Dual-mode QFP and SOP packaging component pin coplanarity detection system

A technology for testing systems and components, applied to instruments, measuring devices, electrical devices, etc., to achieve good promotion and reduce virtual soldering effects

Pending Publication Date: 2022-04-12

LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The system of the invention can solve the problem of screening a large number of components that do not conform to coplanarity before welding components in the SMT production line, and effectively eliminate unqualified components

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

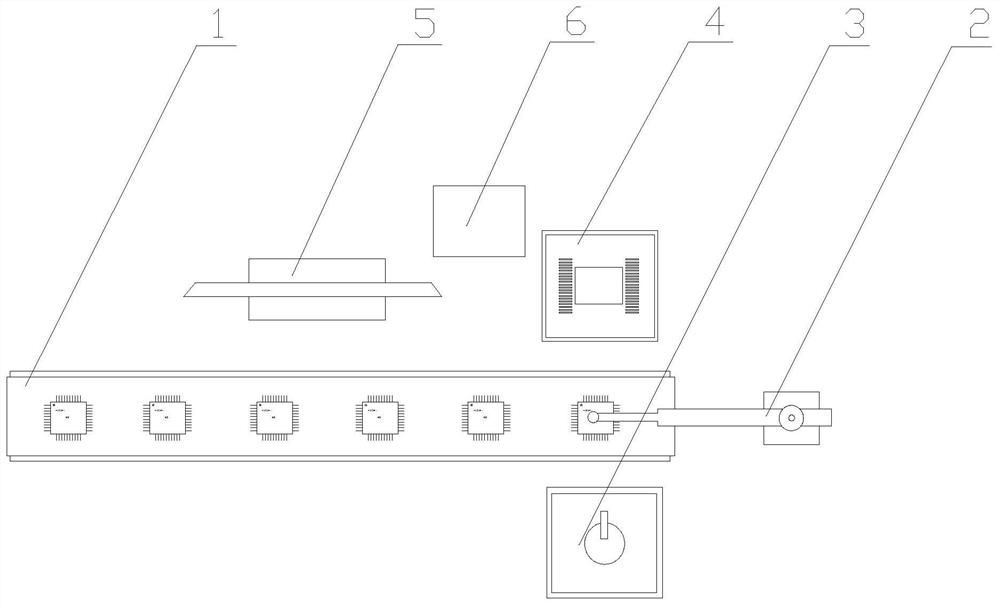

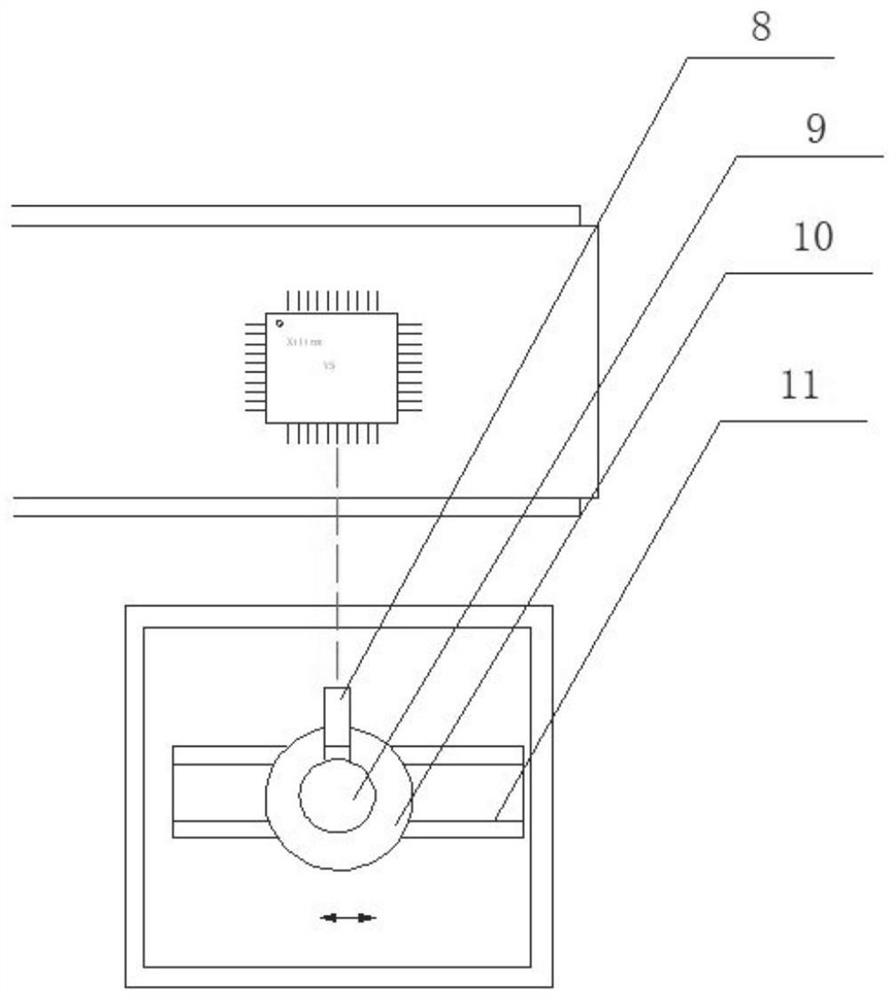

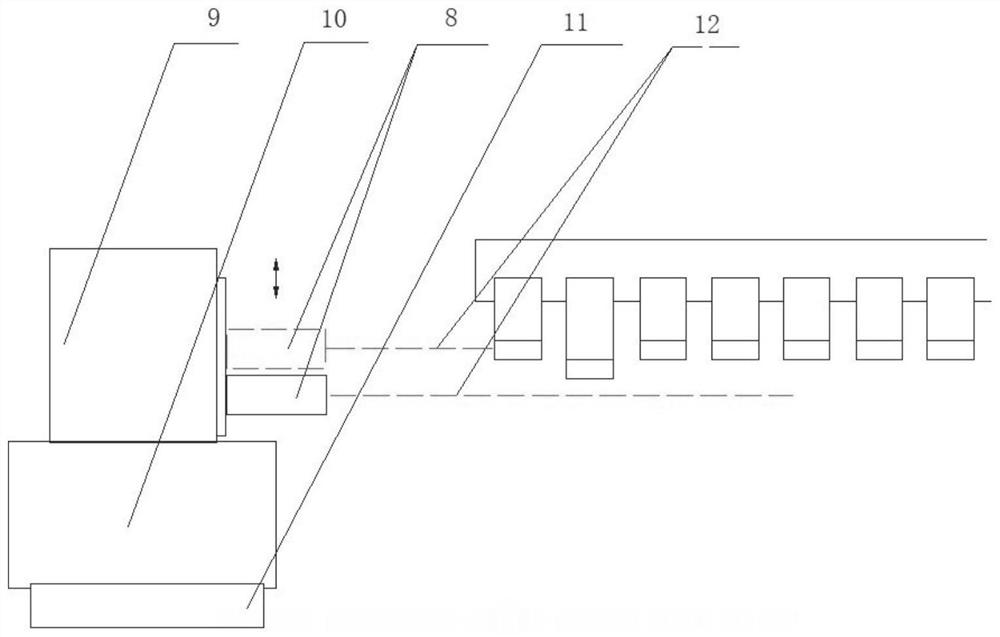

[0045] The system of this embodiment includes a component conveyor belt, a component pick-and-place device, a non-contact measurement device for coplanarity of laser components, a contact measurement device for resistance coplanarity, a video display, and a main controller.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a dual-mode QFP and SOP packaging component pin coplanarity detection system which comprises a component conveying device, a component taking and placing device, a laser component coplanarity non-contact measuring device, a resistance coplanarity contact measuring device, a video display and a main controller. The component conveying device conveys a QFP or SOP packaging component to a designated position, and the component taking and placing device picks up the component and then places the component at a designated measurement position; the laser component coplanarity non-contact measurement device carries out laser non-contact measurement on a component and measures whether a component pin has a non-coplanarity problem or not. The resistance coplanarity contact type measuring device measures the rising displacement of the resistance value contactor, and when the rising displacement of the resistance value contactor exceeds a specified size, automatic voice alarm is carried out. According to the system, the problem of screening of a large number of components which do not conform to coplanarity before components are welded on the SMT production line can be solved, and unqualified components are effectively removed.

Description

technical field [0001] The invention belongs to the technical field of electronic component measurement, and in particular relates to a component pin coplanarity detection system. Background technique [0002] In the existing secondary screening test of airborne product components, the appearance inspection of surface mount components is usually carried out in accordance with GJB7243, GJB548B and other standards, and the inspection effect is only carried out around the appearance defects and character integrity of components. However, the coplanarity index of surface-mounted components (such as QFP packaged components) cannot be effectively detected and judged, resulting in QFP packaged components that cannot be normally processed on the subsequent SMT production line due to poor coplanarity. Automatic soldering greatly affects the efficiency of circuit board production, especially the QFP package type components that come off the SMT production line in the later stage due t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/00G01B11/02G01B7/00G01B7/02

Inventor 刘旭峰梁树茂万翔

Owner LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com