Dry-type box capacitor potting process

A technology for capacitors and boxes, which is applied in the field of potting technology for dry-type box capacitors, can solve the problems that the potting process cannot meet the requirements, and achieve the effects of ensuring partial discharge performance, improving reliability and service life, and ensuring insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

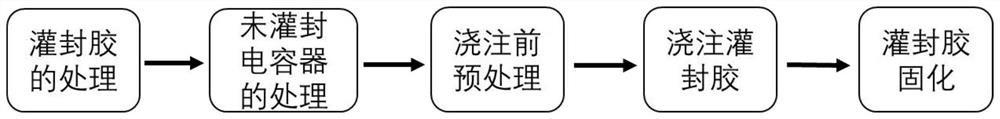

[0024] Dry box capacitor potting process of the present invention, such as figure 1 As shown, the following steps are included: treatment of the potting compound, treatment of the unpotted capacitor, pretreatment before pouring, pouring of the potting compound, and curing of the potting compound.

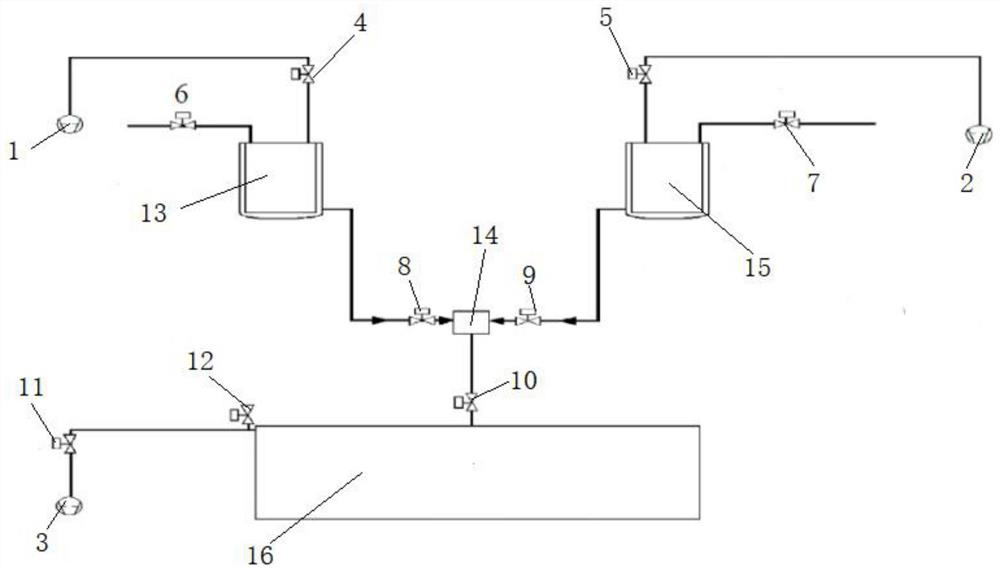

[0025] Such as figure 2 As shown, turn on the vacuum pump A1 and vacuum pump B2, the evacuation valve A4 and the evacuation valve B5, and when the air pressure in the vacuum tank A13 and the vacuum tank 15 is 80-150Pa, open the feed valve A6 and the feed valve B7, respectively pour the potting glue The A and B components of the potting glue are pumped into the vacuum tank A13 and the vacuum tank B15 for stirring, and the A and B components of the potting glue are all pumped into the vacuum tank A13 and the vacuum tank B15, and then the feed valve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap