Automatic filling skin production line for combined fireworks

A technology for automatic loading and assembling fireworks, which is applied in pyrotechnics, offensive equipment, weapon types, etc. It can solve the problems of unguaranteed yield rate, poor product consistency, and low work efficiency, and achieve simple and reliable structure, simple structure, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

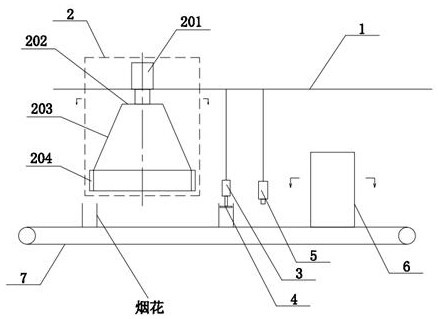

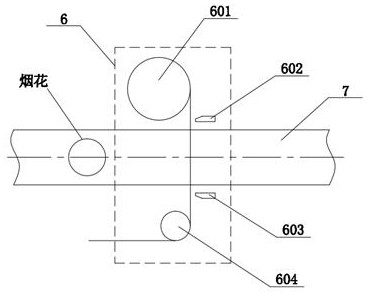

[0020] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it comprises a hanger 1 and a conveyor belt 7, the hanger 1 is an I-beam, and a material distribution device 2 is provided between the hanger 1 and the conveyor belt 7, and the material distribution device The rear end of 2 is provided with a cylinder 3, the push rod end of the cylinder 3 is provided with a pressure plate 4, the rear end of the cylinder 3 is provided with a detection device 5, and the rear end of the detection device 5 is provided with a skinning device 6;

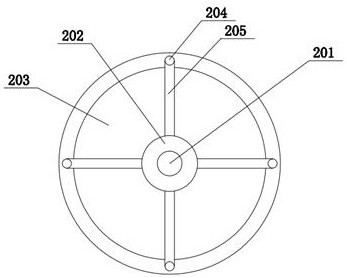

[0021] Described distributing device 2 comprises motor 201, and motor 201 is geared motor, and the below of motor 201 is provided with distributing tray 202, and the below of distributing tray 202 is provided with distributing slide plate 203, and the bottom edge of distributing slide plate 203 is provided with Material distribution port 204, the diameter of material distribution port 204 is smaller than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com