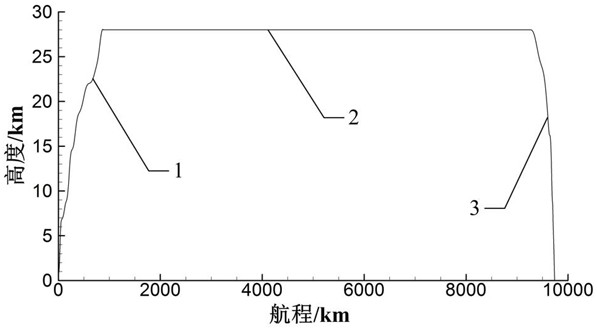

Aerodynamic layout and design method of air-breathing hypersonic aircraft with high lift-drag ratio

An aerodynamic layout, hypersonic technology, applied in supersonic aircraft, motor vehicles, aircraft control, etc., to improve the flow separation problem, ensure wide-speed range flight performance, and efficient high-speed cruise flight capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

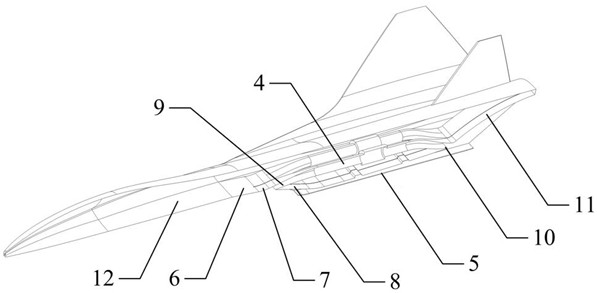

[0074] An aerodynamic layout of an air-breathing hypersonic aircraft with a high lift-to-drag ratio, including the aerodynamic layout of the airframe / inner runner; in the aerodynamic layout of the fuselage / inner runner, from front to back are the front body pre-compression surface 12 and the first-stage external compression Surface 6, secondary external compression surface 7, tertiary external compression surface 8, ram flow channel 5, first exhaust nozzle 10 and second exhaust nozzle 11, inlet splitter plate 9 is located inside secondary external compression surface 7 , the turbine runner 4 is connected in parallel above the ram runner 5 .

Embodiment 2

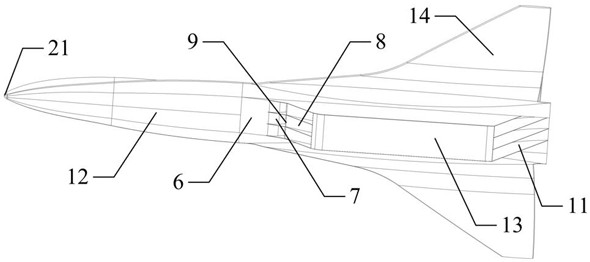

[0076] On the basis of Embodiment 1, including the aerodynamic layout of the windward side; in the aerodynamic layout of the windward side, the front end of the fuselage is the rounded head 21, followed by the front body pre-compression surface 12, the first-stage external compression surface 6, The secondary external compression surface 7, the tertiary external compression surface 8, the TBCC engine casing 13 and the tail nozzle 11, the inlet diverter plate 9 is located inside the secondary external compression surface 7, and the wings 14 are located on both sides of the rear fuselage .

Embodiment 3

[0078] On the basis of Embodiment 1 or 2, including the aerodynamic layout of the leeward side; in the aerodynamic layout of the leeward side, the shape of the longitudinal section is controlled by the fuselage ridge line 19 on the leeward side, and the shape of the transverse section is controlled by the control curve 20 of the fuselage cross section , the two sides of the fuselage are side strip wings 16 and wings 14, the two are connected front and back, and the connecting section is smoothly transitioned; Along the transition zone and the leading edge of the wing 14 are rounded, the combined wing of the side strip wing 16 and the wing 14 is located on both sides of the fuselage, and is smoothly connected with the fuselage through the wing-body fusion surface 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com