Optical film backlight composition structure

An optical film and backlight technology, applied in the field of optical film backlight composition structure, can solve the problems of reduced service life, weak light source intensity, easy heat generation, etc., and achieve the effects of improving service life, improving heat transfer speed, and strengthening light source intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

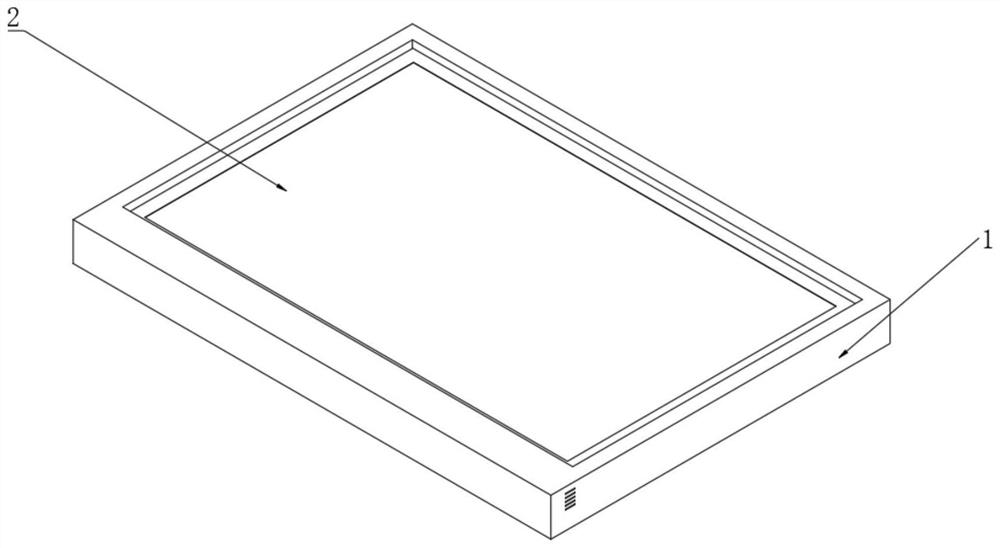

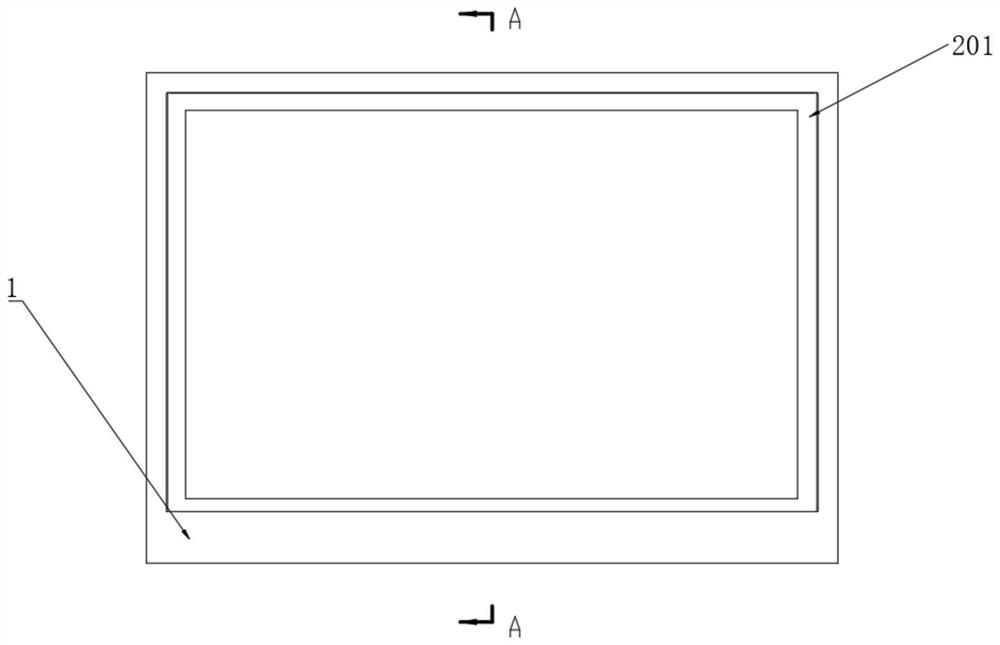

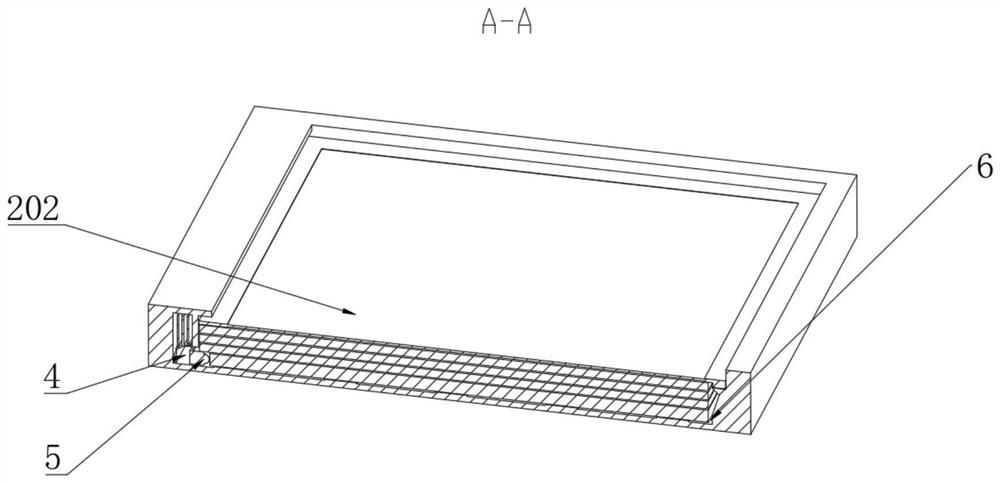

[0035] like Figures 1 to 10 As shown, an optical film backlight composition structure includes a base 1, a combination groove 6 is opened inside the base 1, a back plate is integrally arranged at the bottom of the combination groove 6, and an optical film group is arranged on the upper surface of the back plate through a first tape ring 7. 2. The LED mounting seat 10 is fixedly installed on the upper side of the backboard, and the base 1 above the LED mounting seat 10 is integrally provided with a T-shaped baffle 12. The optical film group 2 includes a reflective film layer 207 and a light guide plate layer 206 , the reflective film layer 207 is connected to the backboard through the first tape ring 7, the first tape rings 7 are respectively arranged on the upper surface of the backboard, and the LED lamp 5 is electrically installed between the LED mounting seats 10, and the LED lamp 5 is located on the reflective film layer 207 below and one side are attached to each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com