Channel flow measurement method based on scale effect of central cylindrical rectangular groove

A technology of central cylinder and scale effect, applied in the field of channel flow measurement method, can solve the problems that can not be measured by channel flow, cannot be used to predict the flow of the central cylindrical rectangular slot, and the flow prediction method of the central cylindrical rectangular slot, etc. Water utilization efficiency, improving numerical calculation accuracy and calculation efficiency, and avoiding the effect of backwater waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

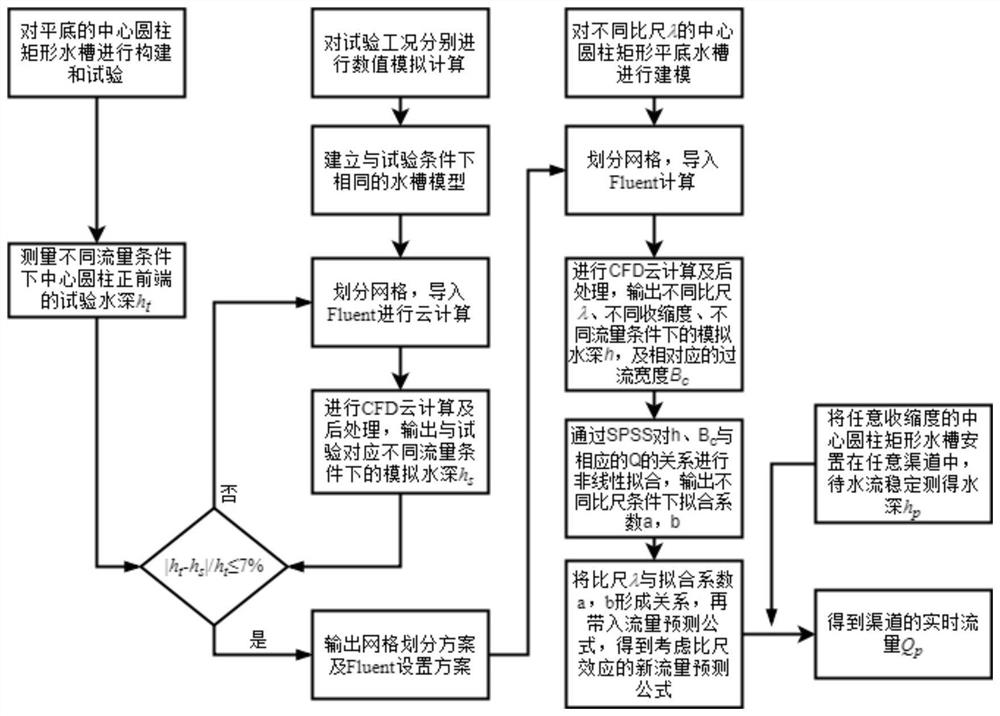

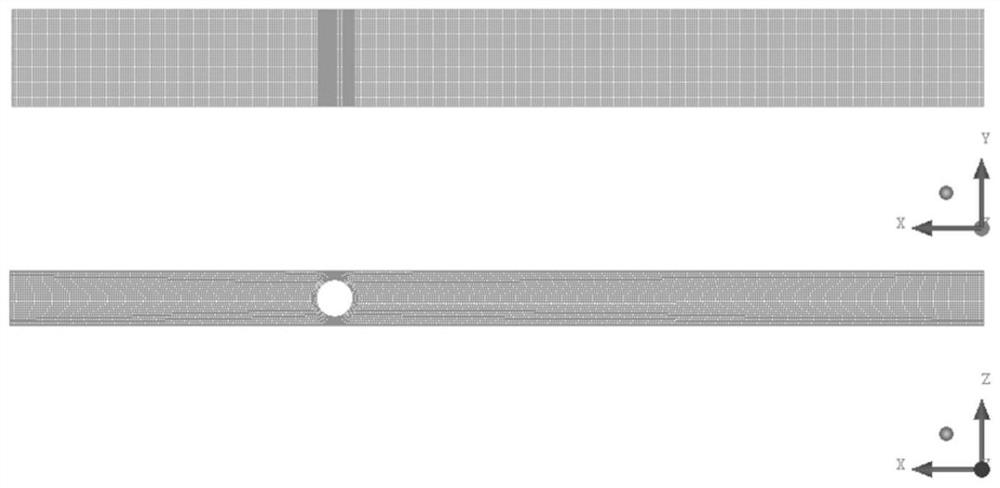

[0040] The flow chart of the channel flow measurement method based on the scale effect of the central cylindrical rectangular groove in this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0041] Step 1: Establish a physical test model of the central cylindrical rectangular groove and conduct a physical model test. When the water flow is stable, collect the height of the submerged water depth of the front end of the cylinder;

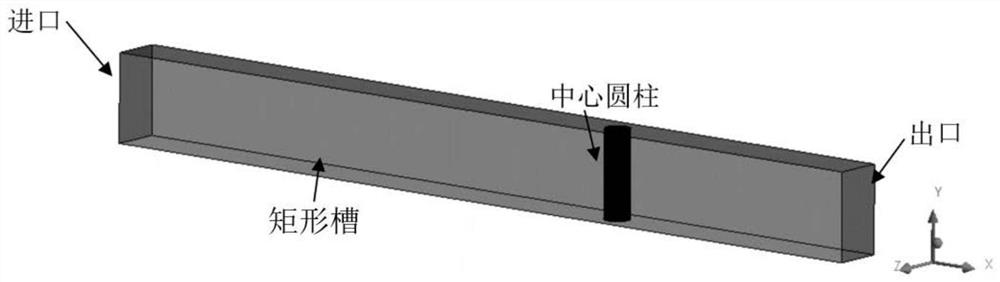

[0042] In the physical model, the material of the central cylindrical rectangular trough model is transparent plexiglass, the bottom of the rectangular trough is placed horizontally, the flow section of the rectangular trough is rectangular, the bottom width is 17cm, the height is 30cm, and the diameter of the central cylinder is 11.4cm. The shrinkage ratio was 0.670.

[0043] The length of the rectangular tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com