Cooling triangular unit provided with flow equalizing device with middle jet flow gap

A cooling triangle and gap technology, which is applied in the direction of indirect heat exchangers, fixed conduit components, lighting and heating equipment, etc., can solve the problems of cooling column cooling capacity drop, eddy current formation, etc., to achieve the effect of eliminating eddy current and improving the overall cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

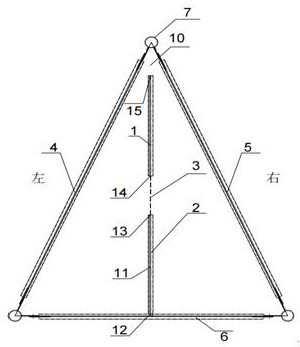

[0023] Example 1 is a cooling triangulation unit of a current flow apparatus mounted with a medium jet gap in a porosity of 0.

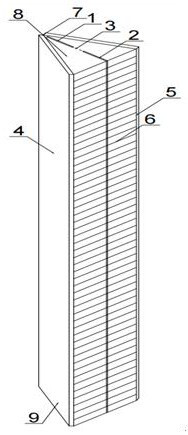

[0024] Such as Figure 4 As shown, the present invention is provided with a cooling triangulation unit of a current flow device having a central portion jet gap comprising a cooled triangulation unit and a medium-end device with a central jet gap; the vertical height of the cooling triangulation unit is 30m, cooling triangular unit The vertical distance of the angle bracket 7 to the in-air shutters 6 is 2.5m, and the length of the flow of the medium jet gap is 1.5m from the cooled triangular unit top surface 8, and the cooled triangle is cooled from the medium-to-circular jet gap. The spacing Hc of the unit bottom surface 9 is 2.5m; the current flow device of the inner jet gap includes an outer homogeneous plate 2, an inner homogenizing plate 1, and a medium jet gap 3, and the outer cube plate 2 along the cooling triangulation unit vertical center symmetr...

Embodiment 2

[0028] Example 2 is a cooling triangulation unit having a porosity greater than 0 is attached to a cosmetic device with a medium jet gap.

[0029] Such as Figure 5 As shown, the present invention is provided with a cooling triangulation unit of a current flow device having a central portion jet gap comprising a cooled triangulation unit and a medium-end device with a central jet gap; the vertical height of the cooling triangulation unit is 30m, cooling triangular unit The vertical distance of the angle bracket 7 to the air shutters 6 is 2.5m, the web of the medium jet gap is 1m from the cooled triangular unit top surface 8, and the spacing Hc of the bottom surface 9 of the cooling triangulation unit 9 is 2m; outer side Substream 2 along the cooling triangular unit vertical center symmetry surface 11 self-inverted shutters 6 inwardly extending the distance LW is 0.5m; the inner homogeneous cube plate 1 along the cooling triangulation unit vertical center symmetry surface 11 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com