Refrigerator door transfer device capable of automatically stacking

A transfer device, refrigerator door technology, applied in the direction of unloading device, transportation and packaging, packaging, etc., can solve the problems that the palletizing work cannot be isolated, and the efficiency and convenience of the transfer work cannot be guaranteed, so as to improve the safety of transfer , Transshipment work is convenient and efficient, and the effect of avoiding position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

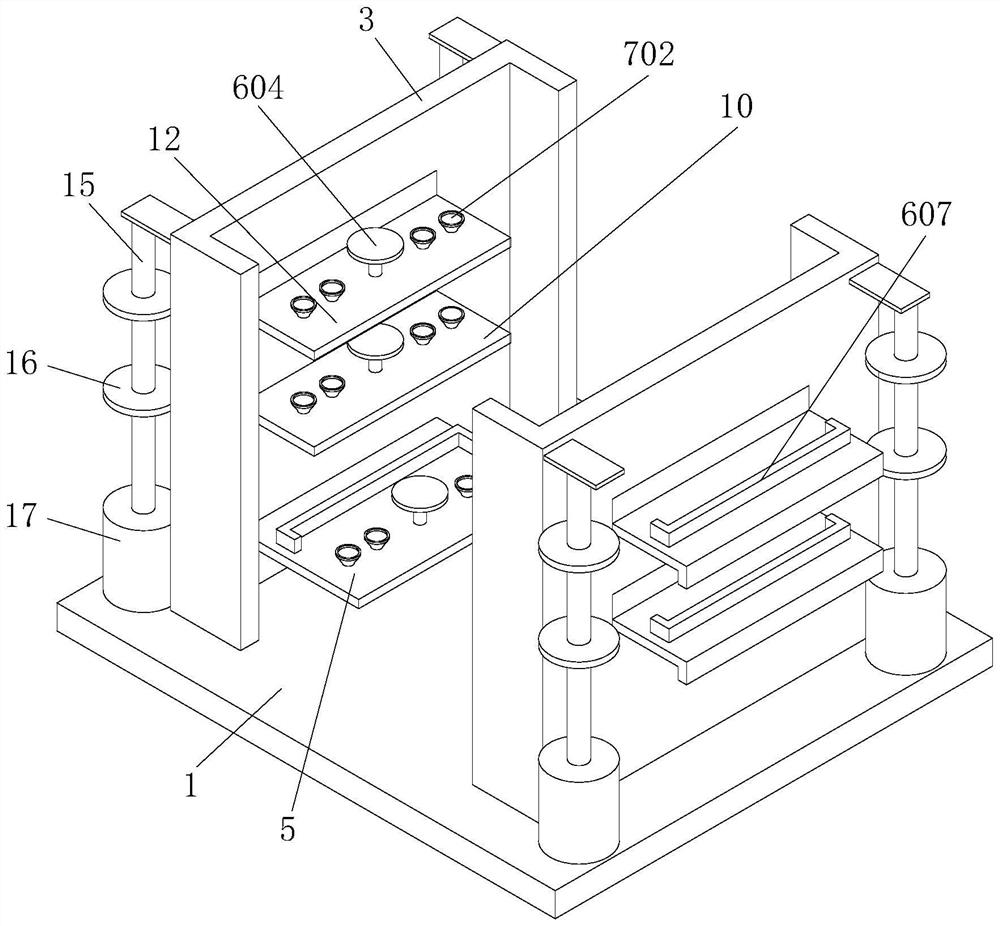

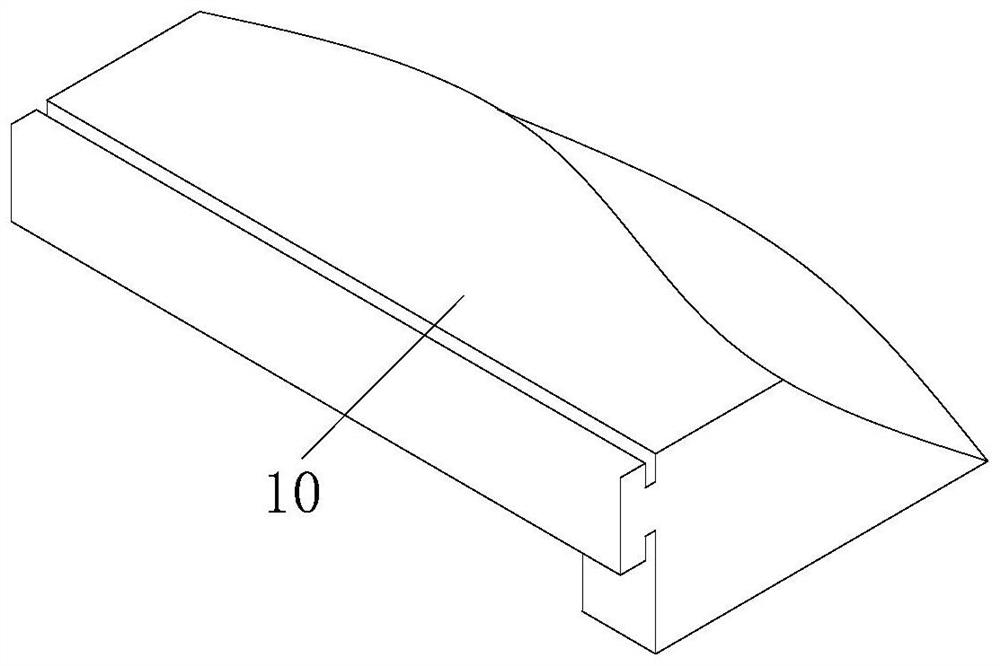

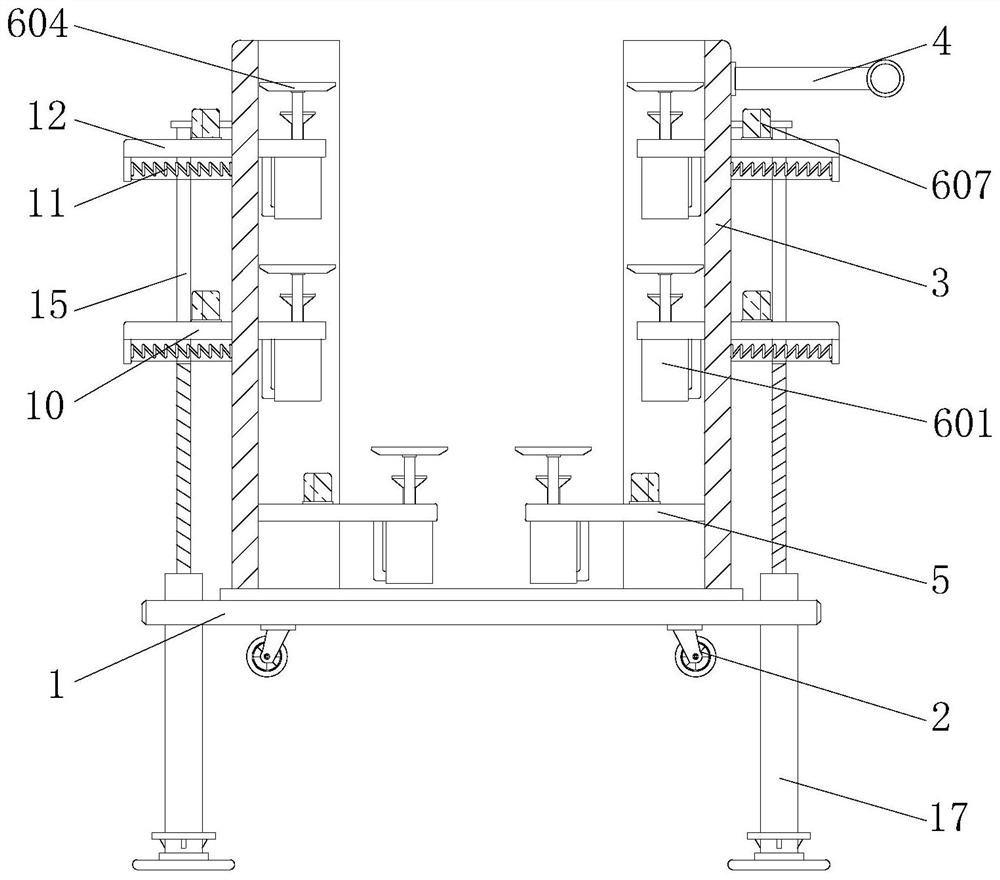

[0036] Such as Figure 1-9 As shown, a refrigerator door transfer device that can be automatically stacked includes a fixed base 1, a universal wheel 2 is installed on the bottom surface of the fixed base 1, and a protective frame 3 is welded and fixed on the top surface of the fixed base 1. The first placement plate 5 is welded and fixed in the frame 3, the second placement plate 10 and the third placement plate 12 are connected with the limit sliding in the protective frame 3, the first placement plate 5, the second placement plate 10 and the third placement plate 12 Clamping and limiting components 6 and adsorption fixing components 7 are installed and fixed on the top, the clamping and limiting components 6 are connected with the ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com