Die for aluminum alloy ship

An aluminum alloy and mold technology, which is applied in the field of aluminum alloy boat molds, can solve problems such as disorderly distribution, inability to guarantee the stability and safety of aluminum alloy plate stamping processing, and positional deviation of aluminum alloy plate, so as to improve the efficiency of use performance, improve the convenience of use, improve the effect of stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

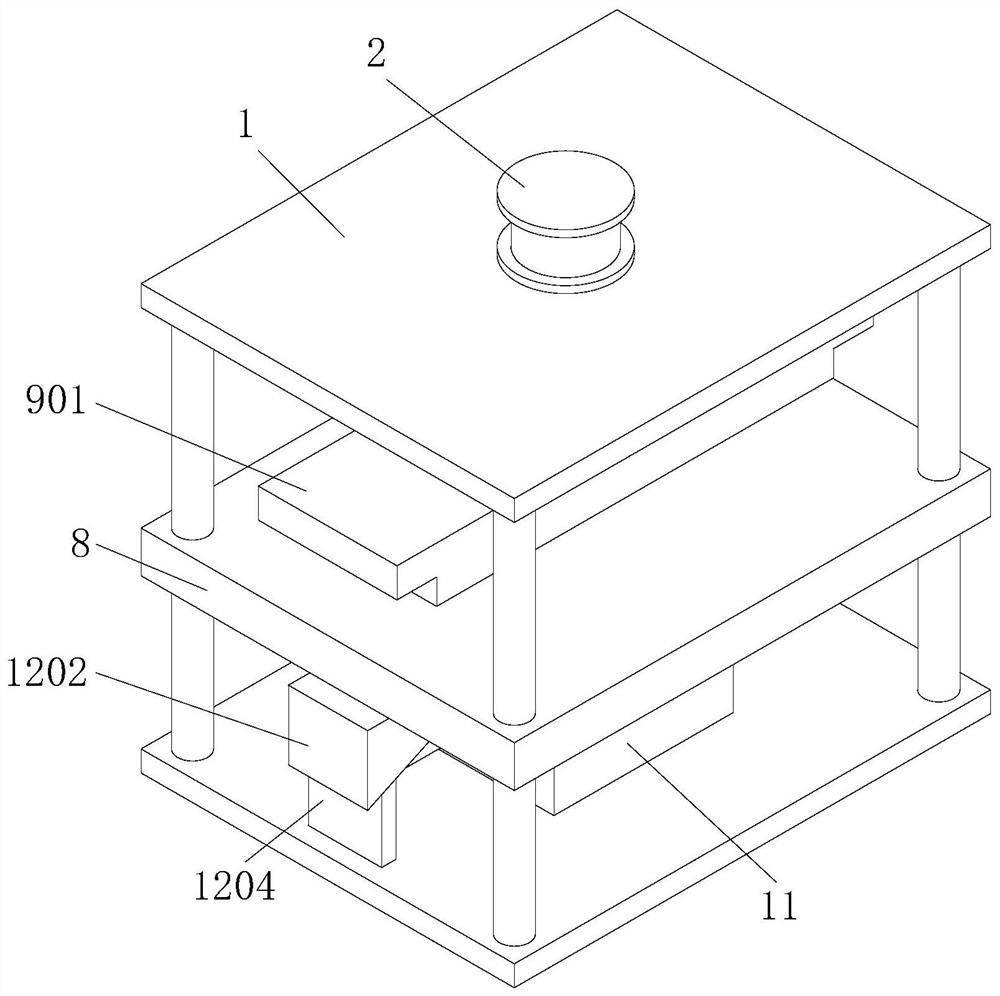

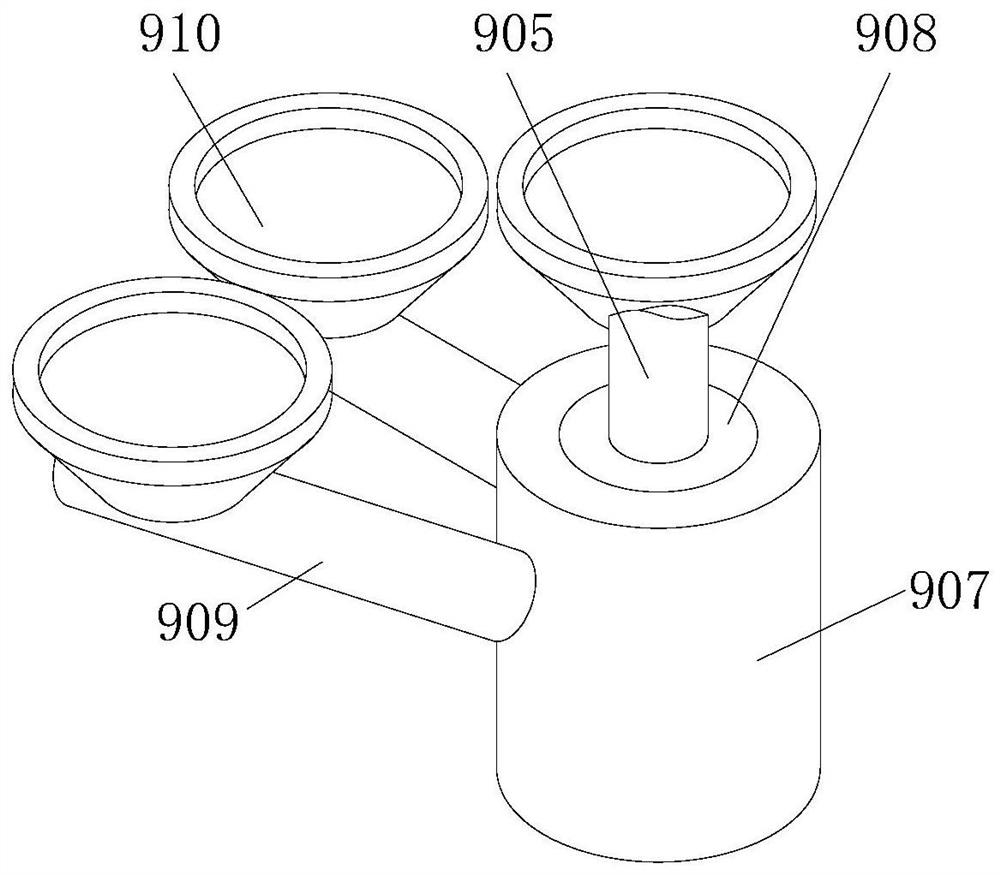

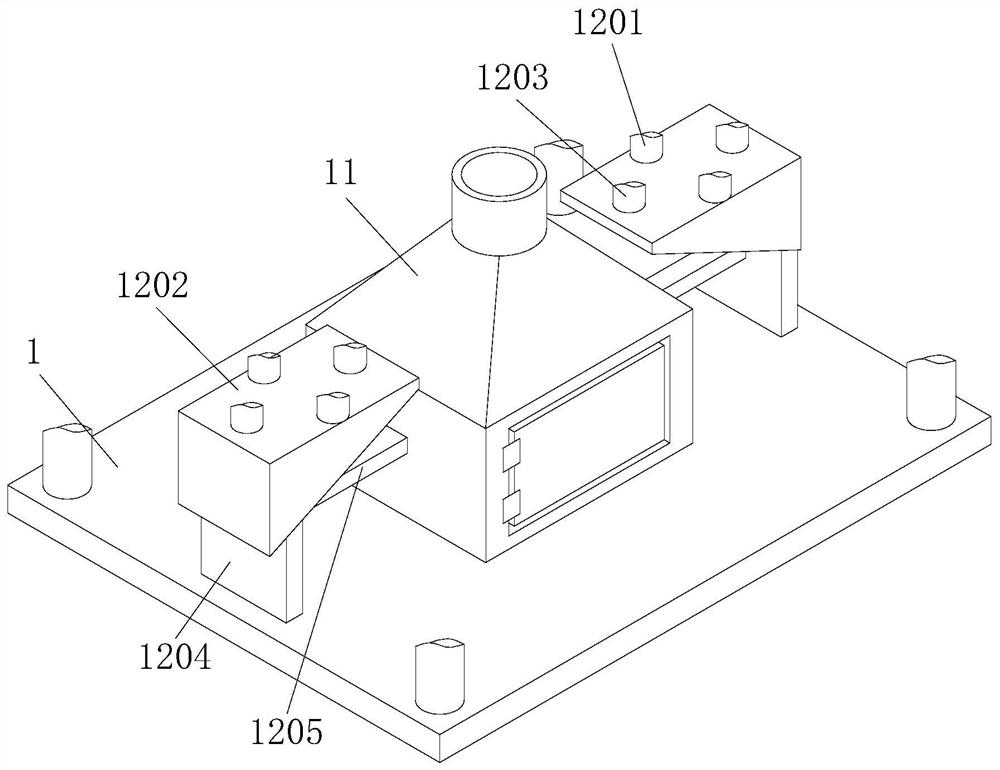

[0038] Such as Figure 1-11 As shown, a mold of an aluminum alloy ship includes a mold shell 1, a hydraulic cylinder 2 is installed on the top surface of the mold shell 1 with bolts, a hydraulic rod 3 is connected to the hydraulic cylinder 2, and the bottom end of the hydraulic rod 3 is welded and fixed with an upper Die fixing plate 4, punching tool 5 and telescopic sleeve rod 6 are welded and fixed on the bottom end surface of upper mold fixing plate 4, fixed spring 7 is welded and fixed in telescopic sleeve rod 6, and lower mold placement plate 8 is welded and fixed in mold shell 1 , the positioning and fixing assembly 9 is installed on the lower mold placing plate 8, the positioning and fixing assembly 9 is connected with an automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com