Road surface salt sprinkling and ice melting device

A technology for melting ice and pavement, applied in construction, cleaning methods, etc., can solve the problems of uneven salt spreading and inability to spray salt in a targeted manner, and achieve the effects of avoiding salt agglomeration, increasing the effect, and avoiding local accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

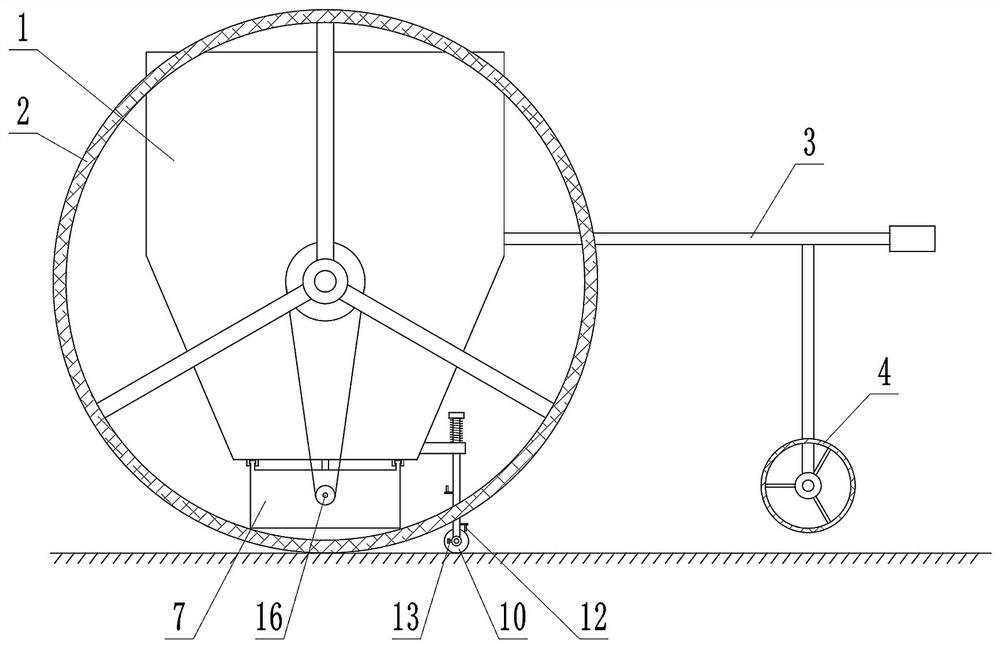

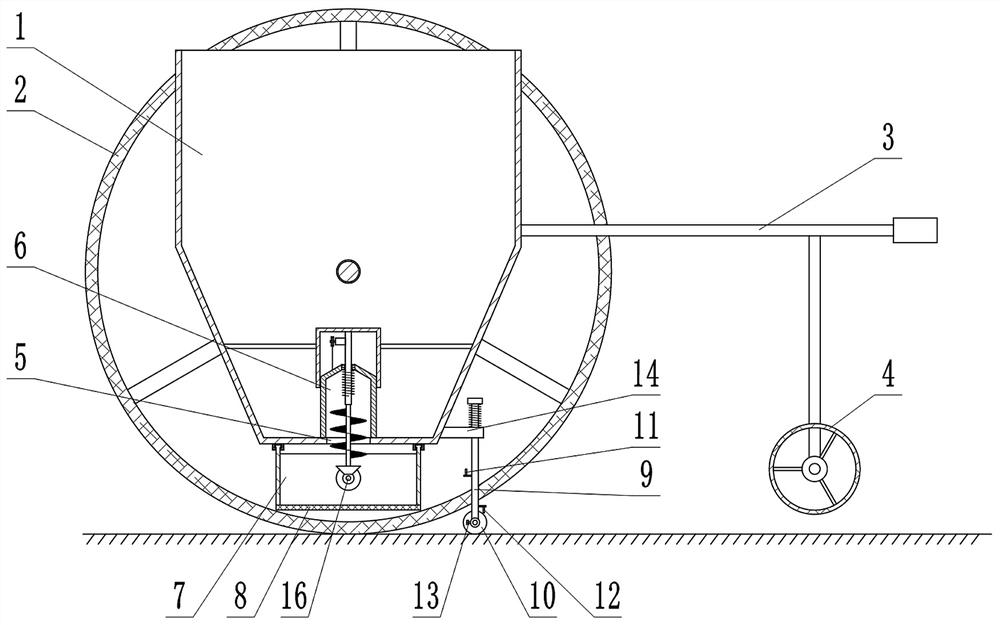

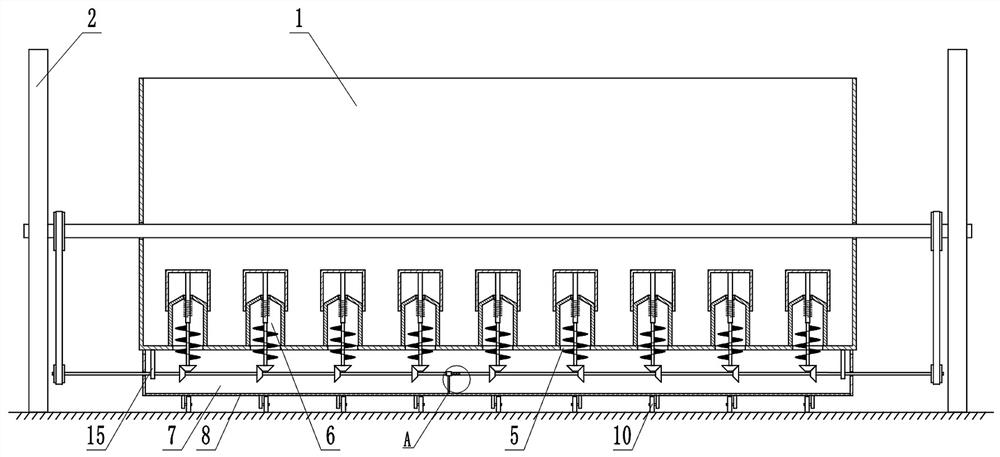

[0028] Depend on Figure 1 to Figure 5 Given, the present invention comprises the silo 1 that is placed in the front and rear directions, and the front and rear sides of the silo 1 are equipped with walking wheels 2; wheel 4;

[0029] The bottom of the silo 1 is provided with a plurality of discharge holes 5, and a distributor 6 is arranged above each discharge hole 5; the distributor 6 can control the discharge speed; the bottom of the silo 1 is equipped with A sieve box 7 capable of reciprocating swing back and forth, the bottom of the sieve box 7 is a screen 8;

[0030] The distributor 6 includes a fixed sleeve 601 placed on the axis of the discharge hole 5, and the upper end of the fixed sleeve 601 is fixed; There is a cover body 604 that can move up and down on the outside, the opening of the cover body 604 is do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com