Data model of resource environment load in casting process

A technology of environmental load and casting process, which is applied in the field of data model of resource and environmental load of casting process to achieve the effect of solving organizational and management problems and maintaining data integrity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

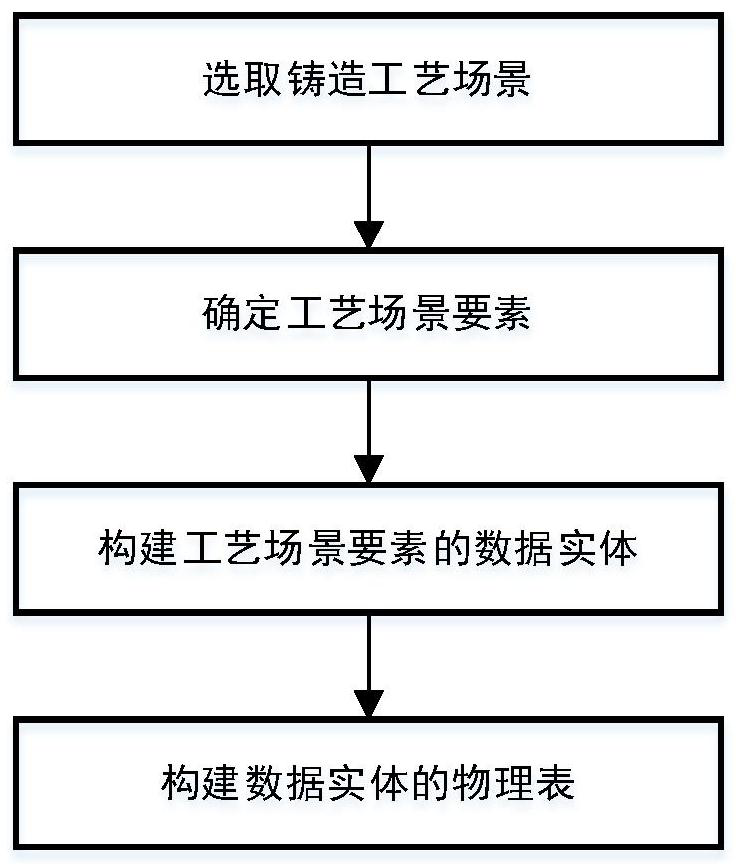

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with the accompanying drawings, the preferred embodiments of the present invention are described in detail:

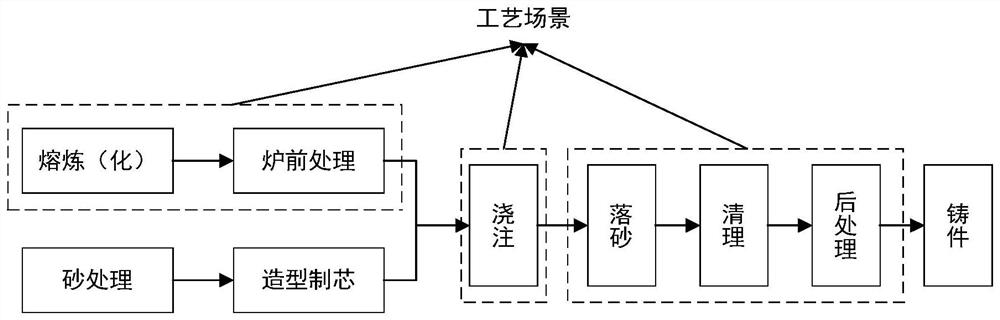

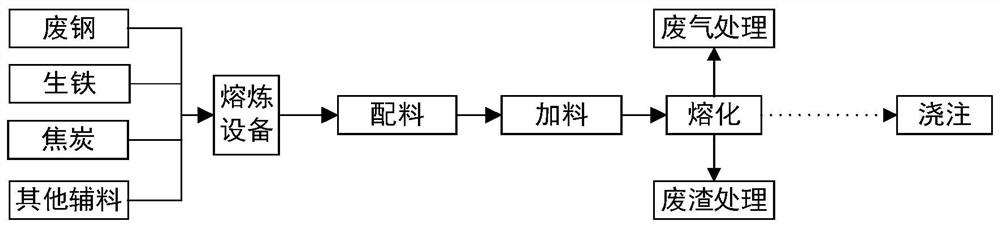

[0054] The main part of a typical sand casting process is as follows: figure 2 As shown, one or more processes in the process can be selected and named as a process scene. In this embodiment, the smelting process of the casting process is selected as the smelting process scene. The components of the smelting process scene are shown as follows image 3 , which includes the main links of batching, feeding, melting, and pouring.

[0055] Define the constituent elements of the smelting process scene, which are the basic description of the process scene, process objects, equipment, energy, key process parameters, auxiliary materials, environmental loads, and output components. According to the elements contained in the smelting process scene, the data of the elements of the smelting process scene are constructed respectively. Entity, the basic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com