Simulation turntable for selecting universal wedge-shaped segment splicing point positions

A general-purpose wedge-shaped segment and point position technology, which is applied in shaft equipment, shaft lining, tunnel lining, etc., to achieve the effects of improving construction efficiency, convenient operation, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

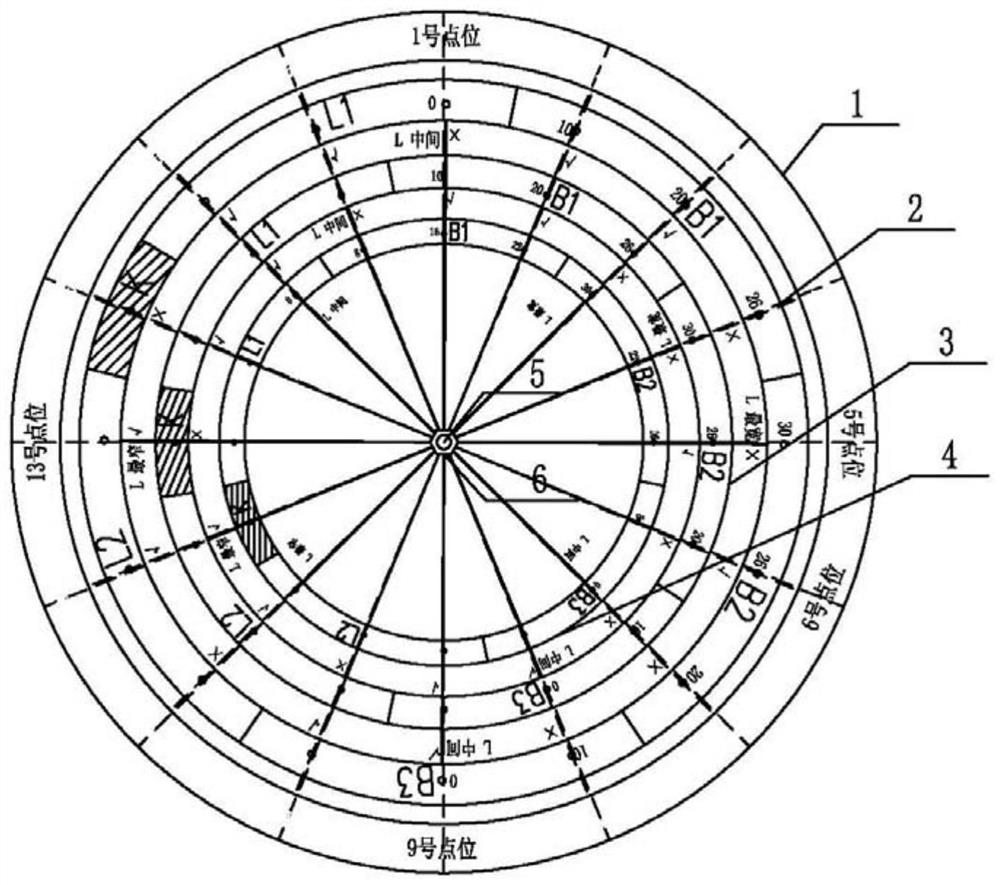

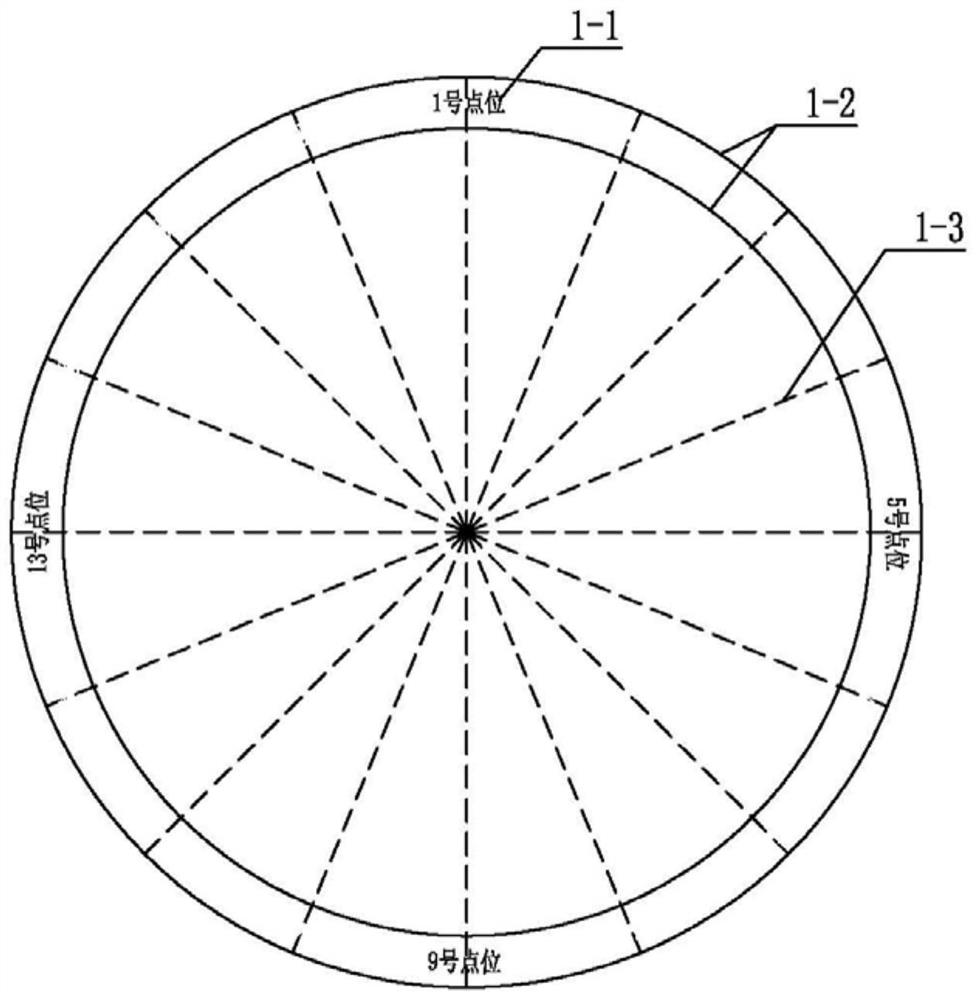

[0022] Such as figure 1 , as shown in 2, the simulated turntable used for general wedge-shaped segment assembly point selection of the present invention includes an assembly point disk 1, an assembly situation disk 2 of the previous ring, an assembly situation disk 3 of the ring to be spliced and a next ring that can be assembled. Assemble the situation plate 4.

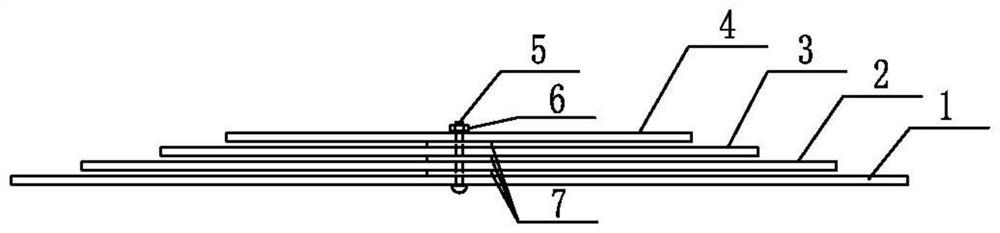

[0023] The assembly point plate 1, the upper ring assembled state plate 2, the to-be-assembled ring assembled state plate 3 and the next ring assembled state plate 4 four discs with different diameters are concentrically layered through the single-head thin bolt 5 Wear them together, put ring gaskets 7 between the discs, and fix the tops of the single-head bolts 5 with nuts 6, thereby making a multi-circle concentric turntable that can rotate at will. Use the assembly point plate 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap