Diamond-like carbon protective film and preparation method thereof

A protective film and diamond technology, which is applied in the manufacture of microstructure devices, metal material coating technology, gaseous chemical plating, etc., can solve problems such as system failure, large thickness, and increased system size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

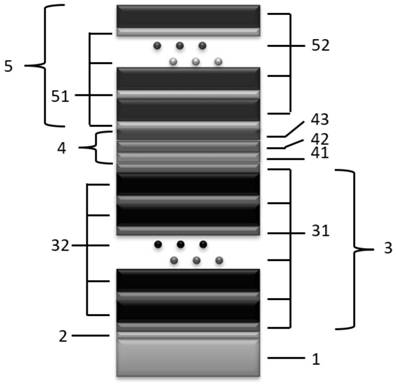

[0042] A diamond-like protective film, which sequentially includes a micro-nano electronic device substrate, a metal layer I, an insulating layer belt, an internal stress buffer layer and a wear-resistant layer belt from bottom to top; the insulating layer belt includes a silicon-containing thin layer and a non-doped Doped DLC layer, the bottom layer of the insulating layer is a silicon-containing thin layer, and then the non-doped DLC layer and silicon-containing thin layer are alternately distributed in turn, and the internal stress buffer layer includes H-W:DLC from bottom to top layer, M-W: DLC layer, L-W: DLC layer, the wear-resistant layer belt includes metal layer II and S-W: DLC layer, and the uppermost layer of the internal stress buffer layer is alternately distributed with metal layer II and S-W: DLC layer , the uppermost layer of the wear-resistant layer belt is a S-W:DLC layer.

[0043] The preparation method of above-mentioned diamond-like carbon protective film ...

Embodiment 2

[0056] A diamond-like protective film, which includes a micro-nano electronic device substrate, an insulating layer belt, an internal stress buffer layer and a wear-resistant layer belt from bottom to top; the insulating layer belt includes a silicon-containing thin layer and an undoped DLC layer, The bottom layer of the insulating layer belt is a silicon-containing thin layer, and then the non-doped DLC layer and the silicon-containing thin layer are alternately distributed in sequence, and the internal stress buffer layer includes H-W:DLC layer, M-W: DLC layer, L-W:DLC layer, the wear-resistant layer belt includes metal layer II and S-W:DLC layer, the uppermost layer of the internal stress buffer layer is alternately distributed with metal layer II and S-W:DLC layer, the wear-resistant The uppermost layer of the grinding belt is the S-W:DLC layer.

[0057] The preparation method of above-mentioned diamond-like carbon film comprises the steps:

[0058] S1: Select silicon mat...

Embodiment 3

[0067] A diamond-like protective film, which includes a micro-nano electronic device substrate, an insulating layer belt, an internal stress buffer layer and a wear-resistant layer belt from bottom to top; the insulating layer belt includes a silicon-containing thin layer and an undoped DLC layer, The bottom layer of the insulating layer belt is a silicon-containing thin layer, and then the non-doped DLC layer and the silicon-containing thin layer are alternately distributed in sequence, and the internal stress buffer layer includes H-W:DLC layer, M-W: DLC layer, L-W:DLC layer, the wear-resistant layer belt includes metal layer II and S-W:DLC layer, the uppermost layer of the internal stress buffer layer is alternately distributed with metal layer II and S-W:DLC layer, the wear-resistant The uppermost layer of the grinding belt is the S-W:DLC layer.

[0068] The preparation method of above-mentioned diamond-like carbon film comprises the steps:

[0069] S1: Select germanium m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com