Nuclear power equipment pipeline inspection device

An inspection device and pipeline technology, which is applied in the inspection field, can solve problems such as inconvenient operation, narrow pipeline space, and low inspection efficiency, and achieve the effects of convenient operation, good imaging effect, and high inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

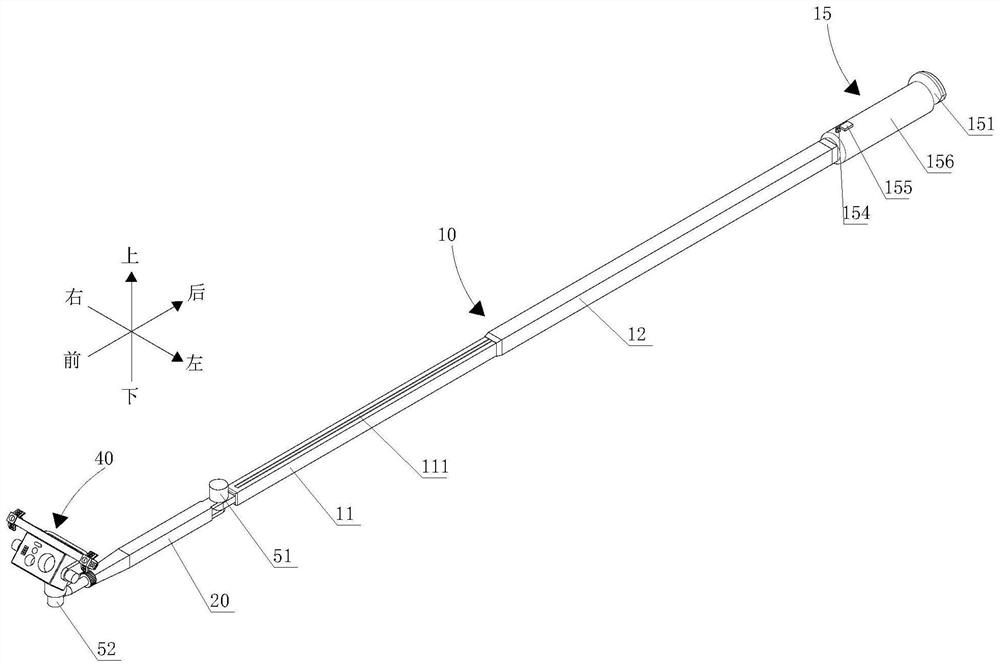

[0032] The up-down, left-right, front-back directions described in the present invention are figure 1 up and down, left and right, and front and back directions.

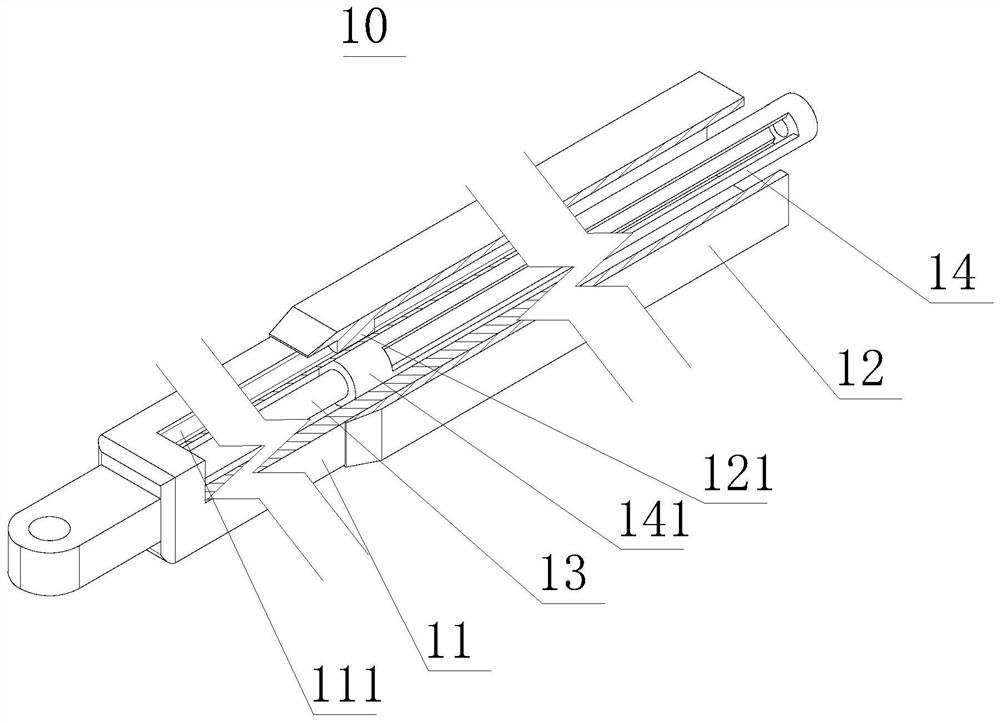

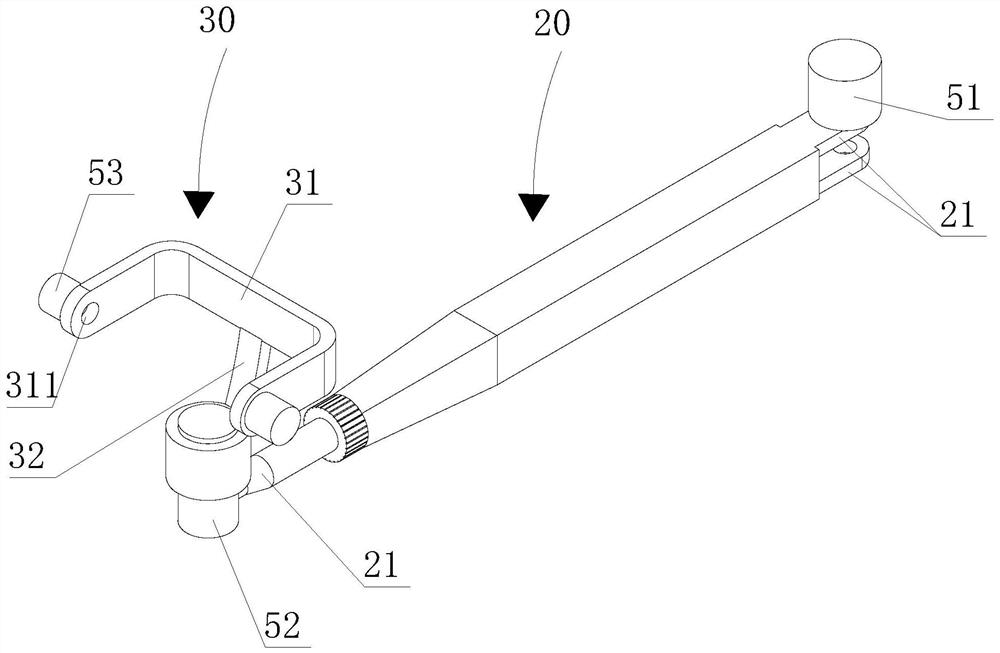

[0033] Such as Figure 1-6 As shown, the nuclear power equipment pipeline inspection device provided by the present invention includes: a telescopic rod 10, a steering rod 20, a pan platform 30, and a lens module 40, wherein the telescopic rod 10 can expand and contract along its own axial direction, and the steering rod 20 Rotationally connected to the front end of the telescopic rod 10, the pan platform 30 is rotatably connected to the front end of the steering rod 20, and the lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com