Bolt head protective cap

A head protection and bolt technology, which is used in the field of anti-corrosion of automotive bolts, can solve the problems of weak connection and easy damage to the surface of the bolt head surface anti-corrosion, and achieve the effect of small friction area, reducing corrosion phenomenon and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

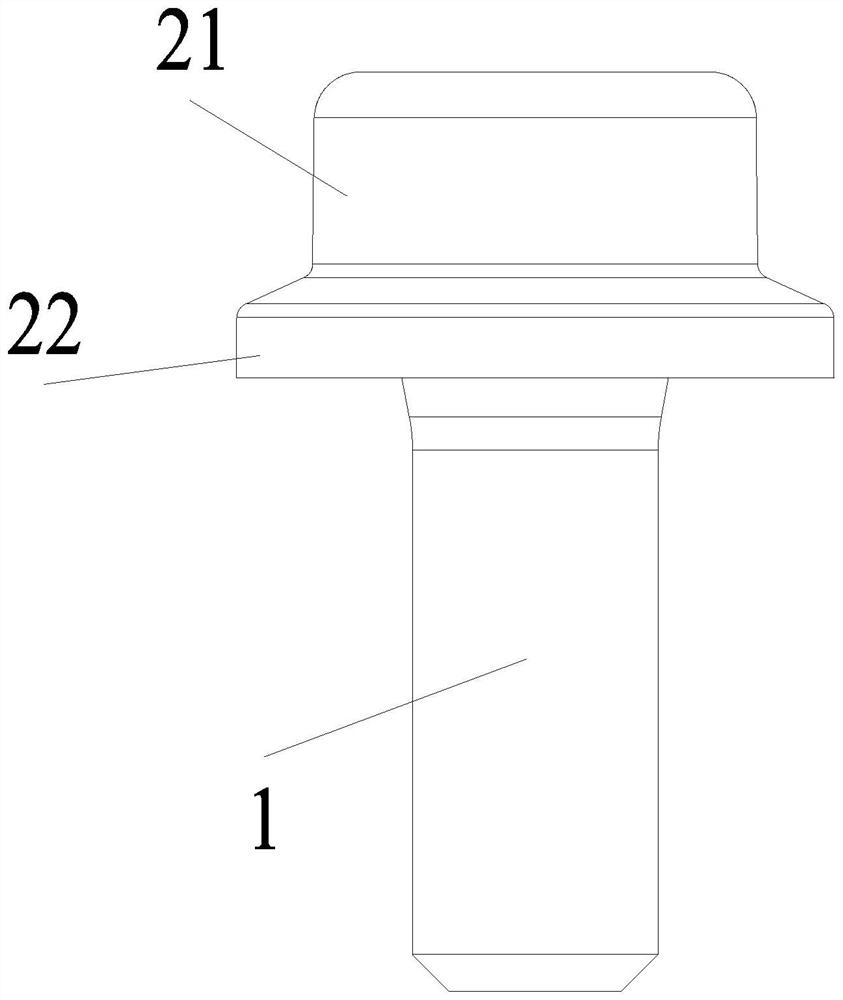

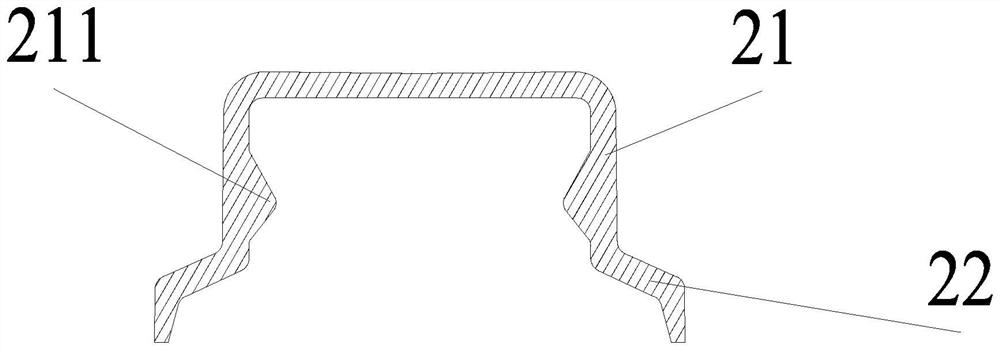

[0023] Such as figure 1 with figure 2 As shown, a bolt head protective cap is used for the protection of hexagonal flange surface bolts 1, and the bolt head protective cap includes a first annular cavity 21 and a second annular cavity 22, and the first annular cavity 21 and the second annular cavity 22 The second annular cavity 22 matches the shape of the bolt, and the middle part of the inner wall of the first annular cavity 21 is provided with an annular protrusion 211 . The first annular cavity 211 cooperates with the head of the bolt, and the second annular cavity 22 cooperates with the flange surface. When the protective cap is installed on the bolt, the annular protrusion 211 interferes with the head of the bolt, thereby achieving The purpose of fixing the protective cap.

[0024] Specifically, the annular protrusion 211 is a structure with a high center and low sides, and the surface area of the annular protrusion 211 away from the inner side wall of the first annu...

Embodiment 2

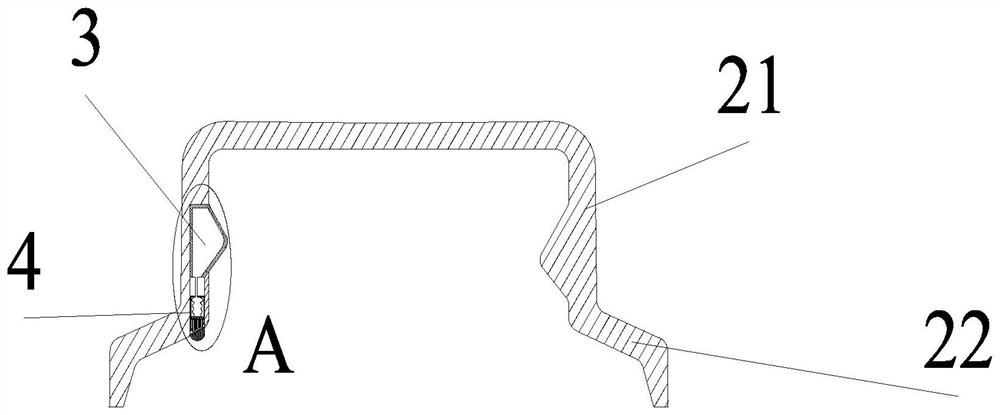

[0027] Such as image 3 with Figure 4 As shown, the annular protrusion 211 is provided with an inflatable cavity 3, and the connection between the first annular cavity 21 and the second annular cavity 22 is provided with an inflatable shell 4, and the inflatable shell 4 is provided with an inflatable device. An air pipe 41 is provided between the inflatable device and the inflatable cavity 3 . During the installation process of the protective cap, the inflator inflates the inflatable chamber 3 in the inflatable shell 4 through the air pipe 41, so that the annular protrusion 211 is higher than the inner wall surface of the first annular chamber 21, and interferes with the bolt 1, so as to achieve the bolt The purpose of fixing the head protection cap on the bolt 1; in addition, the gas is compressible and more flexible than ordinary flexible materials, which is more conducive to reducing the damage of the bolt head protection cap to the anti-corrosion agent on the bolt surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com