Oxide semiconductor film and semiconductor device

An oxide semiconductor and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, gaseous chemical plating, etc., can solve the problems of high insulation of alumina and difficulty in obtaining mixed crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

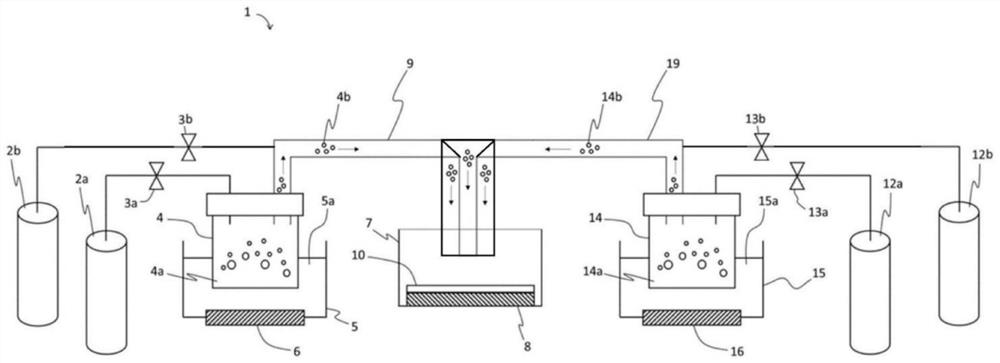

[0072] 1. Membrane making device

[0073] use figure 1 , illustrating the atomization CVD (Mist Chemical Vapor Deposition, atomization chemical vapor deposition) device (1) used in this embodiment. The atomizing CVD device (1) at least includes: a carrier gas source (2a, 12a) for supplying carrier gas, and a flow regulating valve (3a, 13a) for adjusting the flow rate of the carrier gas sent from the carrier gas source (2a, 12a) , an atomization source (4, 14) containing a raw material solution (4a, 14a), a container (5, 15) containing water (5a, 15a), an ultrasonic vibrator installed on the bottom surface of the container (5, 15) (6, 16), film forming chamber (7), supply pipes (9, 19) connecting the atomization generation source (4, 14) to the vicinity of the substrate (10), and a hot plate arranged in the film forming chamber (7) (8). Furthermore, a substrate (10) is arranged on the hot plate (8). In addition, there are two kinds of raw material solutions (4a, 14a), respe...

Embodiment 2

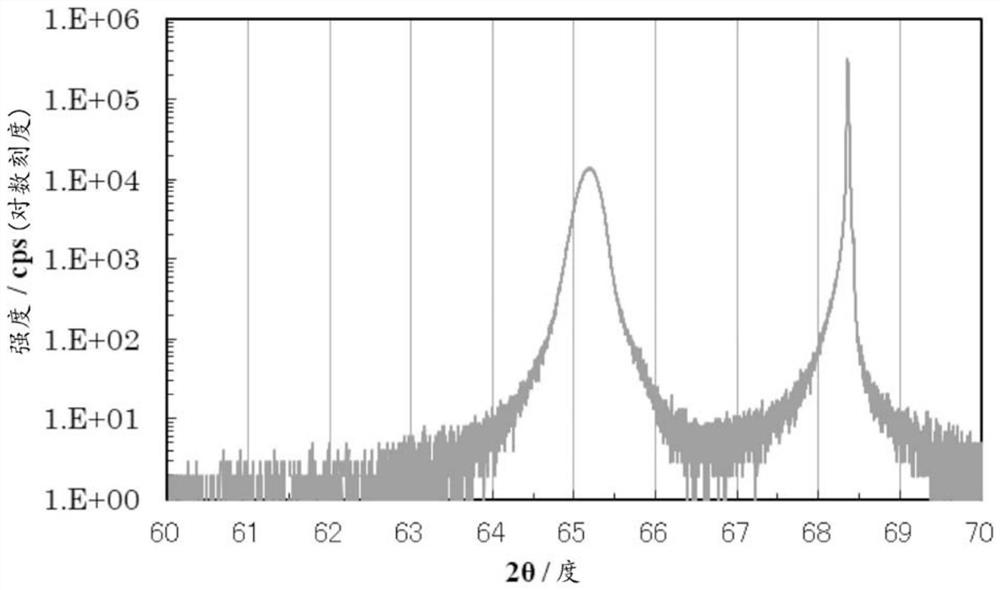

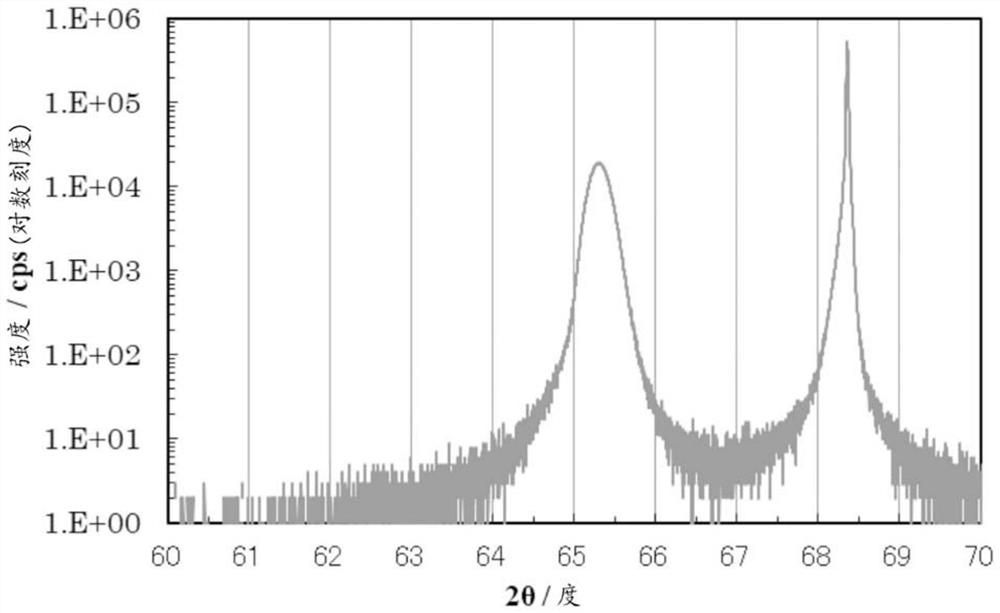

[0082] Film formation was performed in the same manner as in Example 1, except that the flow rate of the first carrier gas was 0.5 L / min and the film formation time was 3 hours. The film thickness of the obtained film was 1310 nm. As a result of film identification using an X-ray diffraction apparatus for the obtained film, the obtained film has a corundum structure (Al 0.15 Ga 0.85 ) 2 o 3 membrane. image 3 The measurement results of XRD are shown. For the obtained α-(Al 0.15 Ga 0.85 ) 2 o 3The electrical properties of the membrane are the same as in Example 1, the carrier type is n-type, and the carrier density and mobility are the same as in Example 1. The obtained film had a bandgap of 5.5 eV. In addition, the bandgap is calculated from the peaks of elastically scattered (zero energy loss) electrons and inelastically scattered (only partial loss of energy for interband transitions) electrons using reflection electron energy loss spectroscopy (REELS) . In addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap