Special drill bit for rotary steering of superhard formation

A rotary steerable, hard formation technology, applied in the direction of drilling tools, drilling equipment, earthwork drilling and mining, etc., can solve the problems of untimely heat dissipation of the drill bit, poor drilling effect, etc., and achieve the effect of preventing mud bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

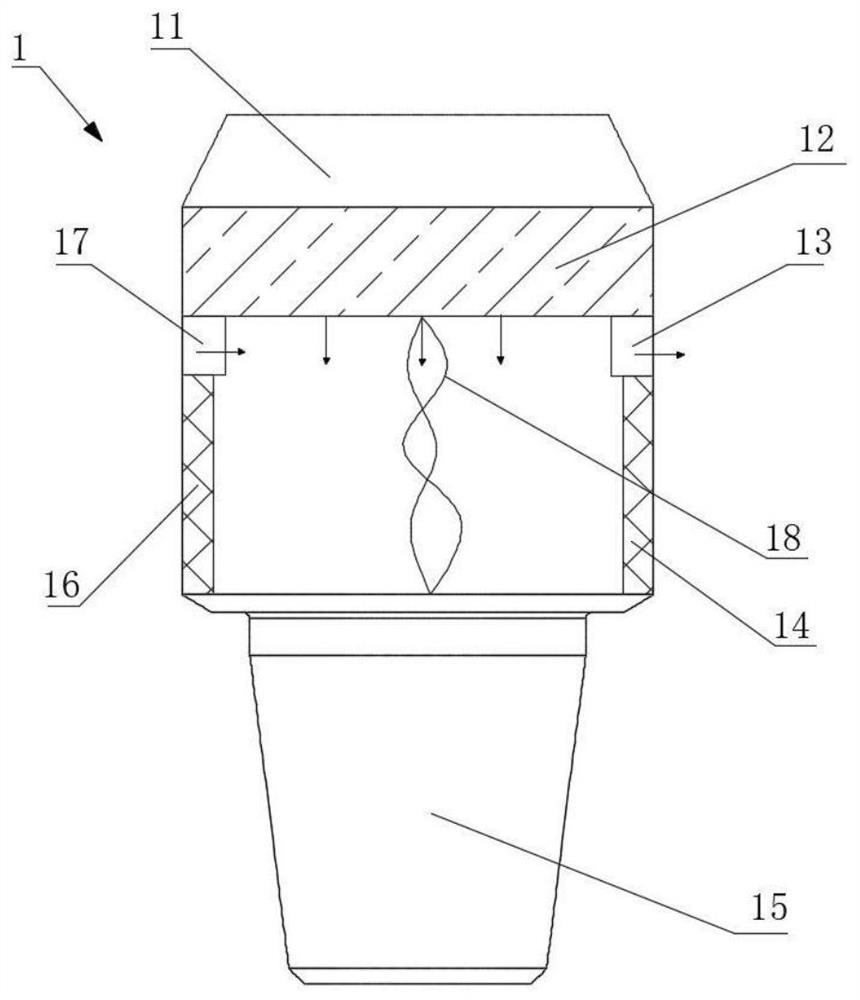

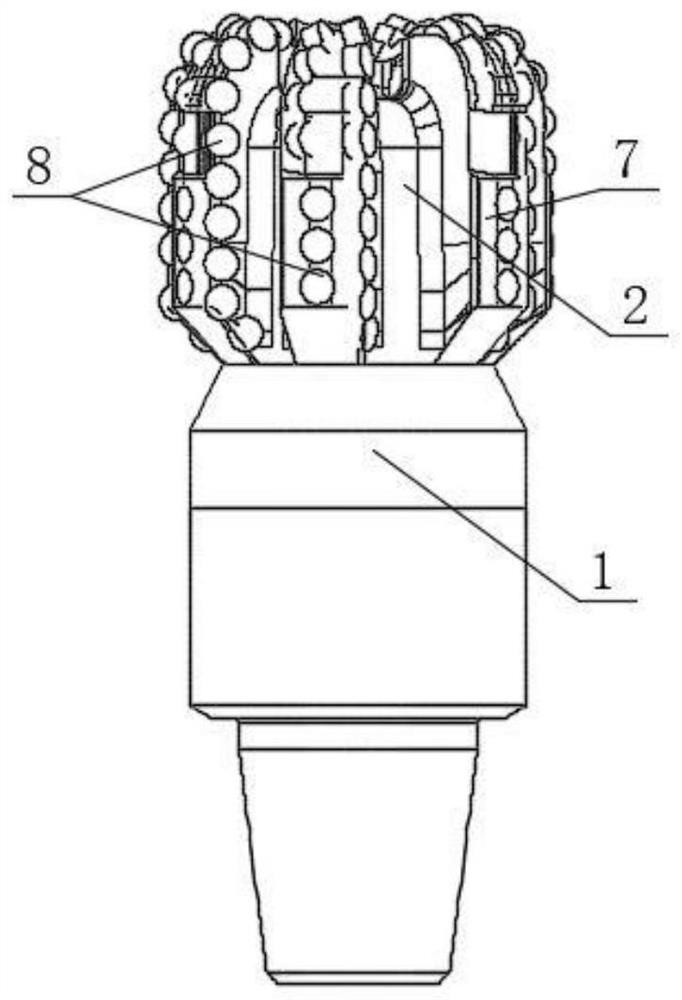

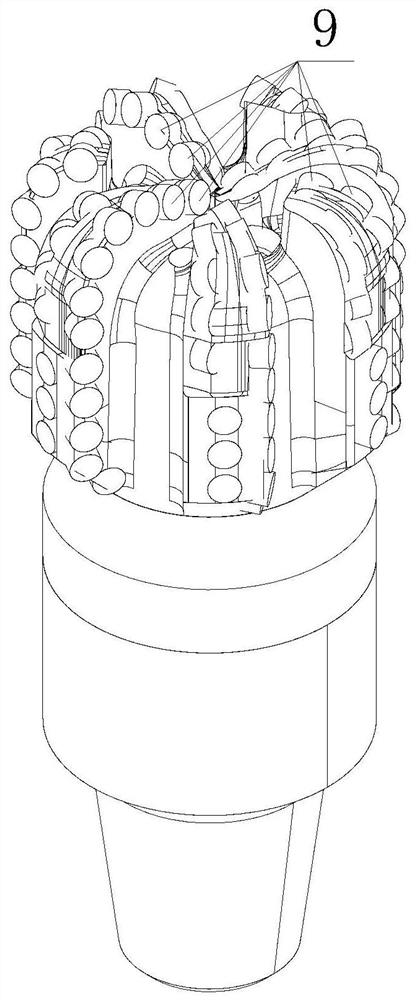

[0031] Please also refer to the attached figure 1 - attached Figure 4 , this embodiment provides a special rotary steerable drill bit for superhard formations. The special rotary steerable drill bit for superhard formations is mainly used to solve the problem of untimely heat dissipation during the high-speed use of the drill bit in the prior art and poor drilling effect when facing superhard formations. To solve the problem, the special rotary steerable drill bit for superhard formation is already in the stage of practical use.

[0032] This application is carried out through the following examples. The special drill bit for superhard formation rotary steering includes a connecting body 1, a working body 2 and a cutting assembly. The working body 2 is fixedly connected to the upper end of the connecting body 1. The cutting assembly is fixedly connected to the working body 2; cutting The assembly includes a cutting block group and 8 groups of cutting teeth, the cutting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com