Half-mold blowing lift-augmentation wind tunnel test method and test device for transporter

A technology for wind tunnel testing and transport aircraft, applied in the field of wind tunnel testing, can solve problems such as the accuracy and precision need to be improved, the flow field around the wing is complex, and it cannot meet the needs of model pre-research and development, and achieves precise and improved testing. Verify the evaluation ability and the effect of convenient layout

Active Publication Date: 2022-04-12

LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

View PDF12 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006]

When the high-pressure air flow acts on the surface flow field of the wing in the flap blowing air-lifting technology, the flow field around the wing becomes very complicated. At present, it is difficult to use calculation methods to give accurate results. It is mainly determined

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

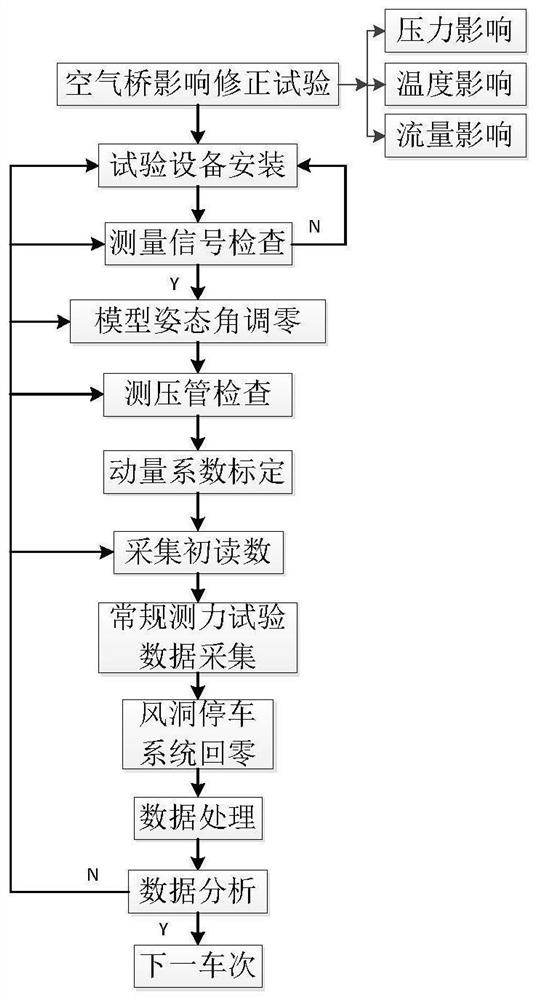

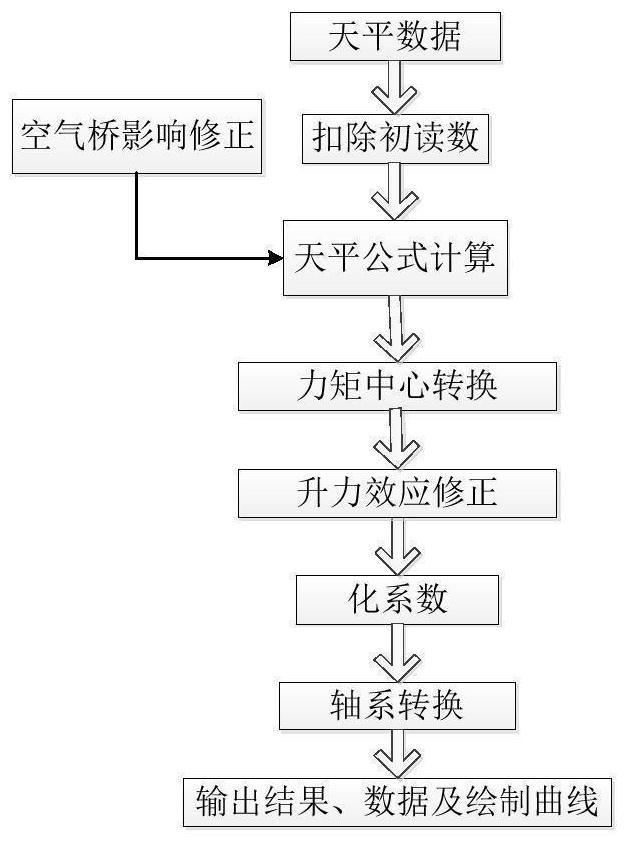

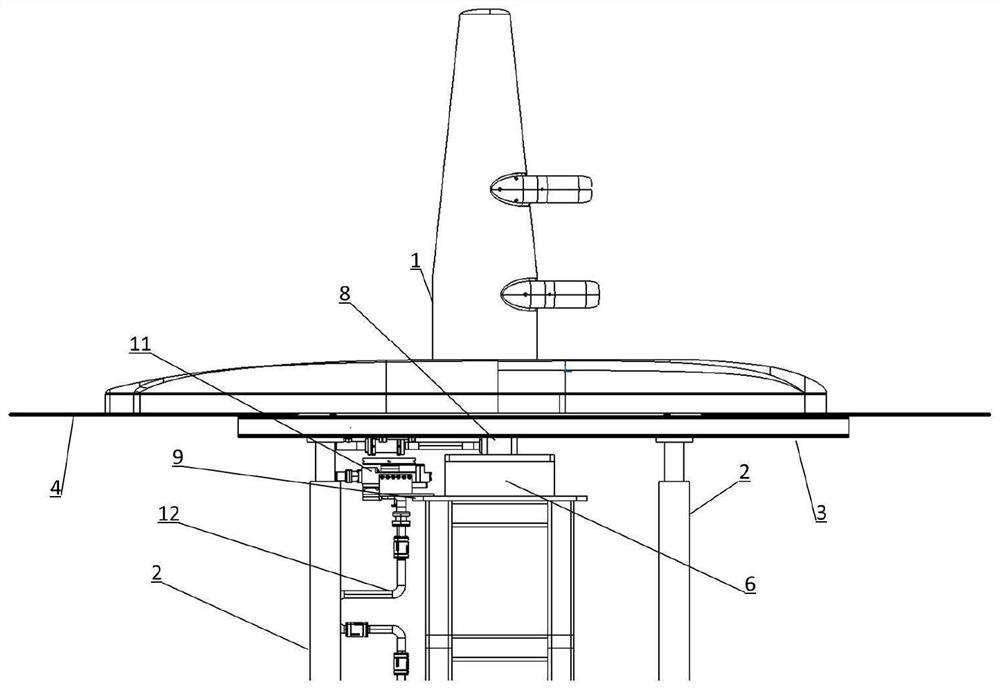

The invention discloses a transport plane half-mold blowing high lift wind tunnel test method and a test device. The test method comprises the following steps: step a, calibrating the influence of high-pressure air on balance load after passing through an air bridge; b, installing a test device and a test model, and adjusting the attitude angle of the test model to a zero point; c, calibrating a momentum coefficient; d, adjusting the attitude angle of the test model to a zero point, and collecting an initial reading; e, adjusting the wind speed to a test wind speed, and adjusting the blowing capacity coefficient to a test state; f, adjusting the attitude angle of the test model, and recording a balance signal, an attitude angle signal, a pressure sensor signal and a temperature sensor signal; step g, processing balance data; and step h, analyzing balance data. By the adoption of the half-mold blowing lift-augmentation wind tunnel test method and device for the transport plane, the precision of blowing parameter control and aerodynamic force measurement is improved; and reliable wind tunnel test data is provided for the evaluation of the air blowing lift augmentation aerodynamic performance of transportation aircrafts.

Description

technical field [0001] The invention relates to a method for testing a half-model of a transport aircraft in a wind tunnel for blowing air to increase lift, and belongs to the technical field of wind tunnel testing. Background technique [0002] The wings of modern transport aircraft are often equipped with movable parts such as front and rear edge flaps and slats. By controlling the deflection of these moving parts, the shape of the wing surface can be changed within a certain range, affecting the airflow direction on the upper and lower surfaces of the wing, thereby increasing the lift of the wing and improving the take-off and landing performance of the aircraft. The slots between active control surfaces such as slats and flaps make the flow field very complex, including boundary transition, flow separation, mutual interference of wake flow, etc. These complex flow phenomena affect the flow quality on the airfoil , Bringing a series of problems such as excessive noise an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M9/02G01M9/04

CPCY02T90/00

Inventor 王万波张鑫巍然唐坤黄勇

Owner LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com