Water-based household appliance color steel surface paint coating method and coating device

A technology for coating devices and home appliances, which is applied in the direction of surface coating liquid devices, coatings, pre-treated surfaces, etc., can solve problems such as damage, and achieve the effects of increasing uniformity, increasing resistance to damage, and increasing coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

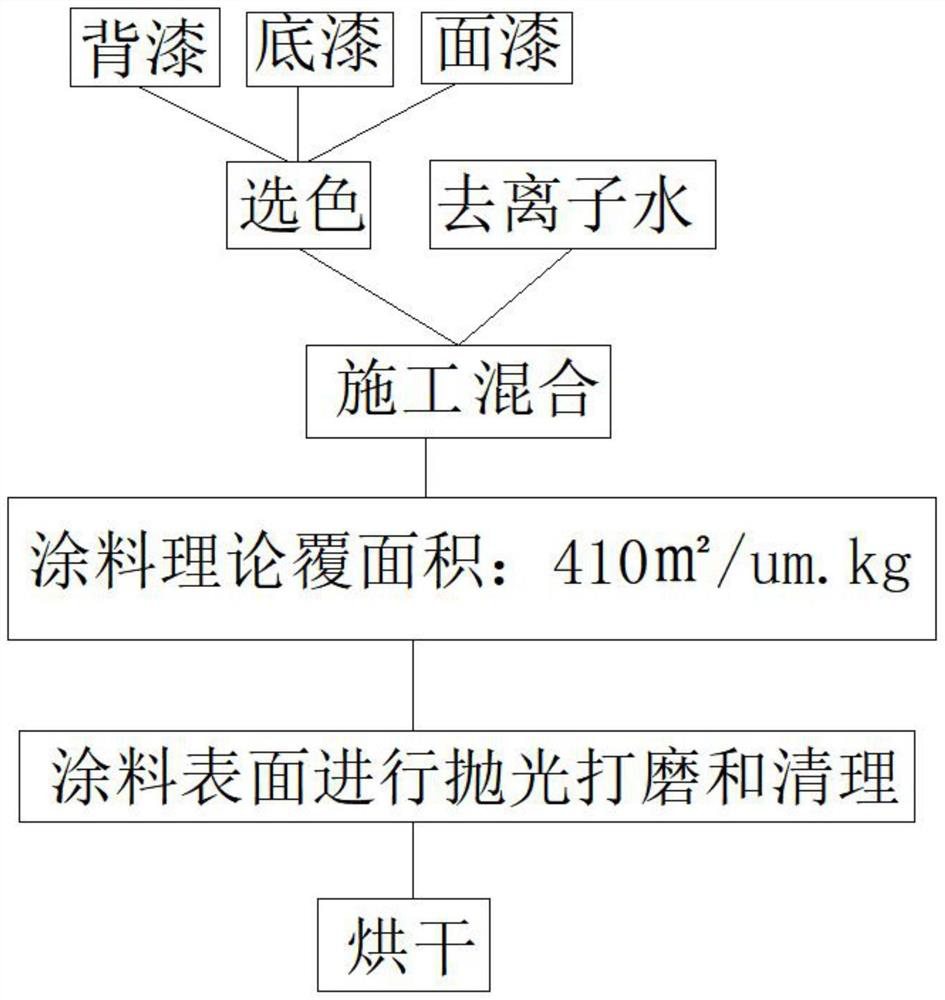

[0061] see figure 1 , a water-based home appliance color steel surface paint coating method, including back paint application, primer application and top paint application, and the back paint, primer and top paint are applied in batches in a manner of one coating and one baking.

[0062] Specifically, the back paint, primer and top paint are respectively color-selected, and the operator can select the color of the paint, and then it can be coated into a suitable R&D, neutralized by a diluent, and neutralized in deionized water by the diluent. , It can avoid the impact of water ions on the thinner, select the specific gravity, paint and dry treatment.

[0063] Wherein, the primer is selected from the paint material, and the paint material is mixed with a diluent, the diluent is selected from deionized water, the back paint of the home appliance color steel is scraped off, and the primer is applied, and the primer is kept at Between the dry film 12μm and the wet film 16μm, by s...

Embodiment 2

[0070] refer to figure 1 , the primer is selected from the paint, and the paint is mixed with a thinner, the thinner is deionized water, the back paint of the home appliance color steel is scraped off, and the primer is applied, and the primer is kept in a dry state. Between the film 20μm and the wet film 30μm, by selecting the paint before the coating process, the color to be coated can be adjusted, and the inside of the selected paint can be driven to add deionized water, and the paint and paint can be driven. Mix the deionized water evenly to avoid the reaction of ions inside the mixed liquid, which will affect the coating effect, and scrape off the back paint of the home appliance color steel, and apply the primer. The primer is kept at a dry film of 20 μm Between 30μm and the wet film, it can avoid the influence of the back paint of the home appliance color steel on the primer coating.

[0071] refer to figure 1 , after the primer is applied, the primer is dried for 30 ...

Embodiment 3

[0076] Wherein, the primer is selected from the paint material, and the paint material is mixed with a diluent, the diluent is selected from deionized water, the back paint of the home appliance color steel is scraped off, and the primer is applied, and the primer is kept at Between the dry film 17μm and the wet film 23μm, by selecting the paint before the coating process, the color to be coated can be adjusted, and the selected paint can be driven to add deionized water inside, and the paint can be driven Mix evenly with deionized water to avoid the reaction of ions inside the mixed liquid, which will affect the coating effect, and scrape off the back paint of the home appliance color steel, and apply the primer, which remains on the dry film Between 17μm and wet film 23μm, it can avoid the influence of the back paint of home appliance color steel on the primer coating.

[0077] refer to figure 1 , after the primer is applied, the primer is dried for 30 seconds, the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com