Bottle cap disinfection system and bottle cap disinfection method

A disinfection method and bottle cap technology, applied in the field of liquid beverage packaging, can solve the problems of difficult decomposition, human environment threat, limited microbial killing effect, etc., and achieve the effects of improving sterilization effect, reducing cost and avoiding residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

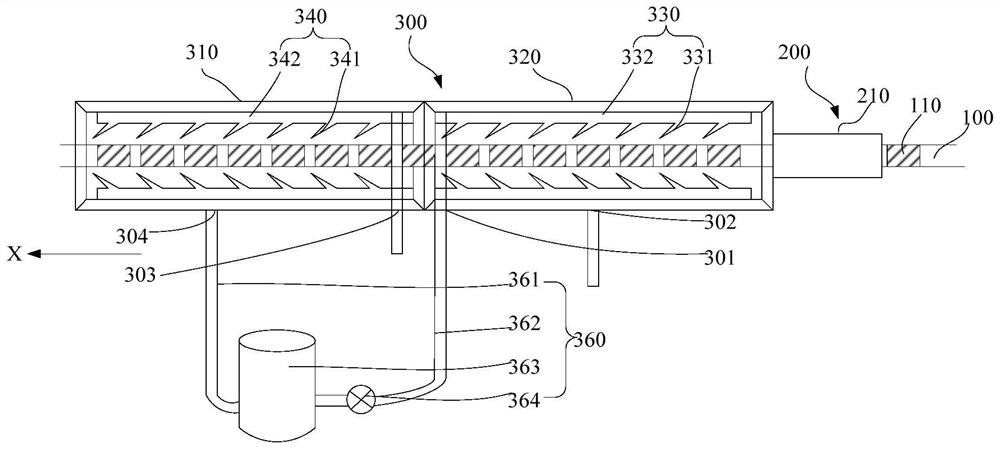

[0028] As mentioned in the background technology, current bottle cap disinfection methods usually use a single chemical disinfection method or physical disinfection method. Chemical disinfection methods are likely to cause chemical reagent residues, while physical disinfection methods do not have a good sterilization effect.

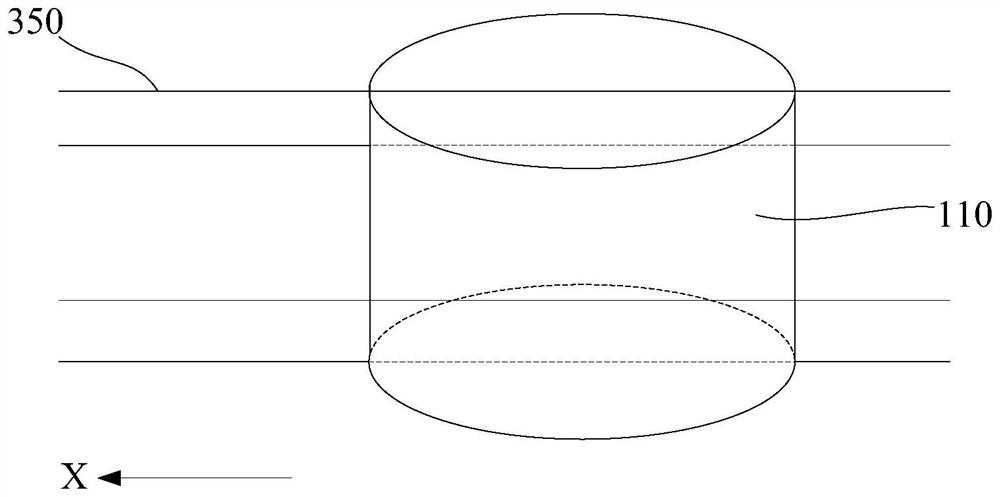

[0029] In order to solve the above problems, the embodiment of the present invention provides a bottle cap disinfection system and a bottle cap disinfection method. The physical disinfection method and the chemical disinfection method are combined. The bottle cap first enters the physical disinfection device, and then enters the chemical disinfection device after physical disinfection. The disinfection device carries out chemical disinfection. The chemical disinfection device includes a first box body and a second box body. The bottle cap is chemically sterilized for the first time in the first box body, and then enters the second box body for the second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com