Method for adjusting backlash between pinion and rack in rack-pinion drive

A driving device, pinion technology, applied in the direction of transmission, friction transmission, transmission parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

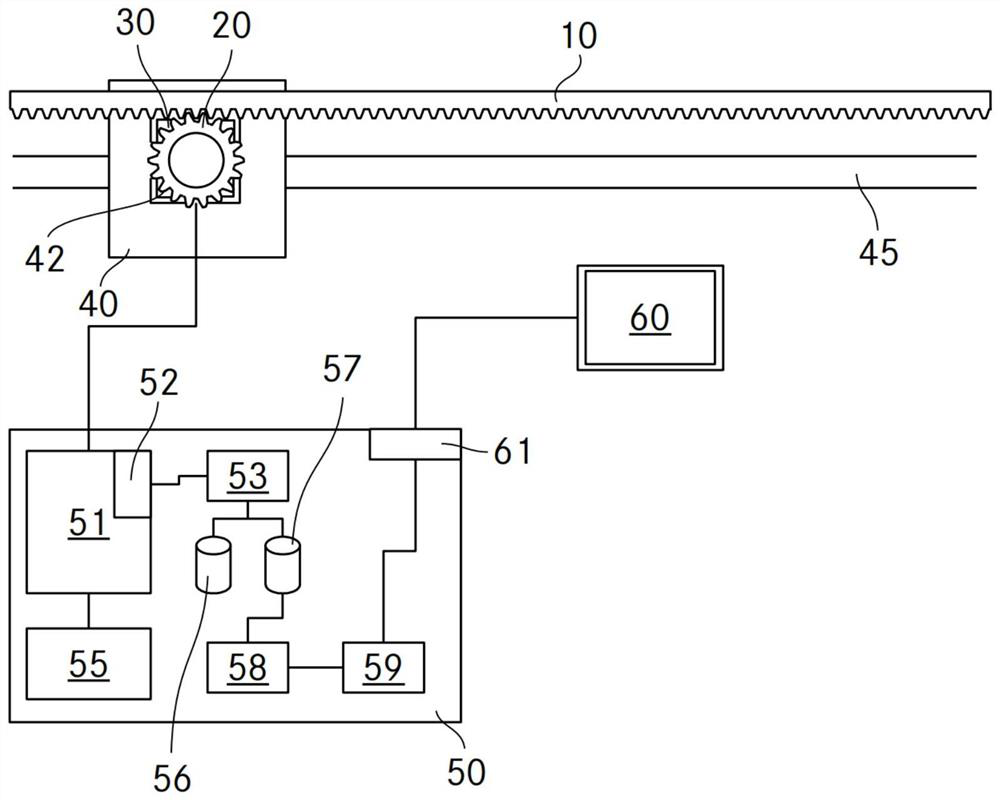

[0078] figure 1 is a schematic diagram of a rack-pinion drive according to the present invention. The rack-pinion drive comprises a rack 10 meshing with a pinion 20 . Pinion 20 is driven by a motor-gearbox assembly 30 comprising an electric drive motor and a planetary gearbox. In such a known manner, the motor-gearbox assembly 30 is mounted on a carriage 40 (as a carrier for the motor-gearbox assembly), movable linearly on linear guides 45 along the toothed rack 10 . The motor-gearbox assembly 30 is mounted to the bracket through a positioning mechanism 42 , which can precisely position the assembly in a radial position relative to the rack 10 . A suitable positioning mechanism 42 includes an eccentric support for the motor-gearbox assembly 30, wherein the motor-gearbox assembly 30 is rotated at an angle corresponding to the radial adjustment distance to achieve precise radial adjustment. As mentioned above, such mechanisms are disclosed in WO2017 / 216306A1 (Güdel Group). I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com