Carbonated beverage processing and blending device

A carbonated beverage and blending technology, applied in transportation and packaging, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve the problems of low mixing efficiency, slow speed, uneven mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

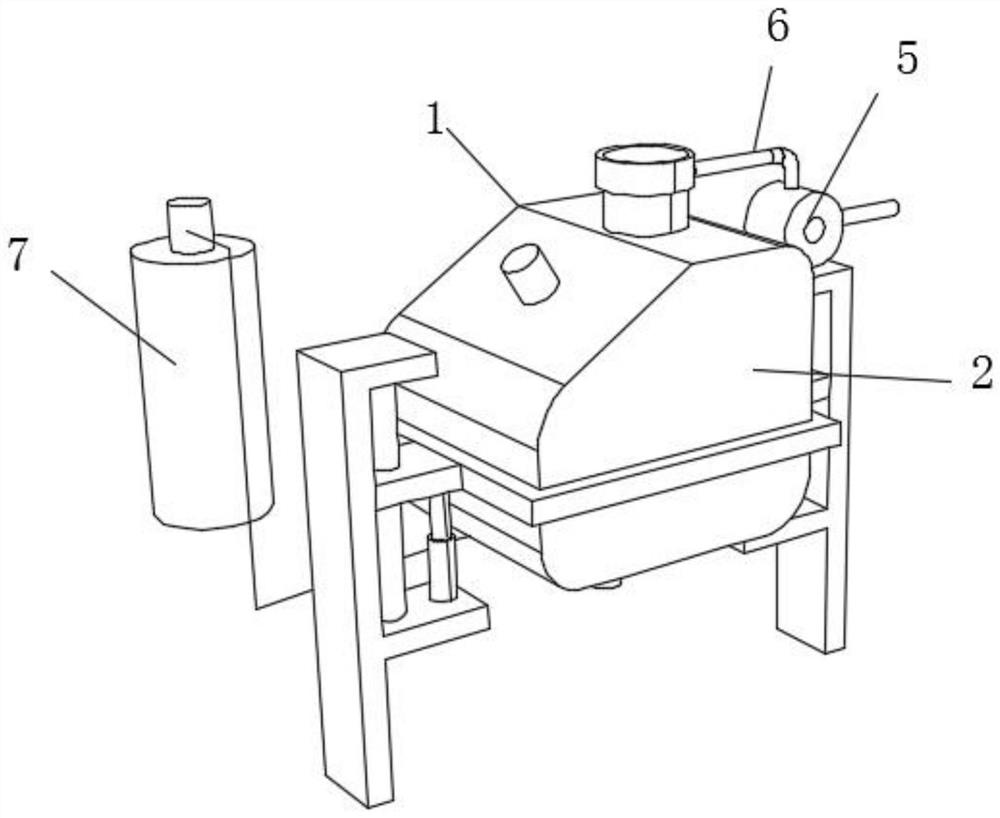

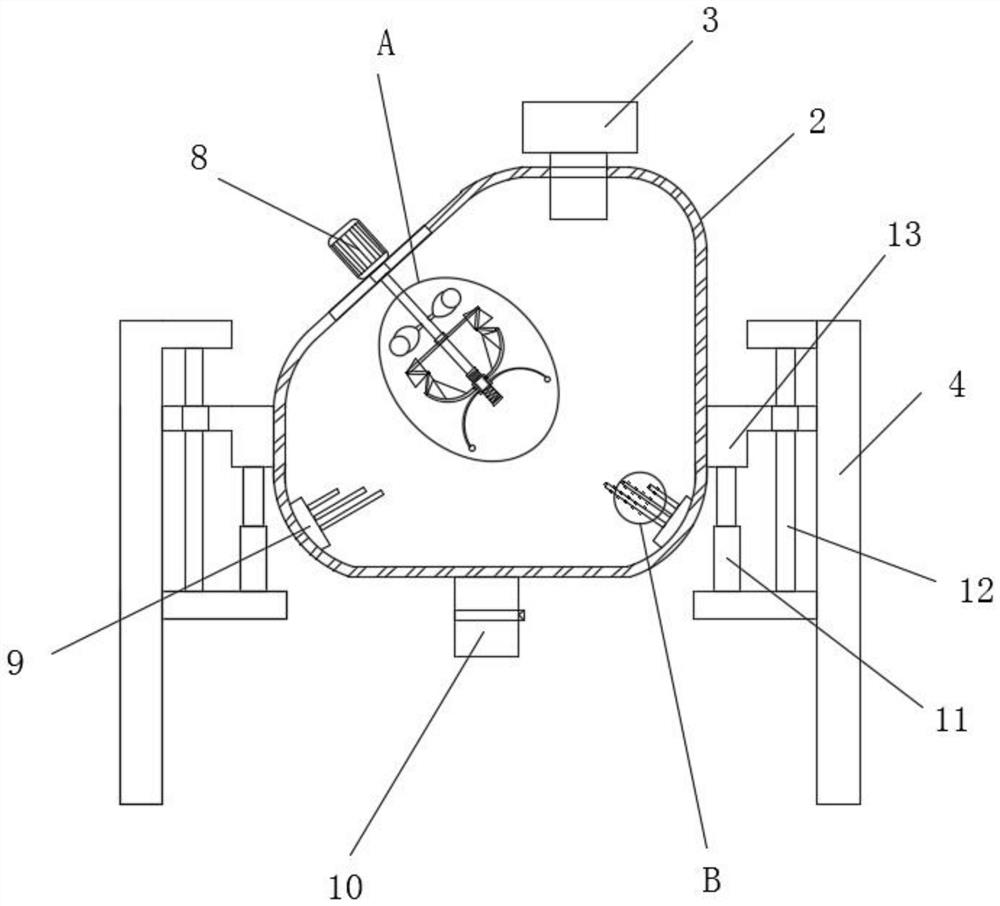

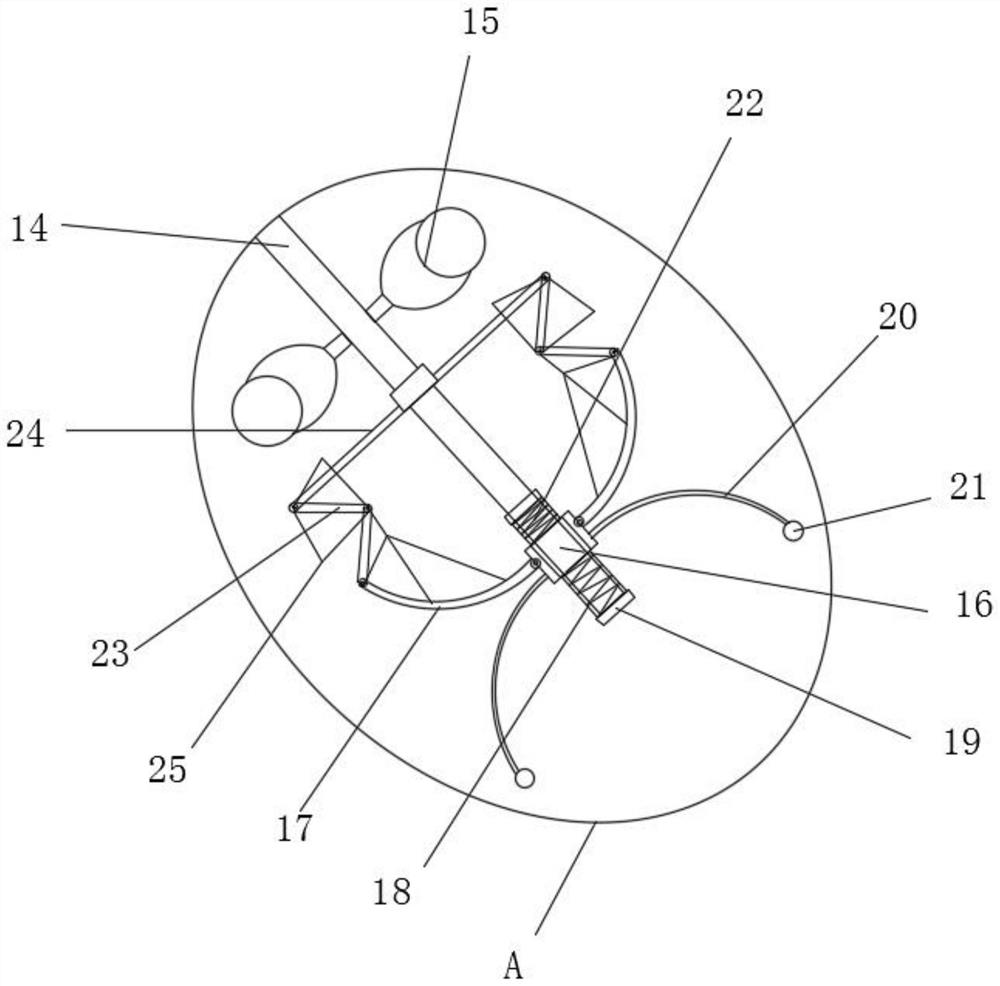

[0031] Such as Figure 1-6 As shown, the present invention provides a carbonated beverage processing and blending device, including a main device 1, a blending tank 2 and a discharge assembly 3, the interior of the main device 1 is provided with a blending tank 2, and the upper surface of the blending tank 2 is provided with a discharge Component 3, the outer wall of the blending tank 2 is provided with an external bracket 4, the inner wall of the blending tank 2 is movably connected with a linkage stirring rod 14, the bottom end of the linkage stirring rod 14 is fixedly connected with a limit block 19, and the outer wall of the linkage stirring rod 14 is fixedly connected Mounting rod 24 is arranged, and the upper surface of discharging assembly 3 is fixedly connected with storage grid 29, and the inner wall of storage grid 29 is provided with blanking control assembly 30, and the inner wall of blanking control assembly 30 is fixedly connected with barrier frame 31, barrier fr...

Embodiment 2

[0033] Such as Figure 1-6As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the bottom surface of the barrier frame 31 is fixedly connected with a bottom column 32, and the upper surface of the airbag 33 is provided with a chute 34, and the chute 34 The inner wall of the inner wall is movably connected with the outer wall of the barrier frame 31, one side of the discharging assembly 3 is fixedly connected with a four-point air delivery pipe 6, the outer end of the four-point air delivery pipe 6 is fixedly connected with an air pump 5, and the outer wall of the four-point air delivery pipe 6 is fixedly connected There is a control valve, and the outer wall of the mixing tank 2 is fixedly connected with a supporting outer ring 13, and the upper surface of the supporting outer ring 13 is provided with a sliding hole, and the inner wall of the sliding hole is movably connected with a guide sliding rod 12, and the top of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com