Building wastewater and waste material separation treatment device

A technology of separation and treatment of waste, applied in the direction of construction waste recycling, solid waste removal, recycling technology, etc., can solve the problems of ecological environment secondary pollution resources, waste, etc., to avoid waste of water resources, avoid waste, avoid The effect of wasting water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

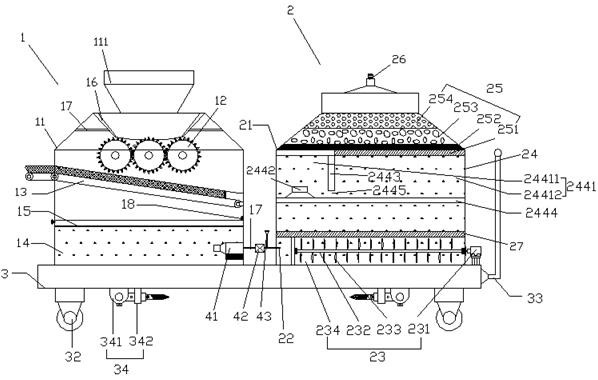

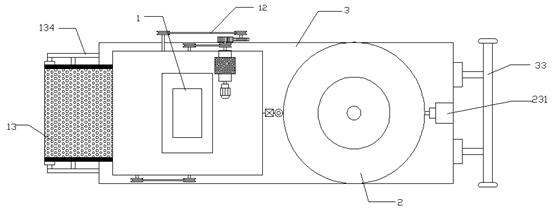

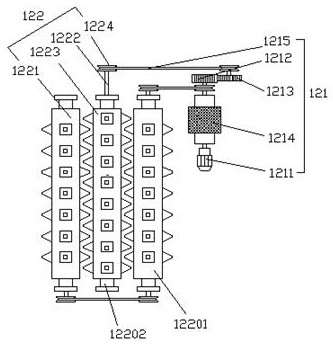

[0037] see Figure 1 to Figure 6 As shown, the application provides a construction wastewater waste separation treatment device, including: a solid-liquid separation device 1 and a sewage purification device 2, the solid-liquid separation device 1 includes a shell 11, a crushing mechanism 12 and a discharge mechanism 13, the shell 11 There is a cavity and a feed port 111 communicating with the cavity, the crushing mechanism 12 is arranged in the cavity and below the feed port 111, and the discharge mechanism 13 is partially arranged in the cavity and Located below the crushing mechanism 12 , the discharge mechanism 13 partially protrudes from the casing 11 . The sewage purification device 2 includes a housing 21 and a water purification mechanism arranged in the housing 21. The housing 21 is provided with a water inlet 22 and a water outlet 26. The water inlet 22 is connected to the housing 11 through a pipeline. The bottom is connected.

[0038] The construction wastewater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com