Buckling connecting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

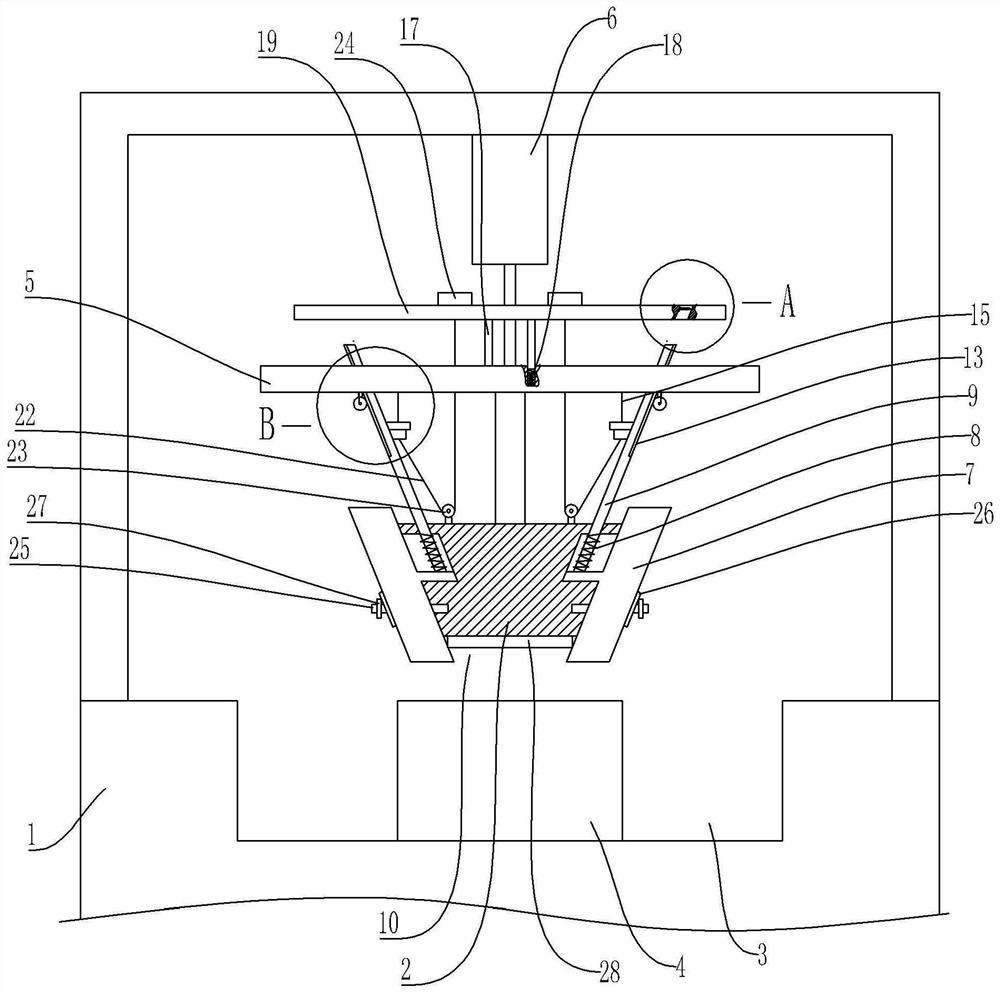

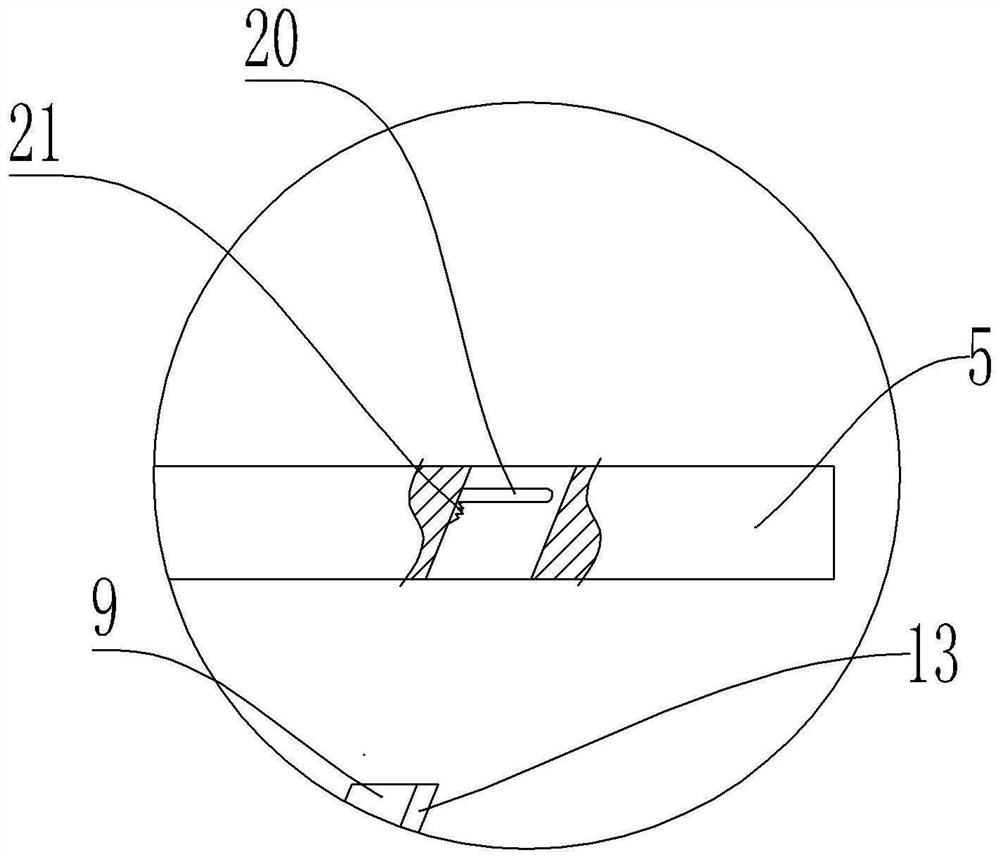

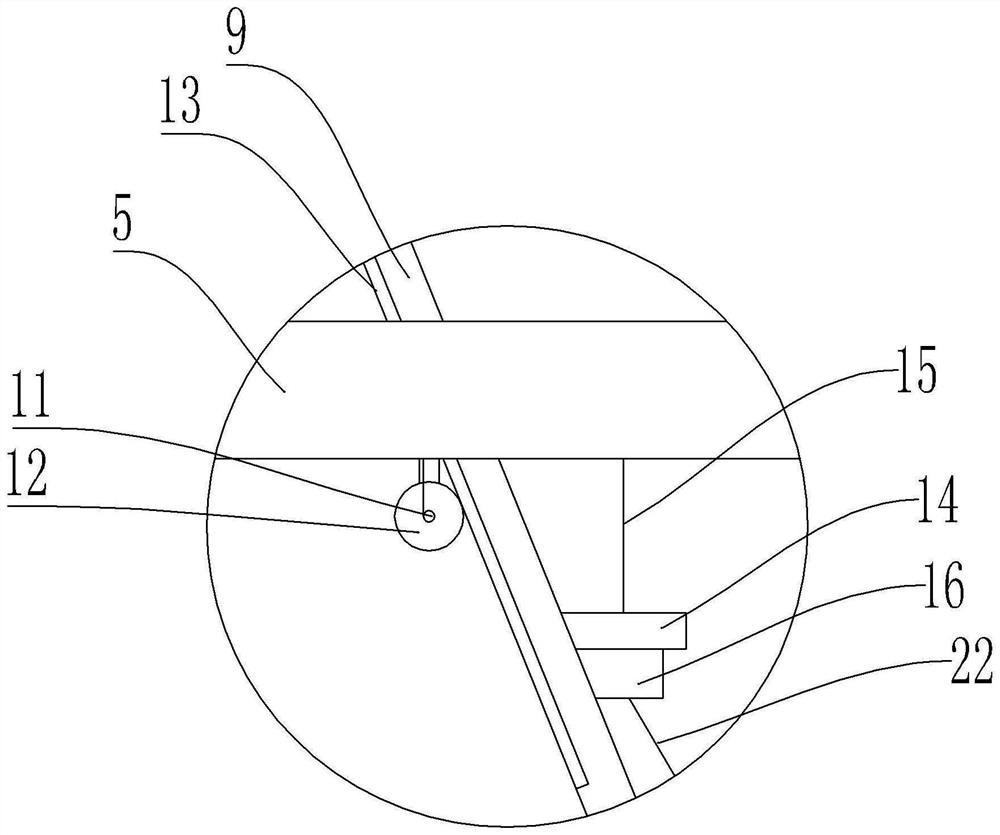

[0031] Basic as attached figure 1 , attached figure 2 And attached image 3 Shown: a buckle connection machine, including a workbench 1, a pressing block 2 and a drive mechanism, an auxiliary groove 3 is opened on the workbench 1, and an auxiliary table 4 is fixedly connected to the middle of the auxiliary groove 3; The top is flush with the top of the workbench 1, and the auxiliary table 4 is located on the motion track of the pressing block 2. It also includes a lifting platform 5, the driving mechanism drives the lifting platform 5 to move vertically, and the pressing block 2 is fixedly connected to the bottom of the lifting platform 5; in this embodiment, the driving mechanism includes a support plate and a cylinder 6, and the support plate is fixed on the workbench 1 Above, the cylinder 6 is affixed to the cardboard, and the cylinder 6 is located above the lifting platform 5, and the output shaft of the cylinder 6 is affixed to the top of the lifting platform 5.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com