Circulating water purifying and conveying integrated device for assembled air-conditioning water system and operation method of circulating water purifying and conveying integrated device

An integrated device and circulating water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of long commissioning cycle, low degree of integration of equipment installation, algae breeding and Legionella and other problems, to achieve the effect of facilitating project implementation and operation and maintenance, shortening the installation and commissioning period, and making installation and commissioning compact and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

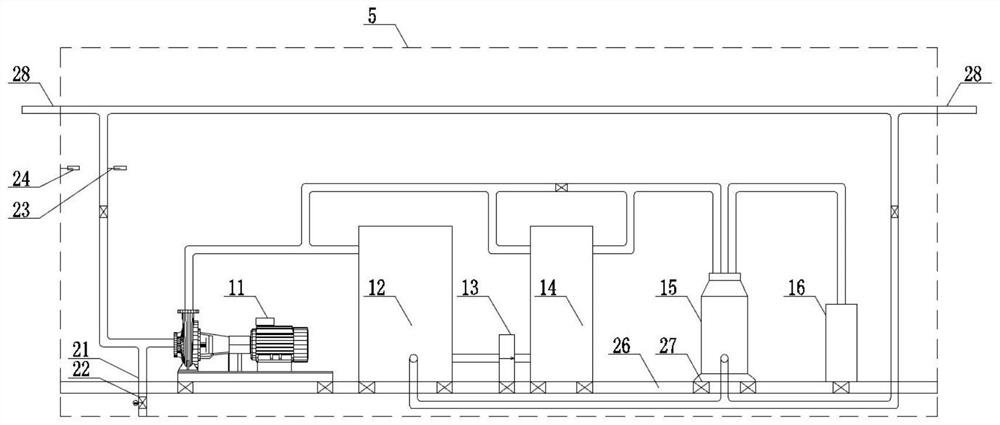

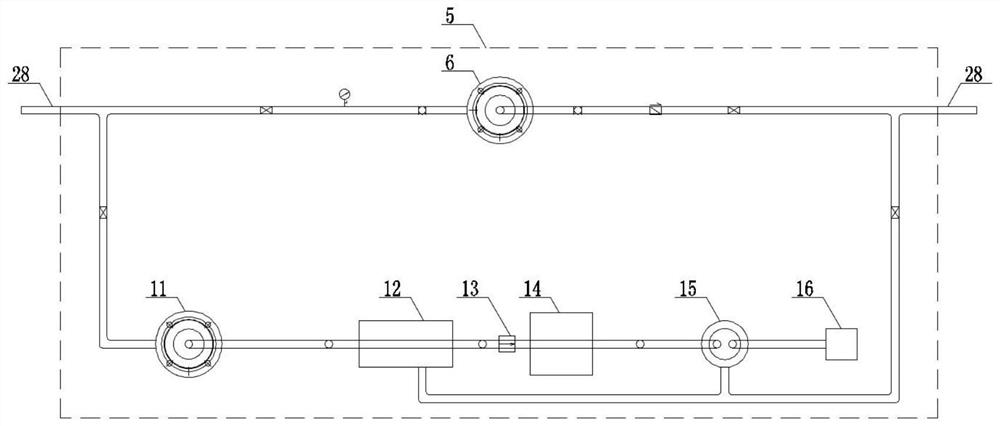

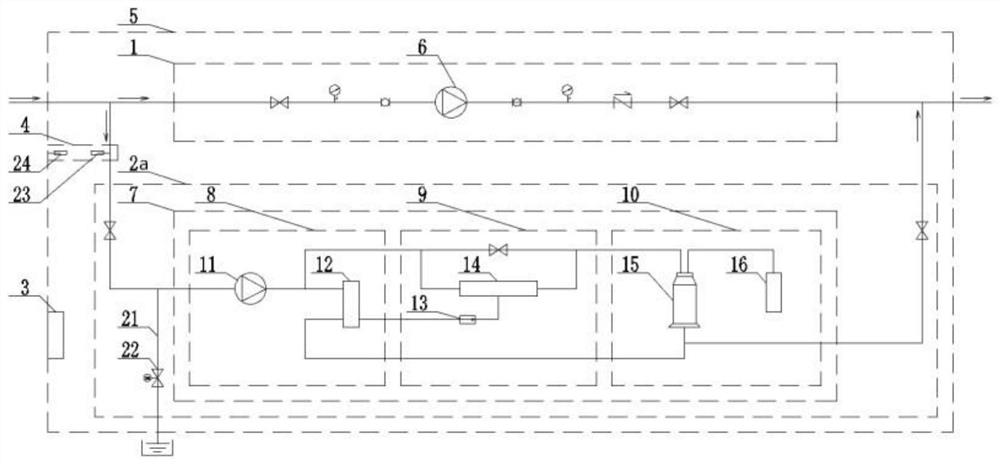

[0068] A prefabricated air-conditioning water system circulating water purification and delivery integrated device, including a modular box 5, a control unit 3 and a monitoring unit 4 are arranged in the modular box 5, and a control unit 3 and a monitoring unit 4 are arranged in the modular box 5 : circulating water delivery unit 1, which is installed on the main circulation pipeline, said circulating water delivery unit 1 comprises circulating water pump 6, pipeline and accessories; circulating water purification unit 2, which is connected with circulating water delivery unit 1, said circulating water The purification unit 2 is divided into three types according to the water treatment process: type A / type B / type C. Specifically: the circulating water purification unit 2 includes one of the type A purification unit 2a, the type B purification unit 2b, and the type C purification unit 2c. One or more, users can customize according to actual needs.

[0069] In this embodiment, t...

Embodiment 2

[0084] Such as Figure 1-3 As shown, the A-type purification unit 2a is installed in parallel with the circulating water delivery unit 1, the water inlet end of the A-type purification unit 2a is connected to the water inlet end of the circulation water delivery unit 1, and the A-type purification unit 2a The water outlet is connected to the water outlet of the circulating water delivery unit 1 .

[0085] Further, it can also be considered in this embodiment that the A-type purification unit 2a includes advanced oxidation water treatment equipment 7, pipelines and accessories, and the advanced oxidation water treatment 7 equipment includes an ozone generator 8 and an ozone mixing device 9 With the ozone treatment device 10, the three are connected in sequence.

[0086] In this embodiment: the A-type purification unit 2a extracts 1% to 5% of circulating water from the main circulation pipeline, and the circulating water is sucked into the ozone generator 12 by the booster pump...

Embodiment 3

[0091] Such as Figure 4-6 As shown, the B-type purification unit 2b is installed in series with the circulating water delivery unit 1, and the water inlet end of the B-type purification unit 2b is connected to the water outlet of the circulating water delivery unit 1, that is, the circulating water in the main circulation pipeline It passes through the circulating water delivery unit 1 and the B-type purification unit 2b in sequence.

[0092]Furthermore, it can also be considered in this embodiment that the B-type purification unit 2b includes physical and chemical full-effect water treatment equipment 17, pipelines and accessories, and the physical and chemical full-effect water treatment equipment 17 includes a full-effect water processor 18 and An intelligent dosing device 19, the intelligent dosing device 19 is arranged near the water outlet of the main circulation pipeline. Specifically: according to the flow direction of the circulating water, the full-effect water pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com