Oil smoke extraction cover with intelligent air extraction adjustment function

A fume hood and fume hood technology, which is applied in the field of fume hoods, can solve the problems that the fan blades are easy to accumulate oil, cannot automatically adjust the exhaust efficiency, and affect the fan blade exhaust efficiency, etc., and achieve the effect of improving the exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

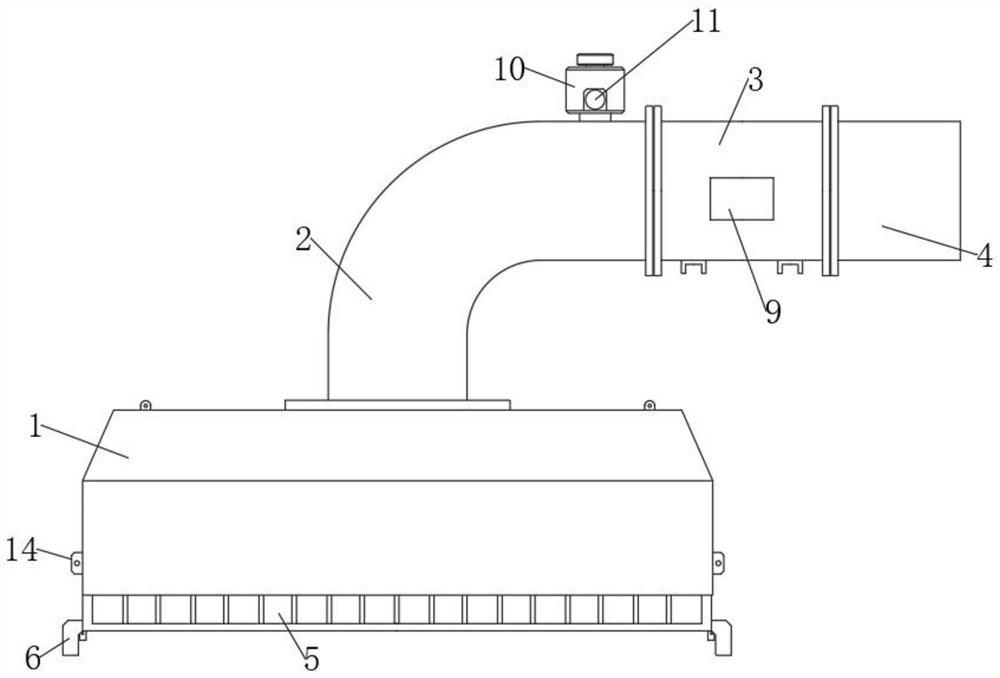

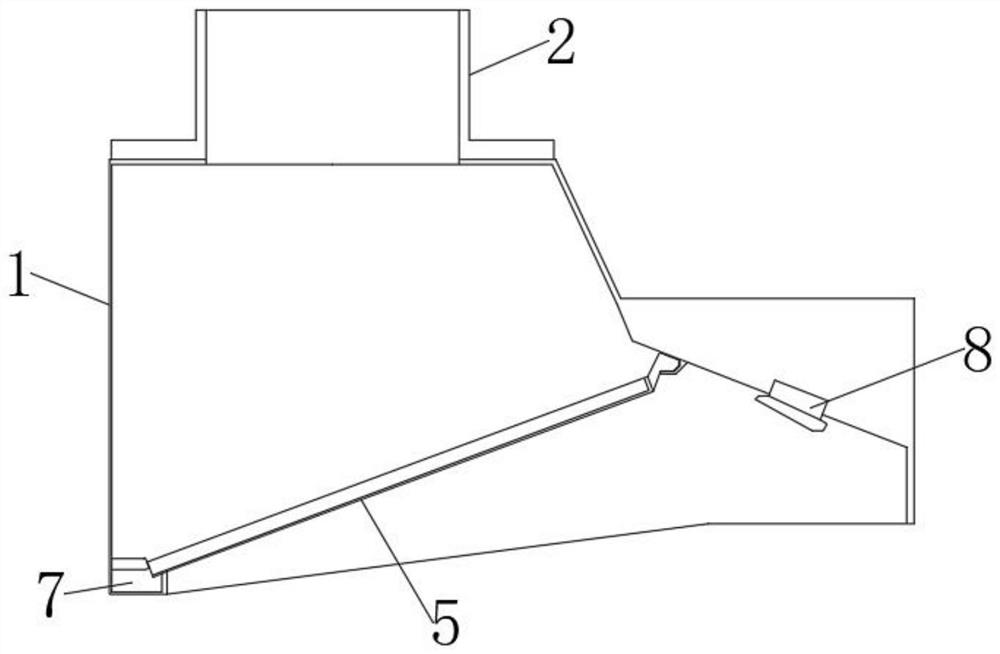

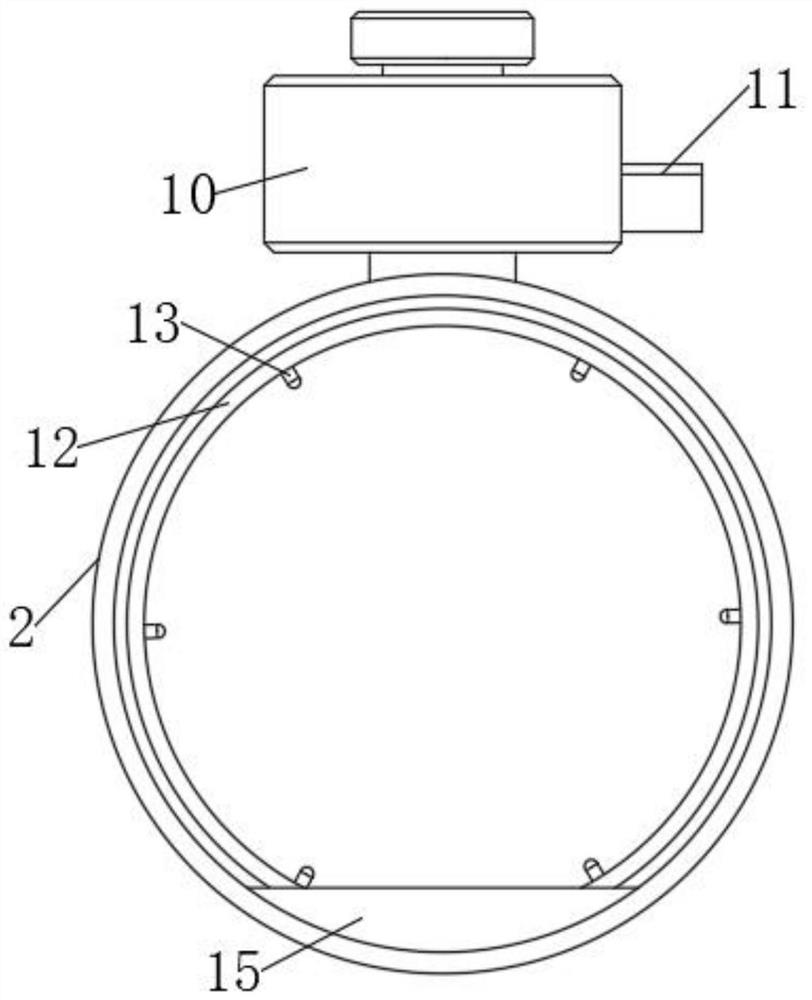

[0025] Such as Figure 1-Figure 4 As shown, a range fume hood with intelligent ventilation adjustment includes a range fume hood 1, an elbow 2 and a degreaser tank 10, the upper center of the range fume hood 1 is connected with an elbow 2 by bolts, and the center of the upper end of the elbow 2 is connected by a screw There is a degreasing agent tank 10, and one side of the degreasing agent tank 10 is connected with an atomizing pump 11 by bolts, and a spray ring pipe 12 is welded inside the upper end of the elbow 2, and atomizing nozzles 13 are arranged at equal intervals on the spray ring pipe 12. A baffle plate 15 is welded on the inner bottom of the upper end of the head 2, a fume concentration sensor 8 is installed on the inner upper part of the fume hood 1, and the end of the elbow 2 far away from the fume hood 1 is connected with an axial flow fan 3 through a flange, and the outer side of the axial flow fan 3 is connected by screws With the intelligent control module 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com