Method for rapidly reducing biogenic amine in sauce and improving flavor of sauce

A biogenic amine and sauce technology, applied in the field of food processing, can solve the problems of difficult control, more times of inoculation and expansion of pure-bred microorganisms, increased pollution, and out-of-sync growth and metabolism, so as to reduce the content, promote the formation of flavor, and improve the flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

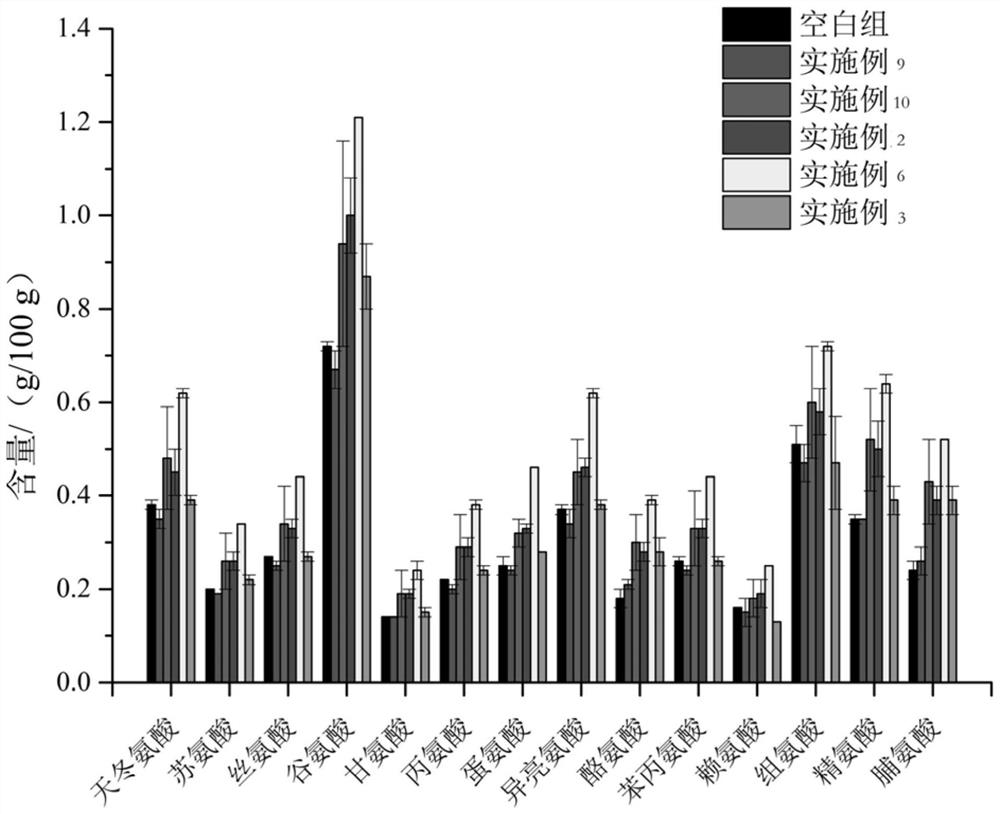

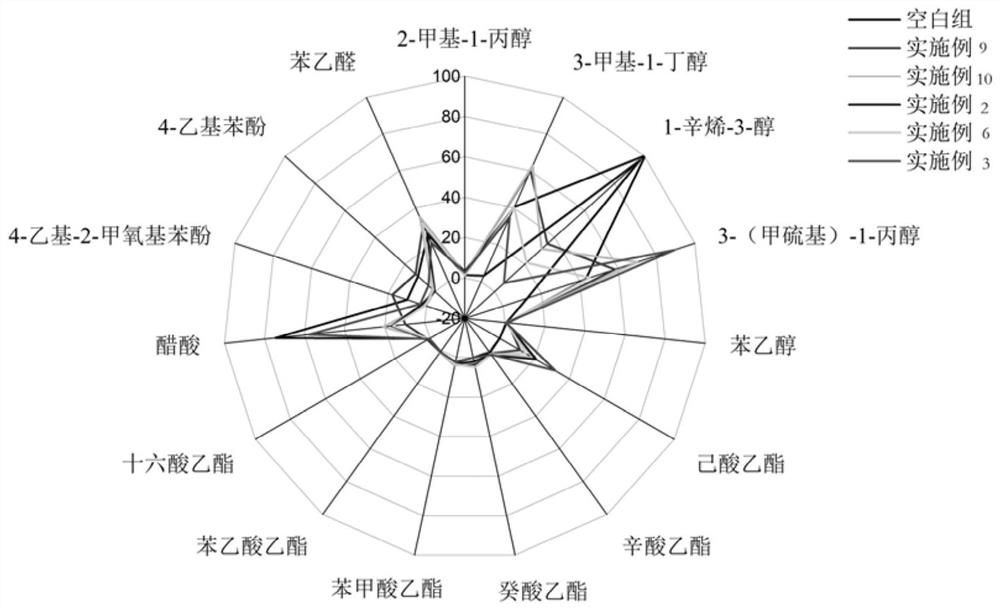

[0028] This example provides a method for quickly reducing biogenic amines in sauce and improving its flavor, which includes the following steps: prepare the first-generation soy mash with a weight ratio of 22% saline and koji at a weight ratio of 2:1, and prepare the first-generation soy sauce The mash and the bacterial liquid (Zygomyces rouckeri + Tetradococcus halophilus, the inoculation amount of Zygomyces rouckeri was 1.5wt%, and the inoculation amount of Tetradococcus halophilus was 1 wt%) were mixed and fermented for 60 days at a fermentation temperature of 32°C. Obtain the co-cultivated moromi; divide the co-cultivated moromi for the first time (this process is a round of division) and mix it with fresh moromi at an inoculation ratio of 5% and ferment at 32°C for 7 days to obtain the second-generation moromi, and then divide the second-generation moromi The mash was fermented at 32°C for 100 days to obtain the finished sauce.

[0029] Among them, the finished koji is s...

Embodiment 2

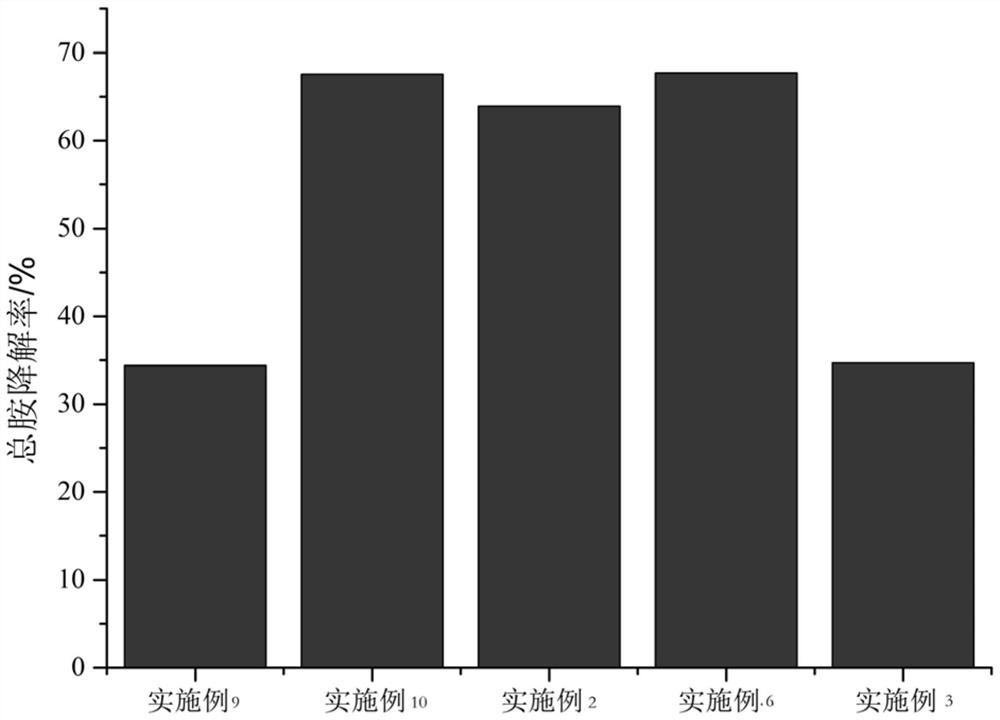

[0031] This example provides a method for quickly reducing biogenic amines in sauce and improving its flavor, which includes the following steps: preparing the first-generation soy mash with a mass percentage of 25% saline and koji at a weight ratio of 2:1, and making the first-generation sauce The mash and the bacterial liquid (Zygomyces rouckeri + Tetradococcus halophilus, the inoculation amount of Zygomyces rouckeri was 1.5wt%, and the inoculation amount of Tetradococcus halophilus was 1 wt%) were mixed and fermented for 60 days at a fermentation temperature of 30°C. Obtain the co-cultivated moromi; divide the co-cultivated moromi for the first time and mix it with fresh moromi according to the inoculation ratio of 5% and ferment it at 30°C for 7 days to obtain the second-generation moromi, and then carry out the second division (this process is two rounds of division, The inoculation ratio and operation steps are the same as those of the first division, the same below), to ...

Embodiment 3

[0034] This example provides a method for quickly reducing biogenic amines in sauce and improving its flavor, which includes the following steps: preparing the first-generation soy mash with a mass percentage of 25% saline and koji at a weight ratio of 2:1, and making the first-generation sauce The mash and the bacterial liquid (Zygomyces rouckeri + Tetradococcus halophilus, the inoculation amount of Zygomyces rouckeri was 1.5wt%, and the inoculation amount of Tetradococcus halophilus was 1 wt%) were mixed and fermented for 60 days at a fermentation temperature of 30°C. Obtain co-cultivated moromi; after the initial division of co-cultivated moromi, mix it with fresh moromi at an inoculation ratio of 5% and ferment it at 30°C for 7 days to obtain the second-generation moromi, and then carry out second division and third division (this process is three round division, the inoculation ratio and operation steps are the same as the first division, the same below), to obtain the fou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap