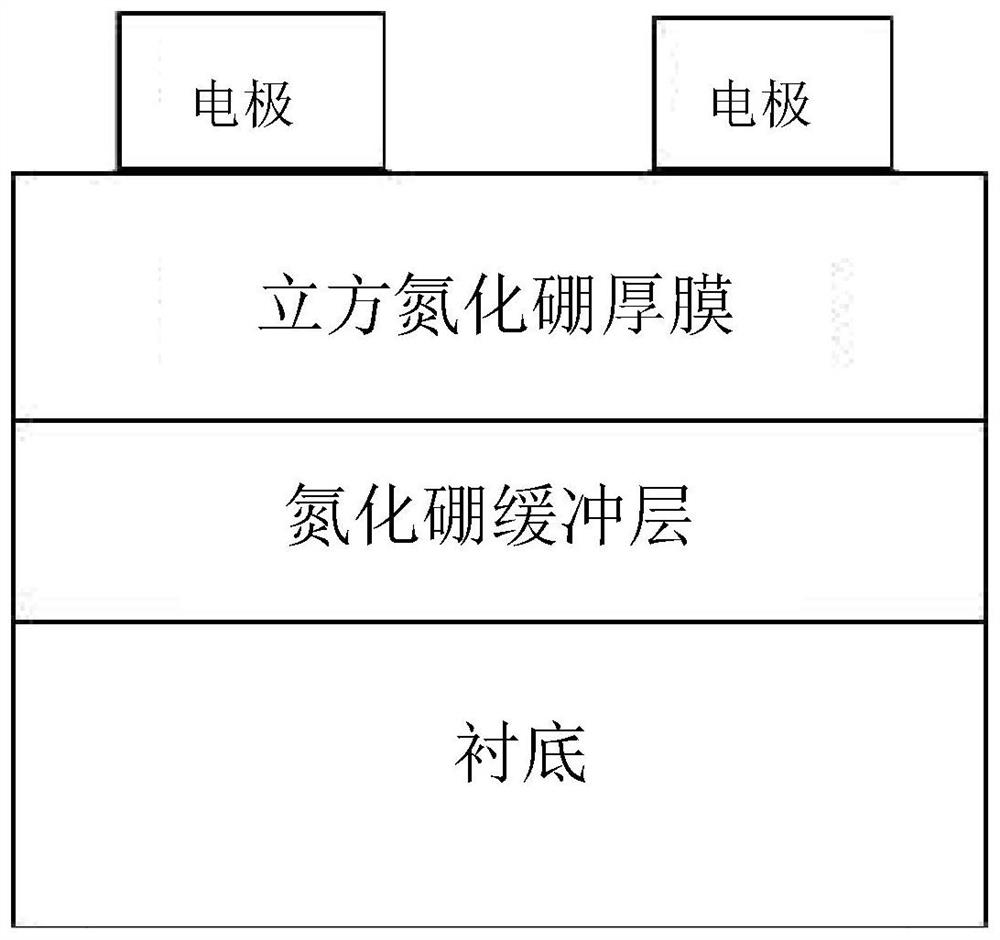

MSM type deep ultraviolet photoelectric detector based on cubic boron nitride thick film and preparation method

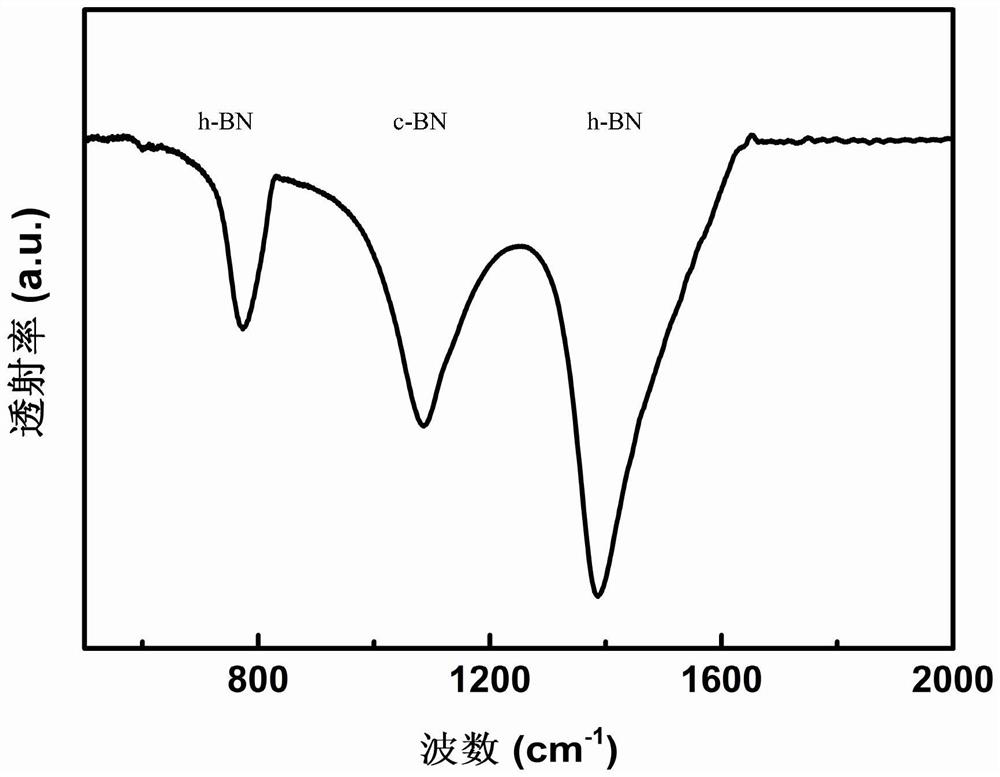

A technology of boron nitride thick film and deep ultraviolet light, which is applied in the field of semiconductor photoelectric detection, can solve the problems of poor stability of thick film, weakened cubic phase performance, and poor crystal quality, so as to facilitate device integration and facilitate large-scale Effects of scale industrialization and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

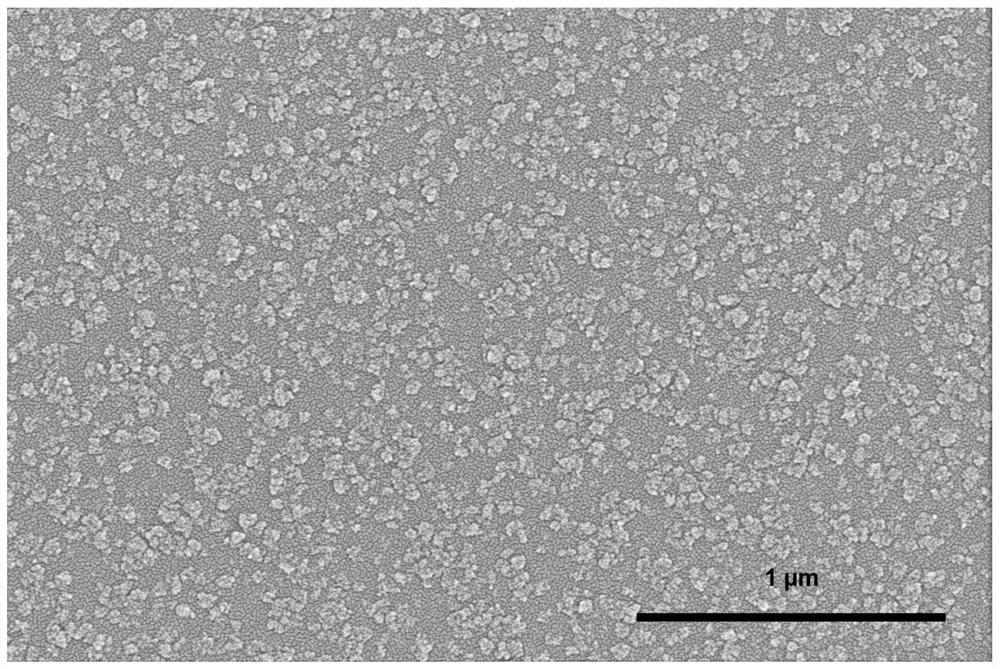

[0037] Preferably, the substrate is an n-type (100) silicon substrate with a thickness of 300 nm. The cut silicon wafers were ultrasonically cleaned in acetone, ethanol, and deionized water, then soaked in HF solution to remove surface oxides, dried with nitrogen and placed on the sample holder. The sample holder is sent into the magnetron sputtering chamber, and then vacuumized, when the vacuum reaches 10 -5 pa, heat the substrate to 600°C and continue to evacuate the chamber until it reaches 10 -5 Pa, the working gas nitrogen and argon are introduced into each 50sccm, and the working pressure is 2pa; the distance between the substrate and the target is 8cm; the negative bias voltage is 100V; the power of the radio frequency source is 120W; after pre-sputtering for 3 minutes, deposition for half an hour to obtain nitriding The boron buffer layer is then deposited for 2.5 hours to obtain a thick film of cubic boron nitride. Finally, electrodes were prepared on the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com