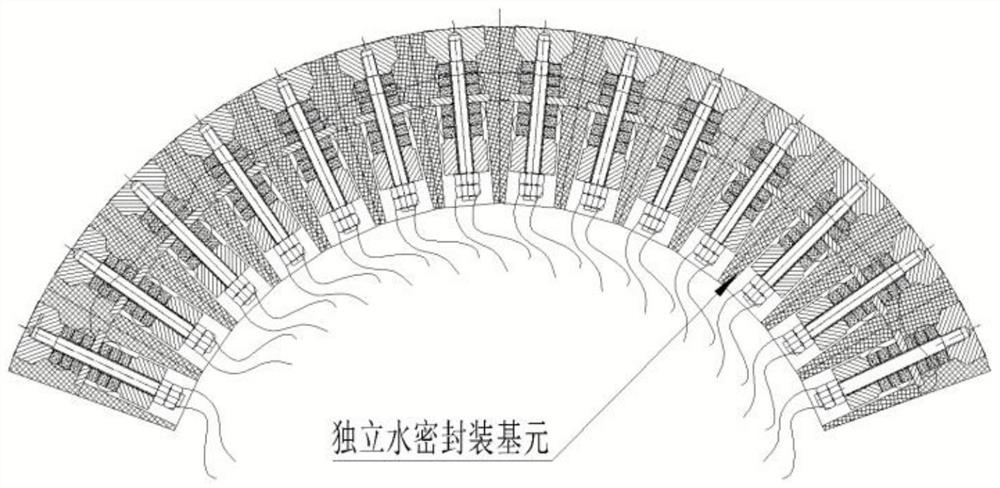

Manufacturing method of large-size arc-shaped 1-3 type piezoelectric composite material

A technology of piezoelectric composite materials and manufacturing methods, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., and can solve the difficulty of mold splicing to meet the installation accuracy And the reliability of electrodes, the inability to produce large sizes, etc., to achieve the effect of reducing process difficulty and production costs, and improving reliability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

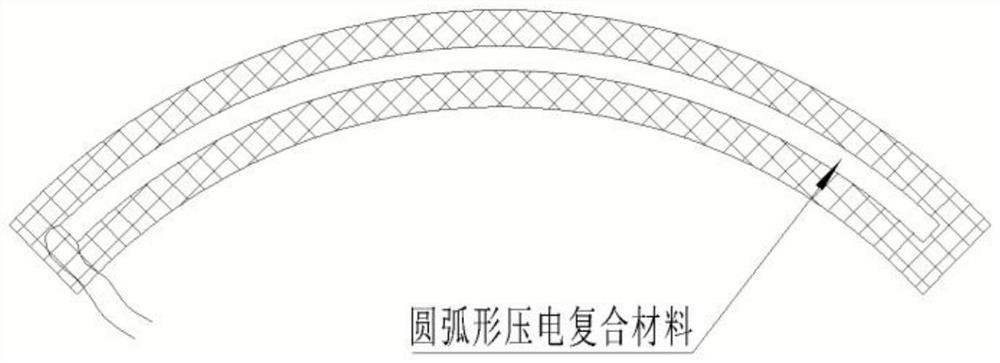

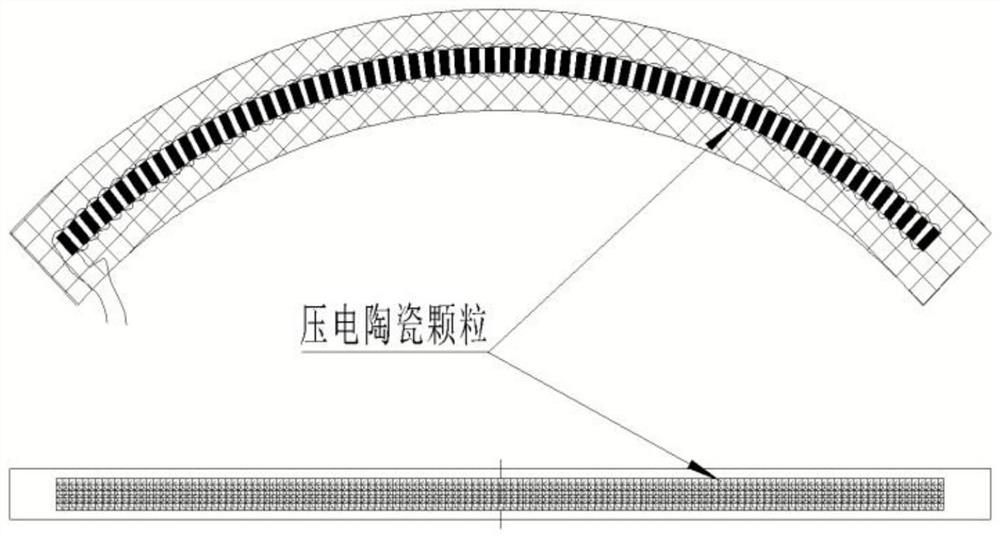

[0036] Such as Figure 4 As shown, this embodiment provides a large-scale arc-shaped 1-3 type piezoelectric composite material manufacturing method, in order to meet the needs of large-scale arc-shaped medium and high-frequency underwater acoustic emission arrays, by gluing planar piezoelectric ceramics on a flexible plane Cutting on the bottom plate—casting—recutting—plane splicing—bending into an arc—casting method, including the following steps:

[0037] Step S1: Bond the bottom surface of the planar piezoelectric ceramic 1 to the first layer of flexible bottom plate 2 with an adhesive or double-sided tape. The width dimension is divided into several splicing and cutting machine strokes according to the final large-size arc division. The flexible bottom plate 2 can be bent into a circular arc and can be cut. The adhesive and double-sided tape can be torn off or at a specific temperature Solvent and other conditions to remove;

[0038] Specifically, in the embodiment, the ...

Embodiment 2

[0052] Such as Figure 5 As shown, this embodiment also provides a method for manufacturing a large-size arc-shaped 2-2 piezoelectric composite material, which specifically includes the following steps:

[0053] Step S1: Bond the bottom surface of the planar piezoelectric ceramic 1 on the first layer of flexible bottom plate 2 with an adhesive or double-sided tape. The thickness of the planar piezoelectric ceramic 1 is determined according to the frequency of the 2-2 composite material, and the length The width dimension is divided into several splicing and cutting machine strokes according to the final large-size arc division. The flexible bottom plate 2 can be bent into a circular arc and can be cut. The adhesive and double-sided tape can be torn off or at a specific temperature Solvent and other conditions to remove;

[0054] Step S2: cutting the above-mentioned planar piezoelectric ceramic 1 along the second direction II to obtain a planar piezoelectric ceramic block comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length dimension | aaaaa | aaaaa |

| Width size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com