Triangle optical cable

An optical cable and triangular technology, applied in the field of triangular optical cables, can solve problems such as failure to work normally, poor directional impact resistance of optical cables, damage to optical cables, etc., and achieve the effects of high laying stability, high structural stability, and not easy to dislocate and deform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

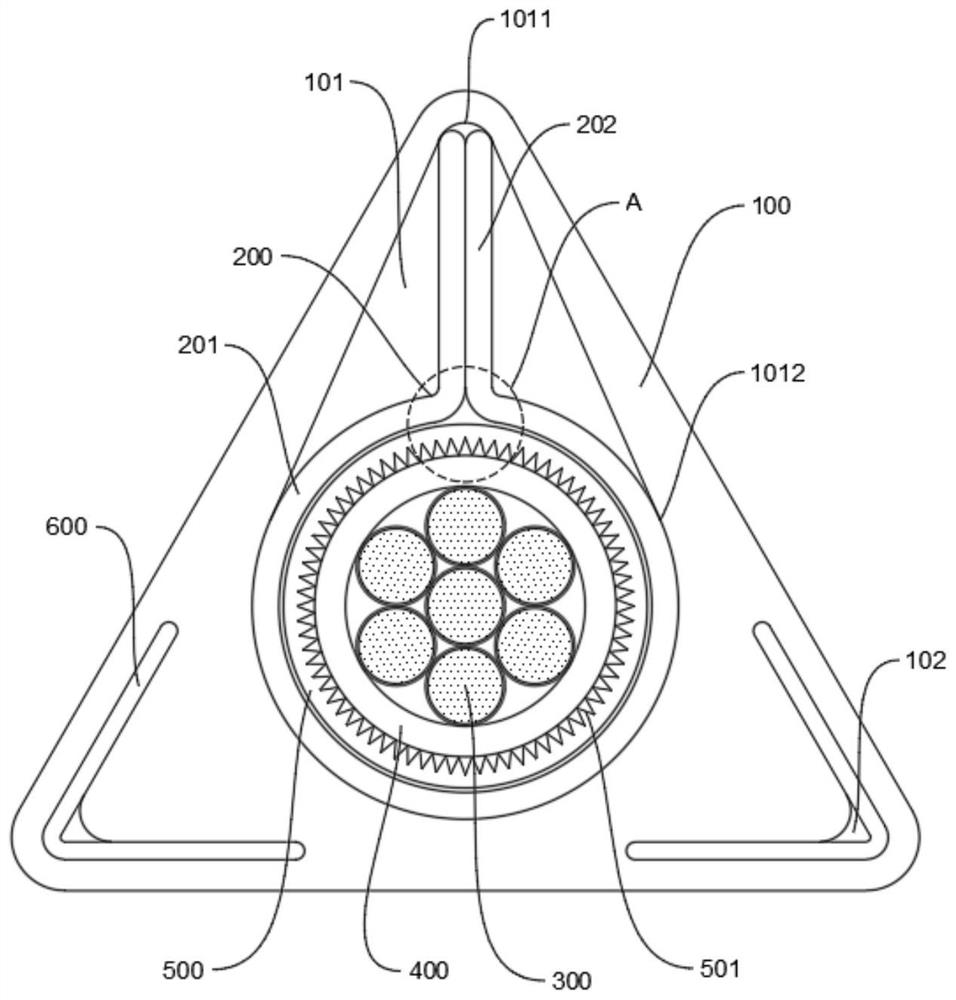

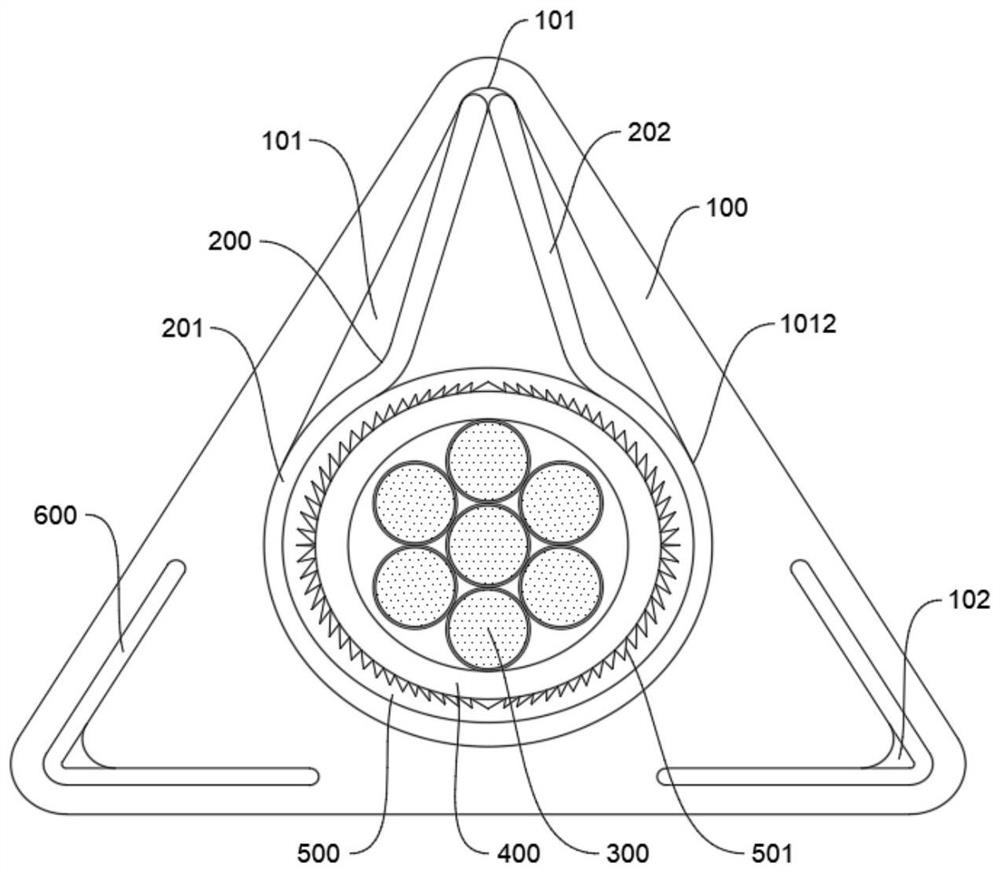

[0045] a kind of like figure 1 The triangular optical cable shown specifically includes:

[0046] The sheath 100, reinforcement cladding 200 and core wires arranged in sequence from outside to inside;

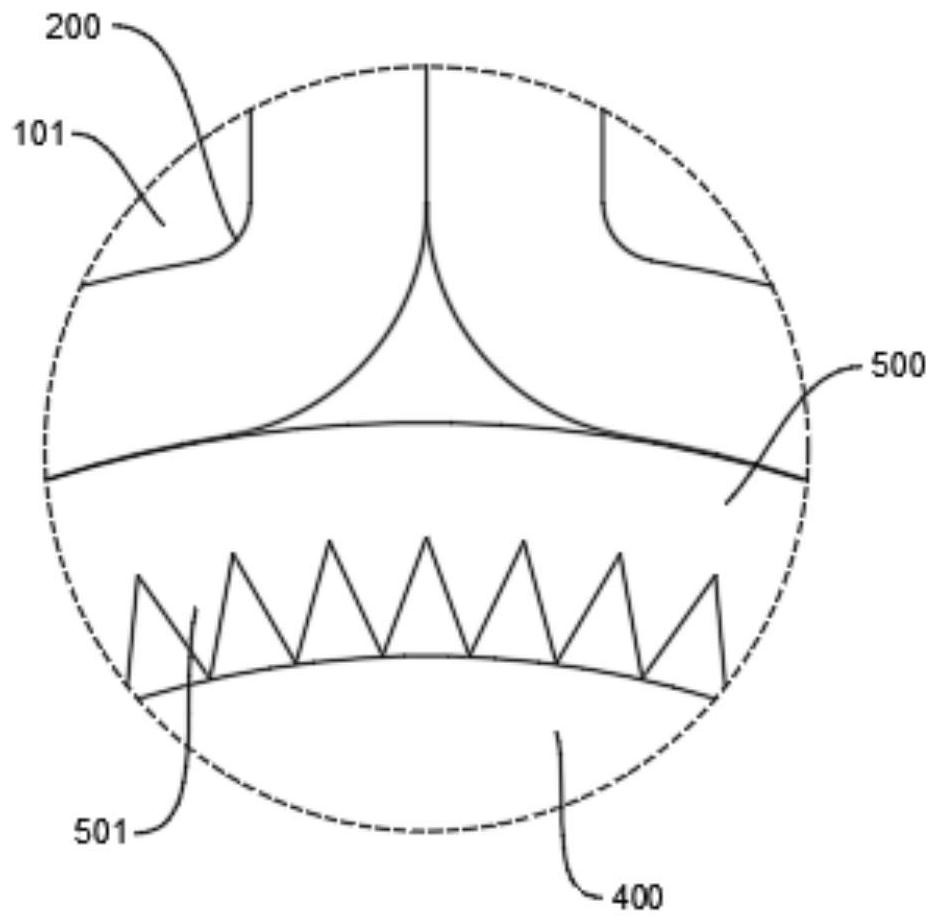

[0047] The sheath 100 is a triangular special-shaped sheath, and a drop-shaped cavity 101 is provided in the sheath 100. The tip of the drop-shaped cavity 101 faces the tip of the top of the sheath 100, and the round head 1012 faces the side opposite to the tip;

[0048] The reinforcement cladding 200 is composed of a support rib 202 and an annular cladding 201. The annular cladding 201 is arranged on the round head 1012 of the drop-shaped cavity 101 and is against the inner wall of the round head 1012 of the drop-shaped cavity 101. connected, and it is provided with an opening toward the tip 1011 of the drop-shaped cavity 101, and both ends of the opening extend toward the tip 1011 of the drop-shaped cavity 101 to form support ribs 202, and the two support ribs 202 are formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com