Clamping seat profile for improving tuyere mounting efficiency

A technology of installation efficiency and card seat, applied in the direction of pipeline layout, etc., can solve problems such as damage, inability to protect the tuyere, short service life, etc., and achieve the effects of improved positioning, convenient installation, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

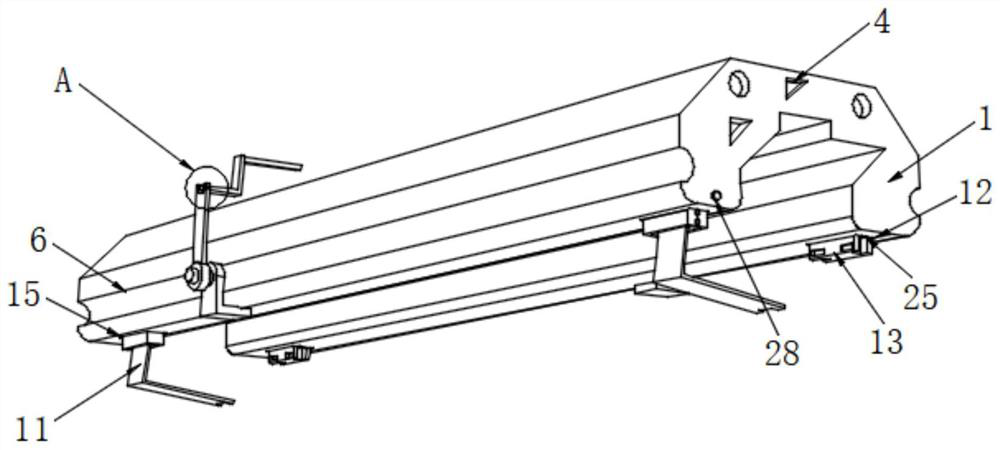

[0032] Such as figure 1 , figure 2 , Figure 6 and Figure 7 As shown, a card holder profile that improves the installation efficiency of the tuyere, including a card holder body 1, two positioning grooves 2, four card holder screw holes 3, two support frame screw holes 4, injection molded holder grooves 5, two Accessory slots 6, two auxiliary plates 7, multiple first card slots 8, two rollers 9, two drums 10, two straps 11, two auxiliary slots 12, two mounting blocks 13, four Second card slot 14, two grooves 15, two clamping blocks 16, two connecting shafts 17, two installation sleeves 18, two movable rods 19, two installation shafts 20, two first protective plates 21. Two second protective plates 22, two clamping plates 23, four blocks 24, four sliders 25, four chute 26, two springs 27 and two limit posts 28, the card seat body 1. There are positioning grooves 2 on both sides of the top. Two card screw holes 3 are opened on the front and back of the card holder body 1. ...

Embodiment 2

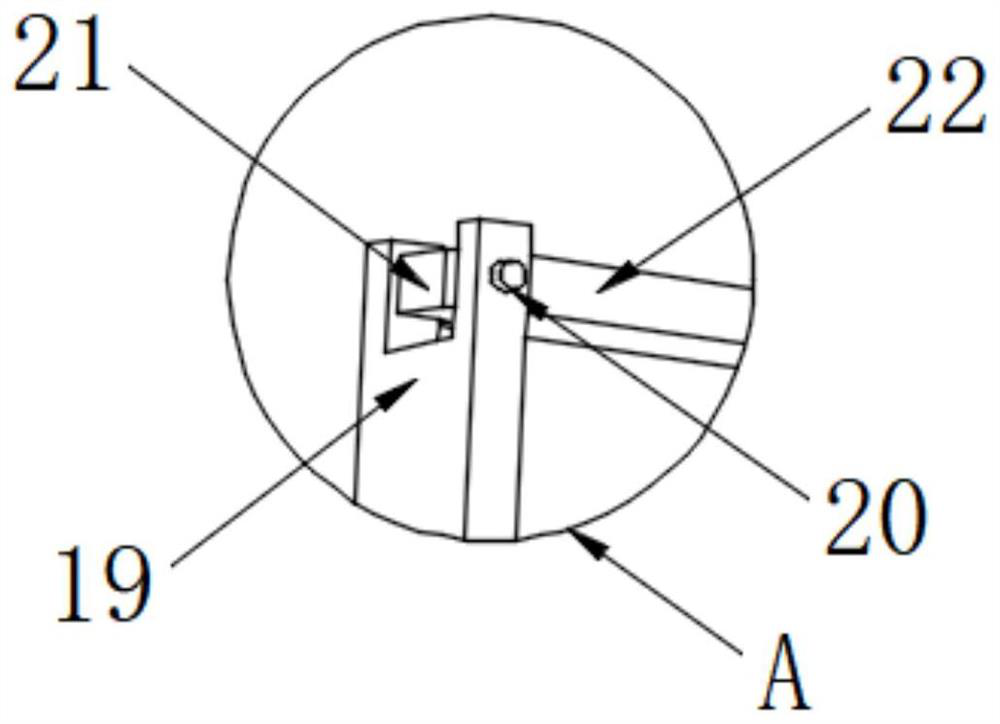

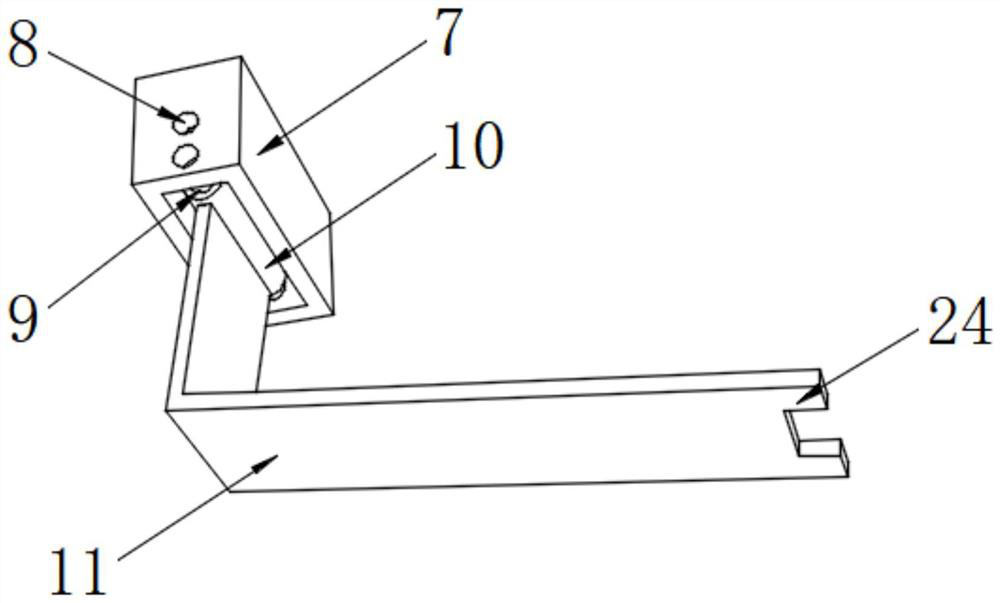

[0034] On the basis of Example 1, as image 3 , Figure 4 and Figure 5 As shown, one end of the two rotating rollers 9 is movably sleeved with the two rotating cylinders 10 respectively, and the outside of the two rotating cylinders 10 is wound with a binding belt 11, and one side of the two binding belts 11 is fixedly installed with two Block 24, two auxiliary grooves 12 are provided at the bottom of the card holder body 1, and one side of the two movable rods 19 is connected with an installation shaft 20, and one end of the two installation shafts 20 is movably sleeved with a first Protective plate 21, one side of two first protective plates 21 is hinged with second protective plate 22, one side of two second protective plates 22 is all hinged with clamping plate 23, two clamping plates 23 The length is greater than the length of the two second protective plates 22, and the positions of the two second protective plates 22 are corresponding. , the clamping block 16 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com