Thermoplastic particle material drying system

A granular material and drying system technology, which is applied in the direction of drying, drying machine, drying solid material, etc., can solve the problem of uneven drying of materials, and achieve the effect of avoiding secondary transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

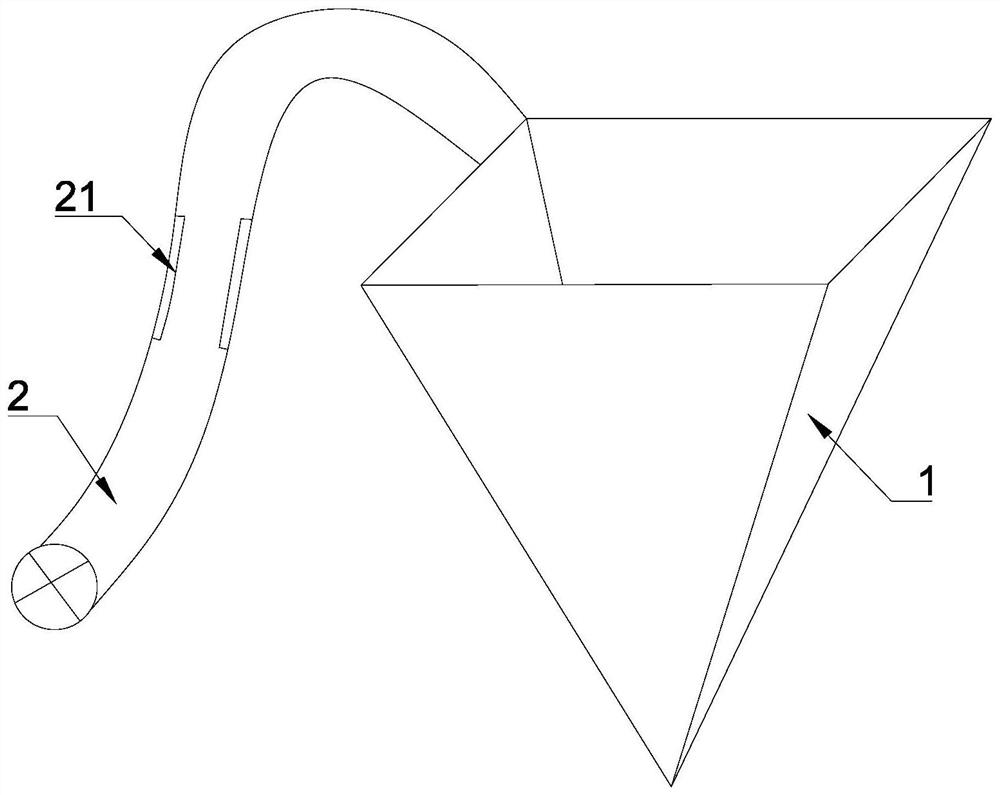

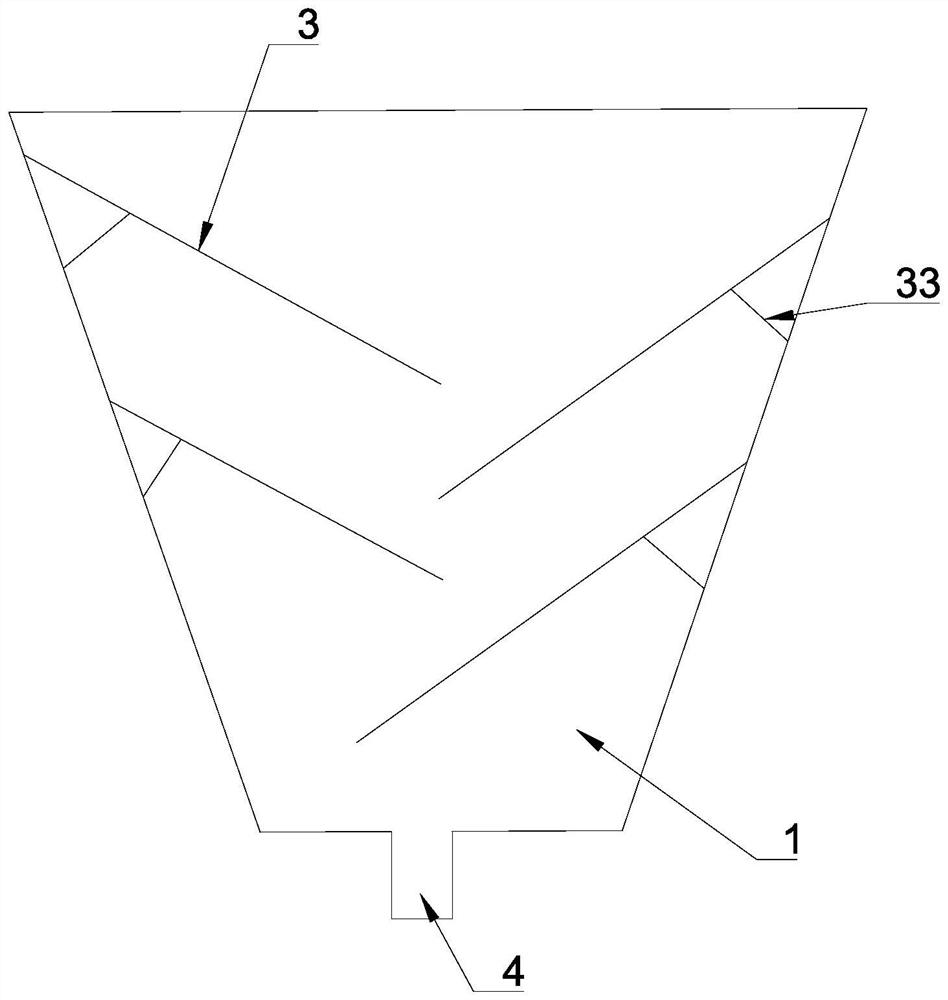

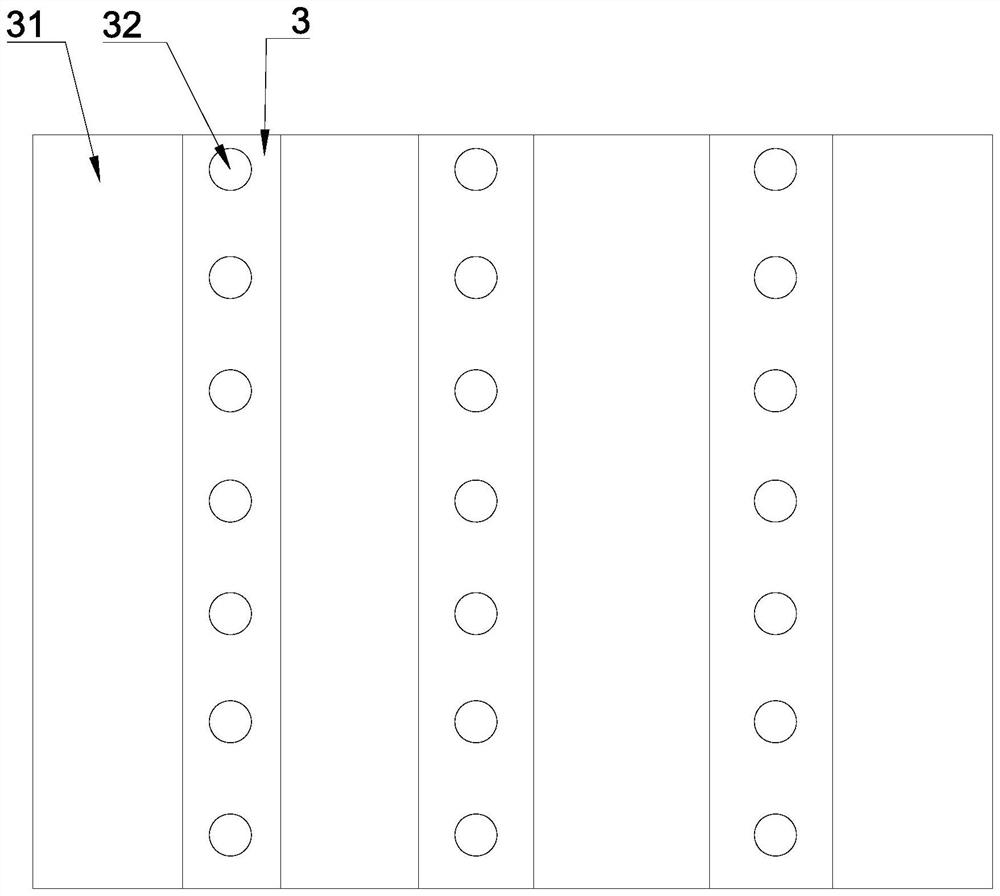

[0026] This embodiment provides a drying system for thermoplastic granular materials, including: an accommodation chamber 1 for accommodating materials, the accommodation chamber 1 is arranged in a quadrangular pyramid structure, and an air inlet 2 is arranged outside the accommodation chamber 1, and the air inlet 2 is arranged outside the accommodation chamber 1. The tuyere 2 communicates with the housing chamber 1, the side wall of the air inlet 2 is provided with a heating pipe 21, the side wall of the housing chamber 1 is provided with a number of partition plates 3, and the adjacent partition boards 3 are alternately arranged to form a material supply. The falling moving track, the bottom of the accommodation chamber 1 is provided with a discharge port 4 .

[0027] The above specific improvements are as follows: figure 1 and figure 2 As shown: most of the traditional material holding chambers 1 are circular holding chambers 1, which usually use a screen to separate the ...

Embodiment 2

[0031] This embodiment provides a drying system for thermoplastic granular materials, including: an accommodation chamber 1 for accommodating materials, the accommodation chamber 1 is arranged in a quadrangular pyramid structure, and an air inlet 2 is arranged outside the accommodation chamber 1, and the air inlet 2 is arranged outside the accommodation chamber 1. The tuyere 2 communicates with the housing chamber 1, the side wall of the air inlet 2 is provided with a heating pipe 21, the side wall of the housing chamber 1 is provided with a number of partition plates 3, and the adjacent partition boards 3 are alternately arranged to form a material supply. The falling moving track, the bottom of the accommodation chamber 1 is provided with a discharge port 4 .

[0032] The above specific improvements are as follows: figure 1 and figure 2 As shown: most of the traditional material holding chambers 1 are circular holding chambers 1, which usually use a screen to separate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com