Automatic backwashing centrifugation-sandstone integrated filter

A sand and gravel filter, centrifugal filter technology, applied in the direction of fixed filter element filter, filtration separation, filtration loop, etc., can solve the problem of failure to achieve separation efficiency and effective filtration particle size synergistic improvement, failure to achieve sand and gravel filter Heterogeneous filter material backwashing and other problems to achieve the effect of ensuring separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

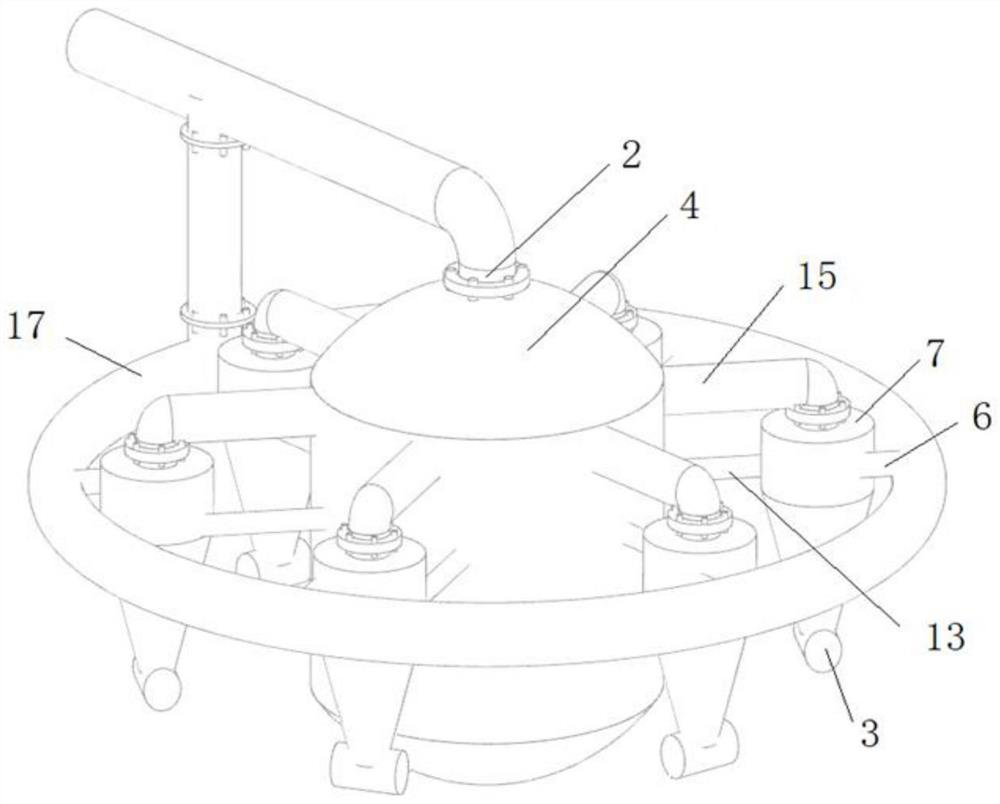

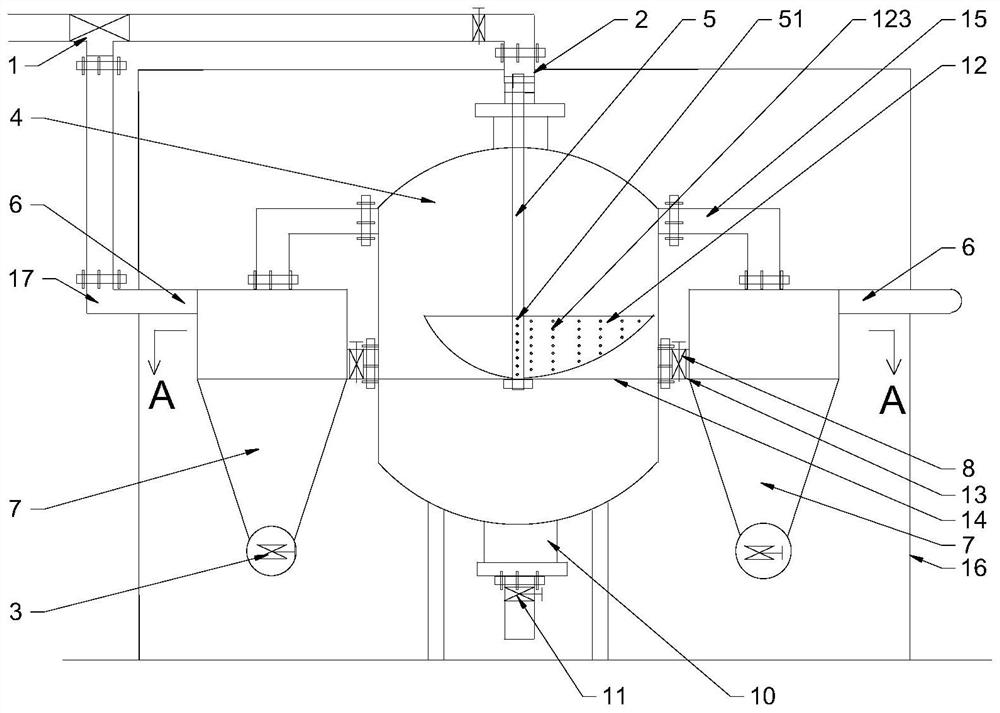

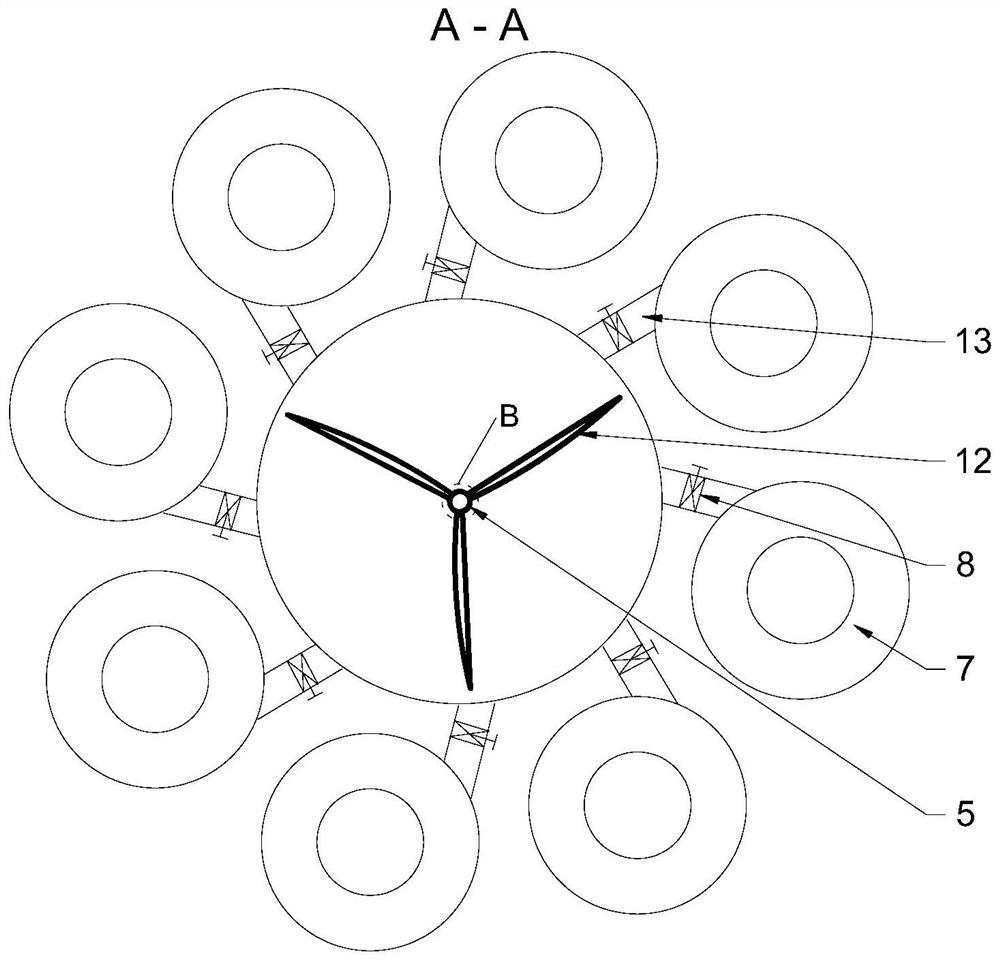

[0030] Such as figure 1 The shown embodiment of the present invention includes: water inlet three-way solenoid valve 1, sand filter inlet pipe 2, sand collection tank sand discharge solenoid valve 3, sand filter 4, centrifugal filter inlet pipe 6, centrifugal filter device 7, filter material outlet solenoid valve 8, drainage hole 9, sandstone filter drain pipe 10, sandstone filter water purification outlet valve 11, sand discharge pipe 13 and sand delivery pipe 15, wherein sandstone filter 4 is arranged on In the center, several centrifugal filters 7 equal in distance to the gravel filter 4 on the same horizontal plane are arranged on the outside of the gravel filter 4, and the centrifugal filters 7 are evenly arranged along the circumference of the gravel filter 4; The outlet at the top of the 7 is connected to the top of the sand filter 4 tank body through...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap