V2500 engine sliding door tip repair hyperboloid appearance recovery method

A recovery method and technology of sliding doors, which are applied in the field of aircraft maintenance, can solve problems such as not meeting the safety technical requirements of reverse thrust, difficult quantitative recovery of hyperbolic shape, and affecting the control of reverse thrust, so as to achieve low production cost, reliable performance, and low cost. The effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

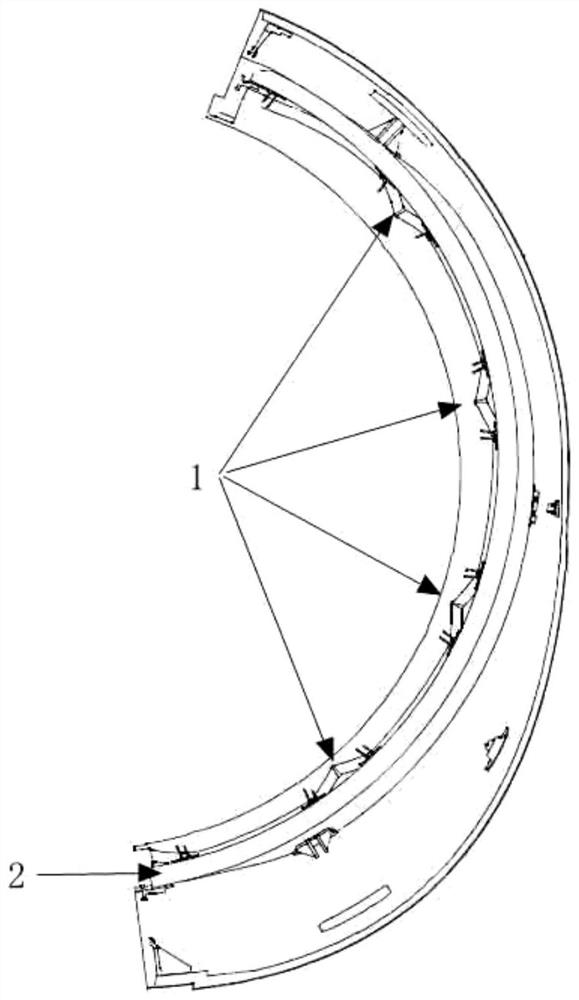

[0036] Such as figure 1 As shown, the V2500 engine translation door tip repair hyperboloid shape recovery method provided in this embodiment includes the following steps:

[0037] (1) Select the protruding metal ring 2 on the lower side of the tip 1 of the V2500 engine translation door as the reference plane, measure the distance between the tip and the selected reference plane, take the average value of 39mm from the three measurements as the value for measuring the tilt height of the tip;

[0038] A qualified scale is used here. It is known that the tip of the V2500 engine translation door is a hyperboloid shape. The transverse curved surface can be restored according to the original skin, and the longitudinal curved surface needs to be restored according to the height of the tip tilt. Therefore, the tip tilt height in the whole method The measurement and acquisition of numerical values is the most important basis for the recovery of hyperboloid shape.

[0039] (2) Since ...

Embodiment 2

[0046] Such as figure 1 As shown, the V2500 engine translation door tip repair hyperboloid shape recovery method provided in this embodiment includes the following steps:

[0047] (1) Select the protruding metal ring 2 on the lower side of the V2500 engine translation door tip 1 as the reference plane, measure the distance between the tip and the selected reference plane, and take the average value of 40mm from the three measurements as the value for measuring the tilt height of the tip;

[0048] A qualified scale is used here. It is known that the tip of the V2500 engine translation door is a hyperboloid shape. The transverse curved surface can be restored according to the original skin, and the longitudinal curved surface needs to be restored according to the height of the tip tilt. Therefore, the tip tilt height in the whole method The measurement and acquisition of numerical values is the most important basis for the recovery of hyperboloid shape.

[0049] (2) Since the...

Embodiment 3

[0056] Such as figure 1 As shown, the V2500 engine translation door tip repair hyperboloid shape recovery method provided in this embodiment includes the following steps:

[0057] (1) Select the protruding metal ring 2 on the lower side of the V2500 engine translation door tip 1 as the reference plane, measure the distance between the tip and the selected reference plane, and take the average value of 41mm from the three measurements as the value for measuring the tilt height of the tip;

[0058] A qualified scale is used here. It is known that the tip of the V2500 engine translation door is a hyperboloid shape. The transverse curved surface can be restored according to the original skin, and the longitudinal curved surface needs to be restored according to the height of the tip tilt. Therefore, the tip tilt height in the whole method The measurement and acquisition of numerical values is the most important basis for the recovery of hyperboloid shape.

[0059] (2) Since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com