Wire feeding wheel cover plate device for suspension spring production

A technology of cover plate device and suspension spring, which is applied in the direction of manufacturing springs from wires, applications, household appliances, etc., which can solve the problems of loosening of wire feeding wheel fastening bolts, affecting production efficiency, and equipment damage to fastening bolts, etc., to reduce Repair and maintenance time, improvement of labor efficiency, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

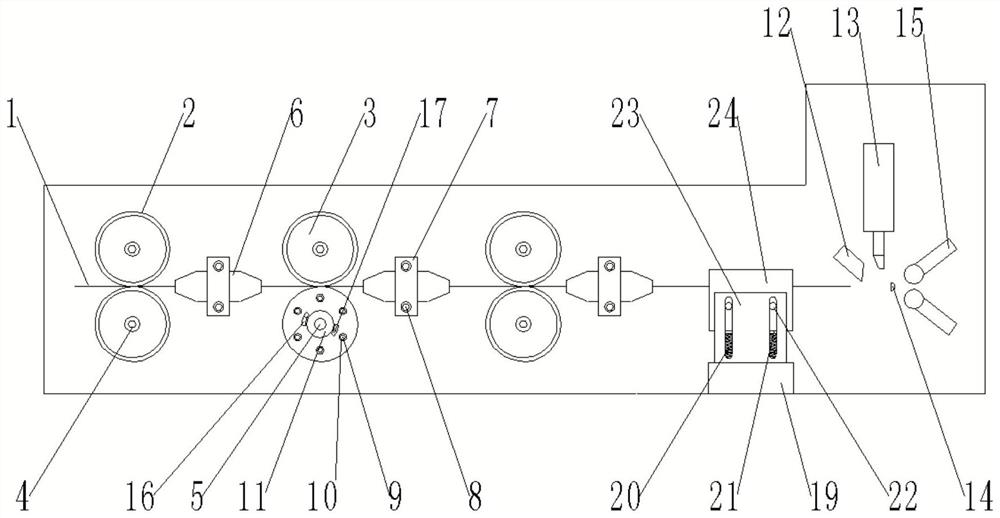

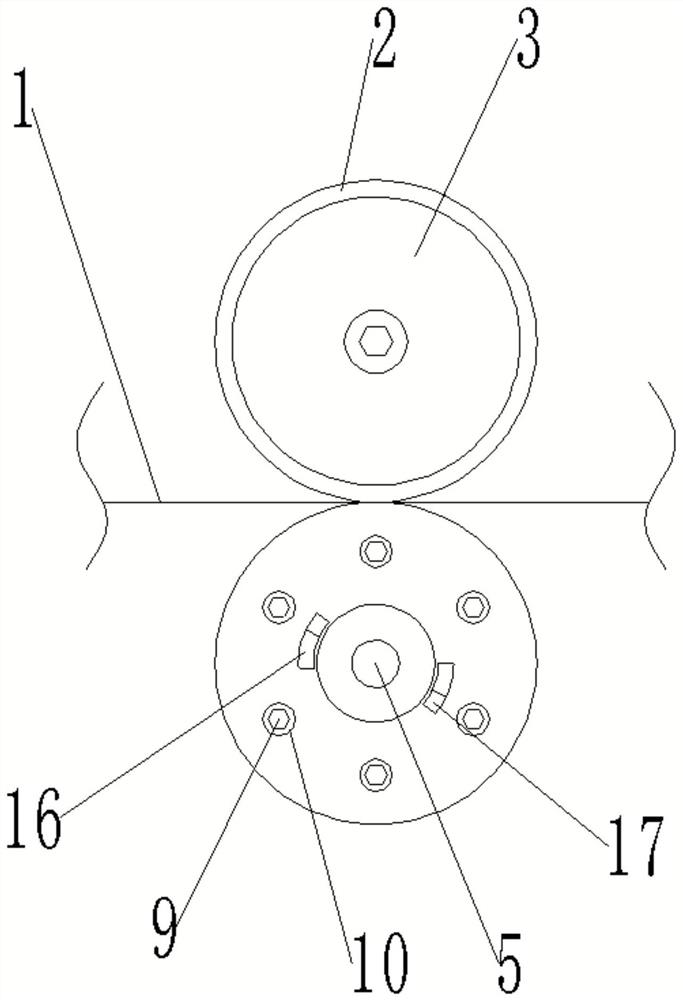

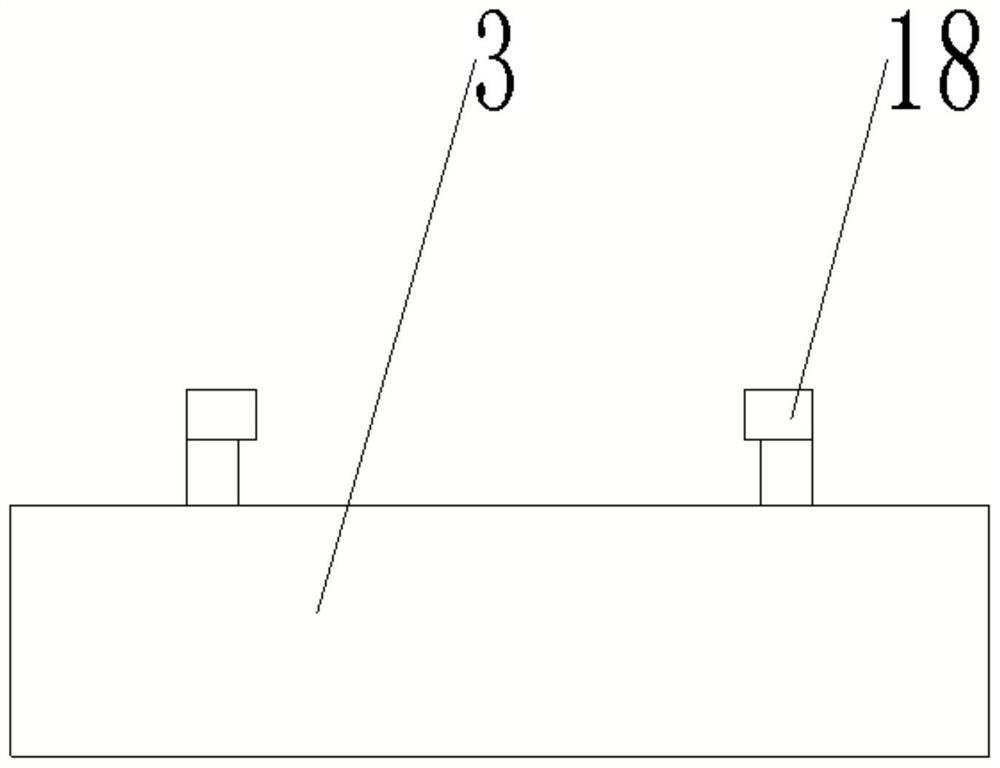

[0039] Please refer to the attached Figure 1-3 , in the specific implementation process, a wire feeding wheel cover device for suspension spring production includes a spring steel wire 1, a number of wire feeding wheels 2 and spring equipment, and the spring steel wire 1 is fixedly installed in the wire groove of the wire feeding wheel 2 , the wire feeding wheel 2 is installed on the spring device;

[0040] The spring device is provided with a guide assembly, the wire feeding wheel 2 is provided with a pressing and fixing assembly, the spring device is provided with a processing and forming assembly, and the spring device is provided with a buffer assembly;

[0041] It should be noted that the spring equipment is equipped with a wire feeding wheel 2. When the wire feeding wheel 2 conveys the steel wire, two wire feeding wheels 2 are selected to be distributed up and down as a group, and the spring steel wire 1 is fixed in the upper and lower wire feeding wheel 2 grooves. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap