Construction method for constructing large and thick collapsible loess foundation by using profile steel cement soil stirring wall

A cement-soil mixing wall and collapsible loess technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of insufficient density of grouting in the gaps of section steel, and reduce the amount of earthwork excavation, The construction operation is simple and the effect of improving the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

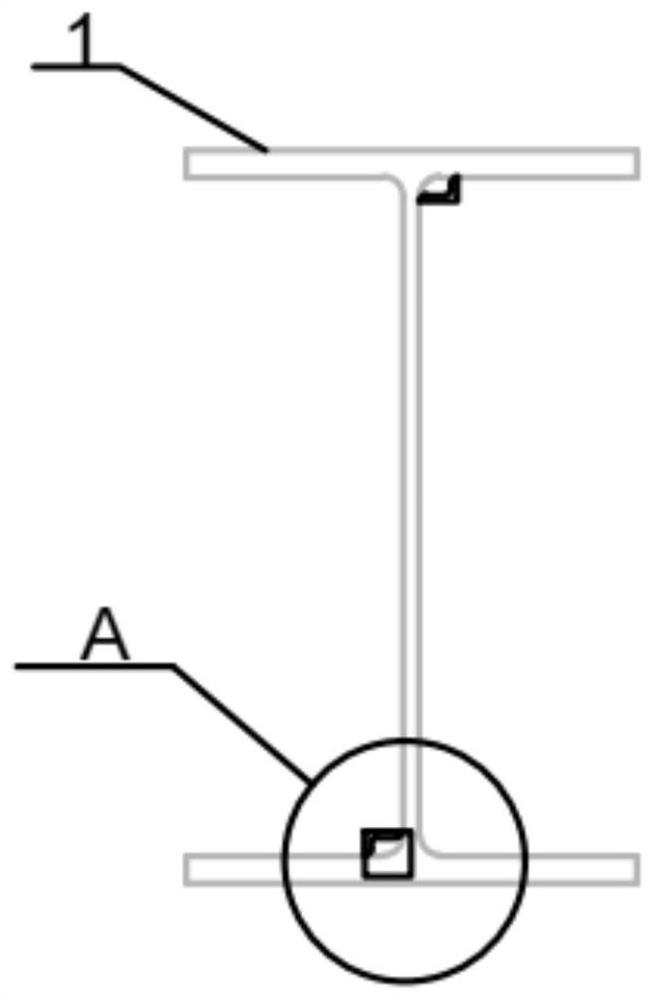

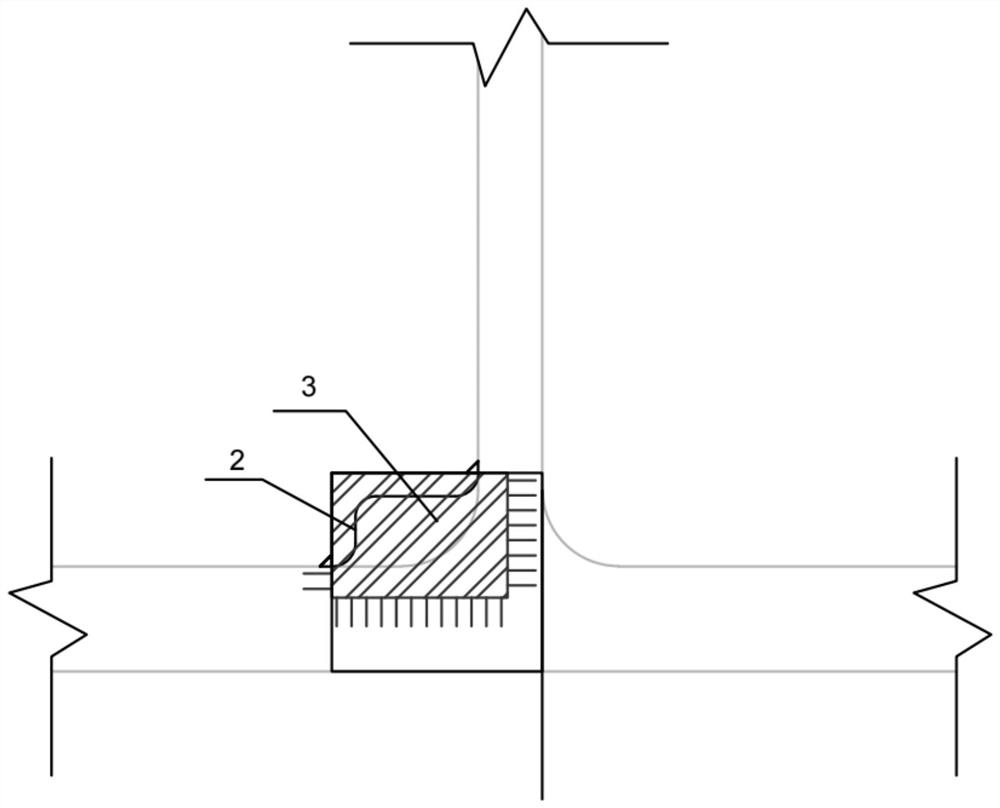

[0042] Such as figure 1 and figure 2 As shown, the present invention provides a construction method for constructing a thick collapsible loess foundation using a steel cement-soil mixing wall, which is realized by the following equipment: comprising a steel profile 1, which is an I-beam; the steel profile 1 includes an integrally formed The web 11, the first flange 12 and the second flange 13;

[0043] Both sides of the web 11 are provided with angle steel 2, and the angle steel 2 is fixedly connected with the first flange 12 and the web 11 or is fixedly connected with the second flange 13 and the web 11; the angle steel 2 The bottom is provided with a blocking steel plate 3, and the blocking steel plate 3 is a rectangular steel plate, and the rectangular steel plate is fully welded to the angle steel 2 and the section steel respectively.

[0044] Such as Figure 5 As shown, the construction equipment also includes a split grouting pipe 5; the body part of the split grouti...

Embodiment 2

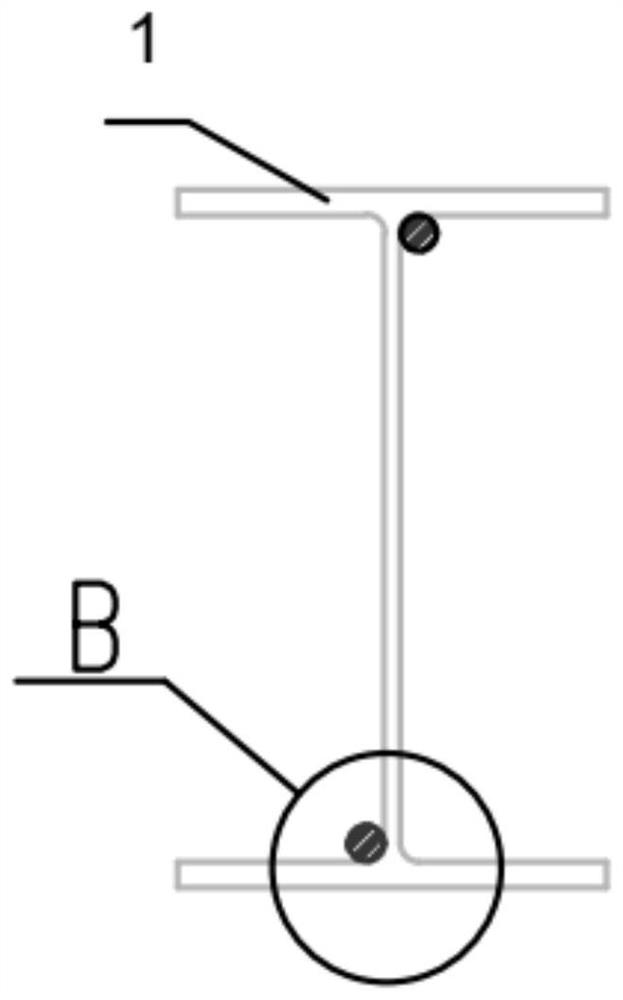

[0047] On the basis of Example 1, the combination of angle 1 and plugging steel plate can be replaced by round steel 4. For details, please refer to image 3 and Figure 4 : the round steel 4 is fixedly connected with the first flange 12 and the web 11 or is fixedly connected with the second flange 13 and the web 11; wherein the round steel 4 is a cylindrical structure.

[0048] Specifically, the above construction methods, such as Figure 6 and Figure 7 shown, including the following steps:

[0049] S1. By changing the section shape of the section steel (welding L angle steel or round steel at the position of the section steel web), and combining the construction plan of the section steel cement-soil mixing pile to complete the mixing pile, lower the section steel with the changed section into the triaxial mixing pile 7 in the groove , fill the trench with cement soil;

[0050] S2. The underground main structure is completed and reaches the design strength, and the space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com