Intelligent disassembling method and device for waste high-value circuit board chip

A circuit board, high-value technology, applied in the field of resources and environment, can solve the problems of few recycling chains, narrow selection of dismantling chips, slow chip disassembly, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

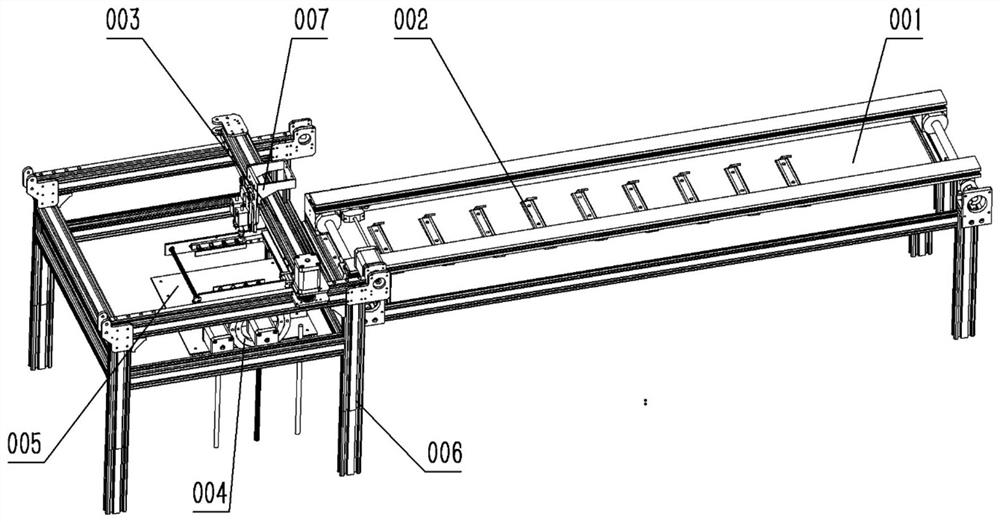

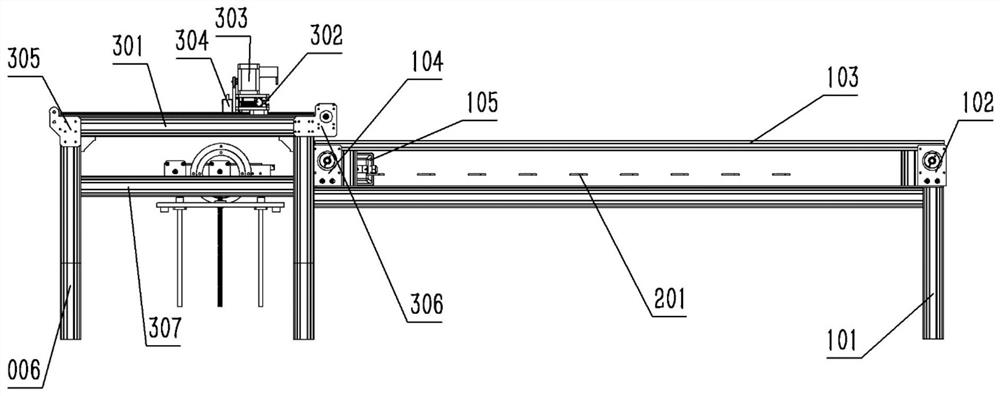

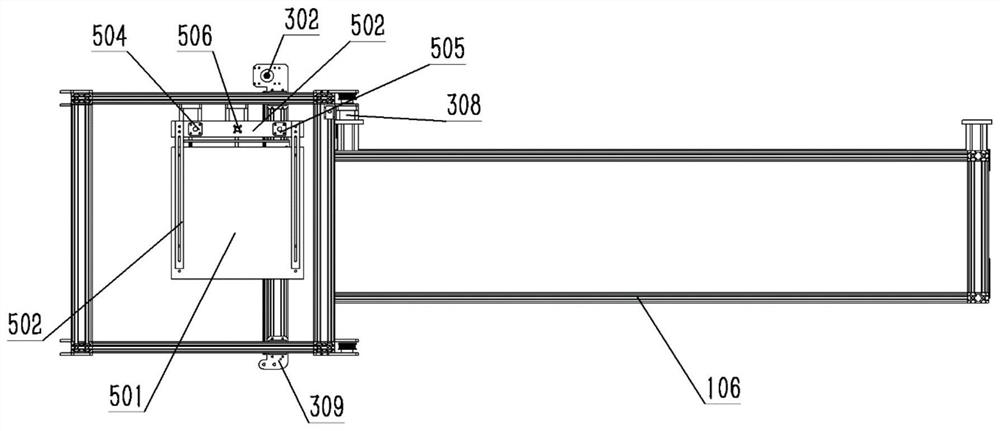

Embodiment 1

[0049] Taking the Huawei P9 mainboard chip as the dismantling target, after adjusting the width of the feeding movable guide rail 106 to 66mm, guide the three positioning points on the mainboard surface into the upper computer of the back-end chip dismantling and sorting unit 003, and at the same time place the upper part of the mainboard CPU chip The metal shield, the location marks of the CPU and memory chips. Firstly, the temperature of the temperature sensor 105 at the outlet of the heat treatment unit 001 is set to 230°C, and the temperature of the heating bottom plate 501 of the heat preservation heating platform 005 is set to 235°C. Put the main board of the mobile phone into the fixed guide rail 103 in sequence, and turn it on to prepare for heating operation. After the temperature of the heating end reaches the standard and the indicator light turns on, start the conveyor belt to start feeding. The circuit board enters the back-end heat preservation and heating platf...

Embodiment 2

[0051] Taking the Huawei P9 mainboard chip as the dismantling target, after adjusting the width of the feeding movable guide rail 106 to 66mm, guide the three positioning points on the mainboard surface into the upper computer of the back-end chip dismantling and sorting unit 003, and at the same time place the upper part of the mainboard CPU chip The metal shield, the location marks of the CPU and memory chips. Firstly, the temperature 105 at the outlet of the heat treatment unit 001 is set to 240°C, and the temperature of the heating bottom plate 501 of the heat preservation and heating platform 005 is set to 245°C. Put the main board of the mobile phone into the fixed guide rail 103 in sequence, and turn it on to prepare for heating operation. After the temperature of the heating end reaches the standard and the indicator light turns on, start the conveyor belt to start feeding. The circuit board enters the back-end heat preservation and heating platform 005 in turn, the r...

Embodiment 3

[0053]Taking the Huawei P9 mainboard chip as the dismantling target, after adjusting the width of the feeding movable guide rail 106 to 66mm, guide the three positioning points on the mainboard surface into the upper computer of the back-end chip dismantling and sorting unit 003, and at the same time place the upper part of the mainboard CPU chip The metal shield, the location marks of the CPU and memory chips. First, set the temperature of the temperature sensor 105 at the outlet of the heat treatment unit 001 to 250°C, and set the temperature of the heating base plate 501 of the heat preservation heating platform 005 to 255°C. Put the main board of the mobile phone into the fixed guide rail 103 in sequence, and turn it on to prepare for heating operation. After the temperature of the heating end reaches the standard and the indicator light turns on, start the conveyor belt to start feeding. The circuit board enters the back-end heat preservation and heating platform 005 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com