Stirring device for mortar production and processing

A mixing device and mortar technology, which is applied to cement mixing devices, clay preparation devices, cleaning methods and utensils, etc., can solve the problems of inconvenient scraping and cleaning of mortar, affecting the use effect, falling to the ground, etc., so as to increase the practicability. , Easy to disassemble, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

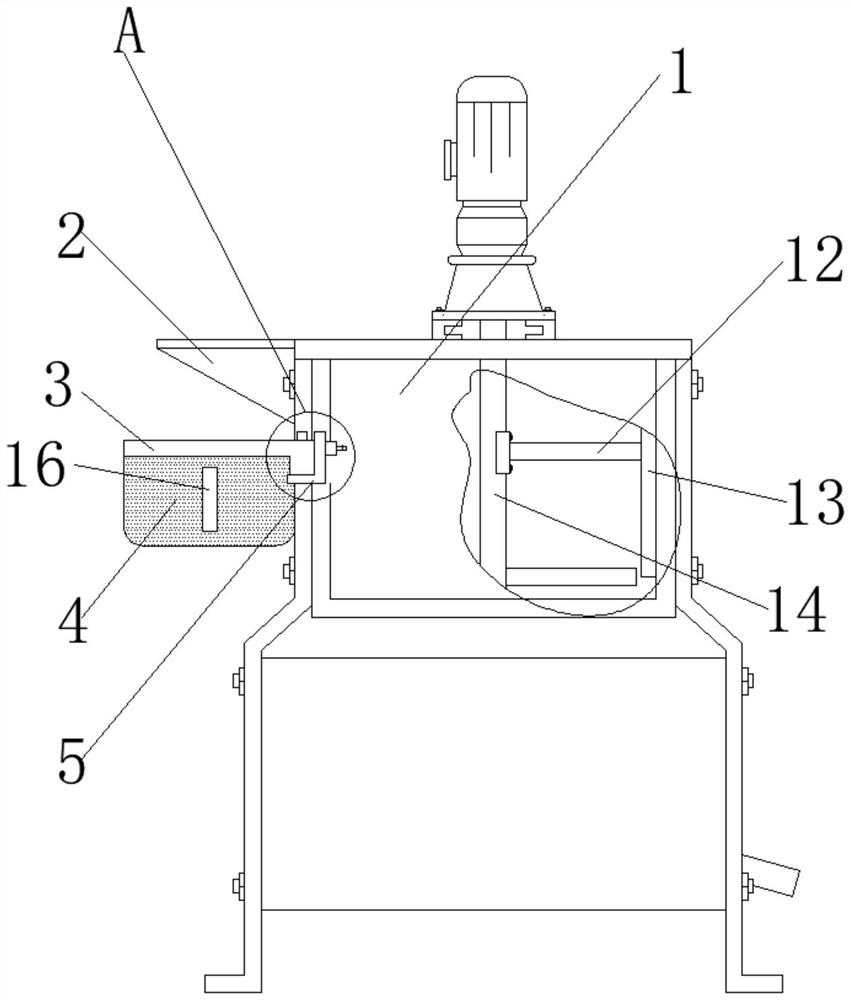

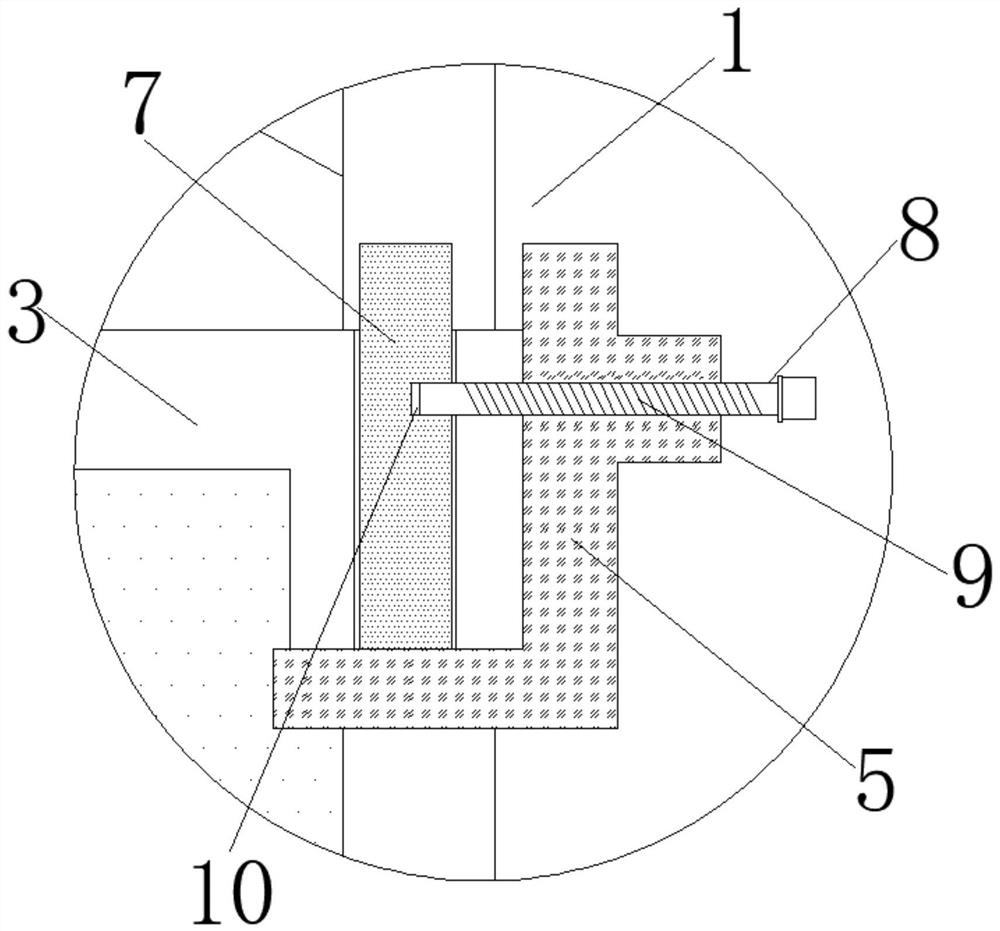

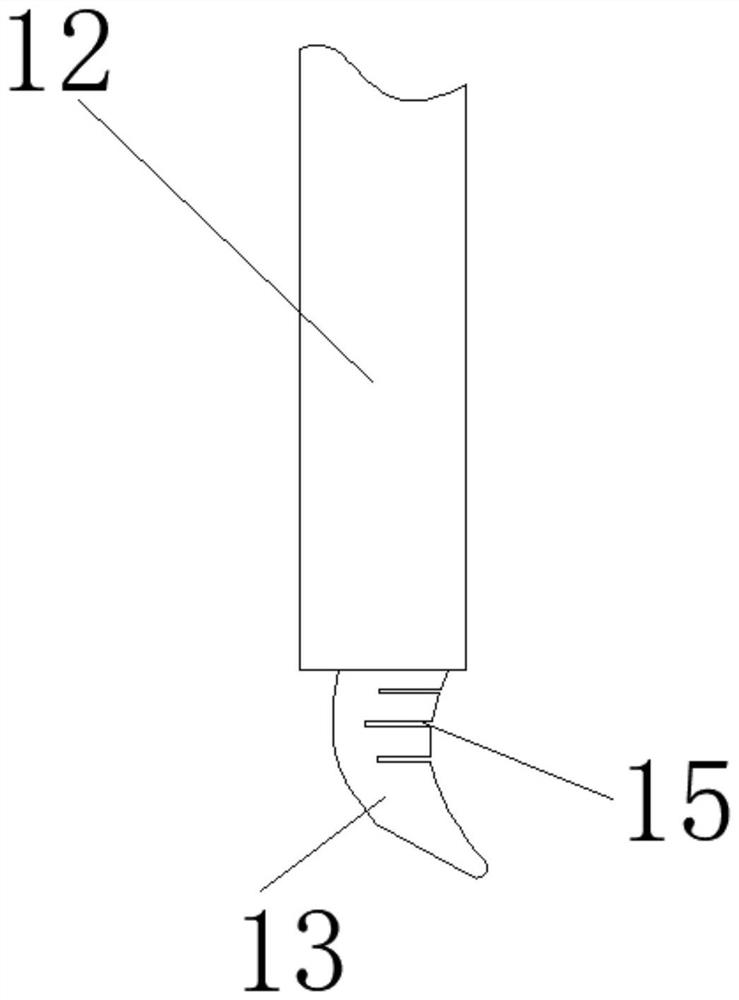

[0022] see Figure 1-Figure 3 , the present invention provides a technical solution: a mixing device for mortar production and processing, comprising a mixer body 1, a material guide plate 2 is arranged on the upper surface of one end of the mixer body 1, a stirring motor is arranged at the top of the mixer body 1, and a stirring motor is arranged at a lower end There is a stirring rod 14, the lower end of the side surface of the stirring rod 14 is provided with a stirring plate, the front surface of the mixer body 1 is fixed with a mounting block 5, and a connecting column 7 is fixed on the mounting block 5, so as to facilitate the installation of the collection tank body 4, and the connecting column 7 outside An installation frame 3 is provided, and a connection hole is opened on the inside of the installation frame 3, and the installation frame 3 and the connection column 7 are matched and connected through the connection hole, which is convenient for quickly connecting the ...

Embodiment 2

[0030] see Figure 1-Figure 4 , the present invention provides a technical solution: a mixing device for mortar production and processing, comprising a mixer body 1, a material guide plate 2 is arranged on the upper surface of one end of the mixer body 1, a stirring motor is arranged at the top of the mixer body 1, and a stirring motor is arranged at a lower end There is a stirring rod 14, the lower end of the side surface of the stirring rod 14 is provided with a stirring plate, the front surface of the mixer body 1 is fixed with a mounting block 5, and a connecting column 7 is fixed on the mounting block 5, so as to facilitate the installation of the collection tank body 4, and the connecting column 7 outside A mounting frame 3 is provided, and a connecting hole is provided on the inner side of the mounting frame 3. The mounting frame 3 and the connecting column 7 are connected through the connecting hole, which is convenient for quickly connecting the mounting frame 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com