Auxiliary feeding device for curled plate blank of plate rolling mill and using method of auxiliary feeding device

A technology of auxiliary feeding and plate rolling mill, which is applied in the field of metallurgical plate rolling to achieve the effect of small material loss, low production cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

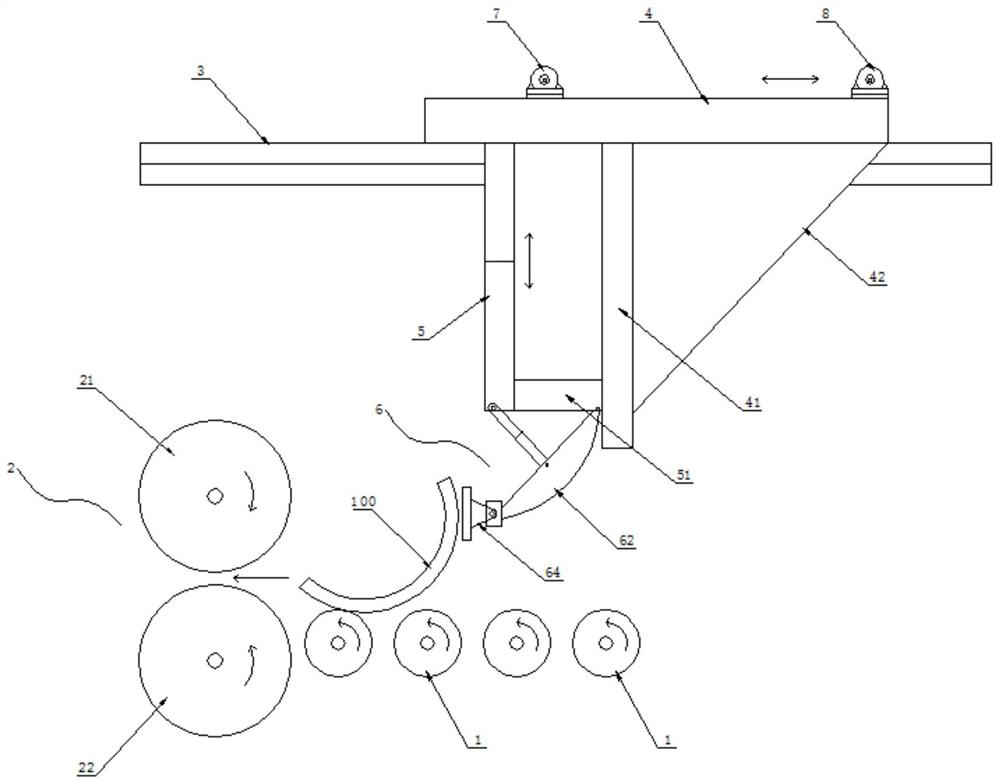

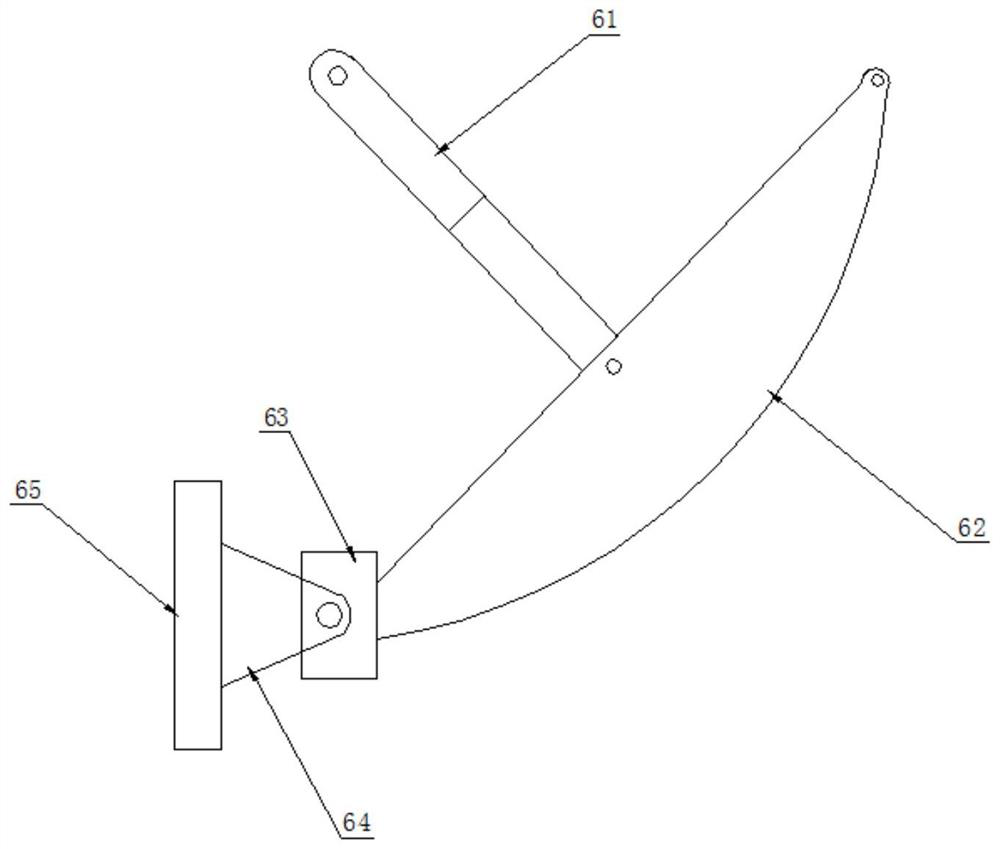

[0021] combined with Figure 1-2 , the specific embodiment of the present invention is described as follows:

[0022] Such as Figure 1-2 As shown, an auxiliary feeding device for curling slabs in a plate rolling mill includes a conveying roller 1, a rolling mill pressure roller 2, an overhead cloud rail 3, a frame 4, and a lifting device 5. There are several conveying rollers 1 that are parallel to each other and located at the same On a horizontal line, the rolling mill press roll 2 is arranged at the end of several delivery rolls 1 . Rolling mill pressure roll 2 is made up of top pressure roll 21 and bottom pressure roll 22, and top pressure roll 21 is arranged on the top of bottom pressure roll 22, and the axle centers of top pressure roll 21 and bottom pressure roll 22 are parallel to each other, and the direction of rotation is opposite.

[0023] The overhead cloud rail 3 is arranged above the conveying roller 1, and the frame 4 is installed on the overhead cloud rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com