Novel process for integrally prefabricating and hoisting herringbone frame of deepwater jacket

A technology of overall prefabrication and overall hoisting, applied in the field of offshore oil engineering, can solve the problems of difficult hoisting, easy shaking in hoisting, and difficult construction, and achieve the effect of reducing the number of high-altitude hoisting, solving the difficulty of construction and improving market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the invention.

[0030] Such as Figure 1-4 Shown, the present invention adopts following steps:

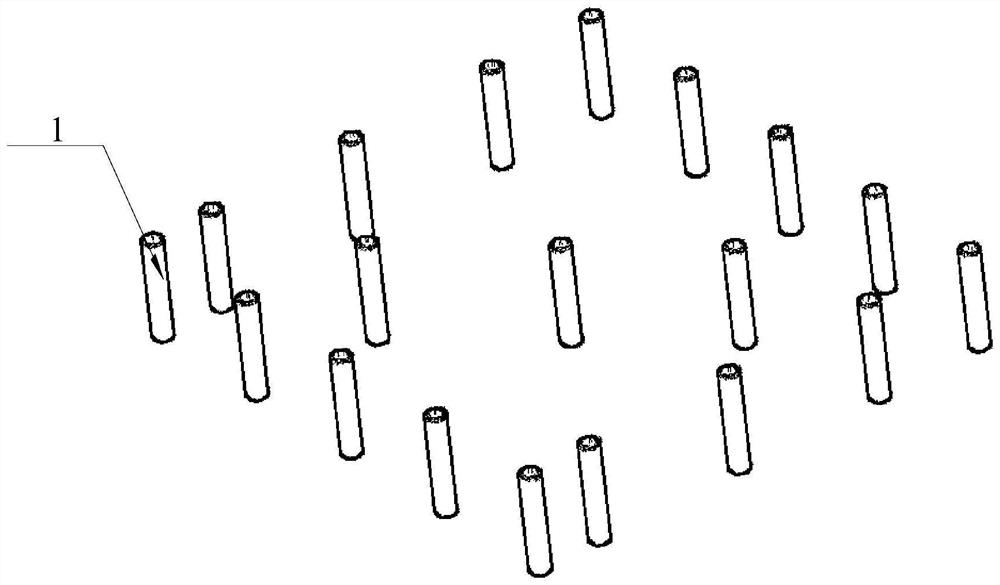

[0031] first step, such as figure 1 As shown, on a flat prefabricated site, place the pier 1 required for the prefabrication of the bottom horizontal sheet 2 according to the prefabrication scheme, and perform measurement and leveling.

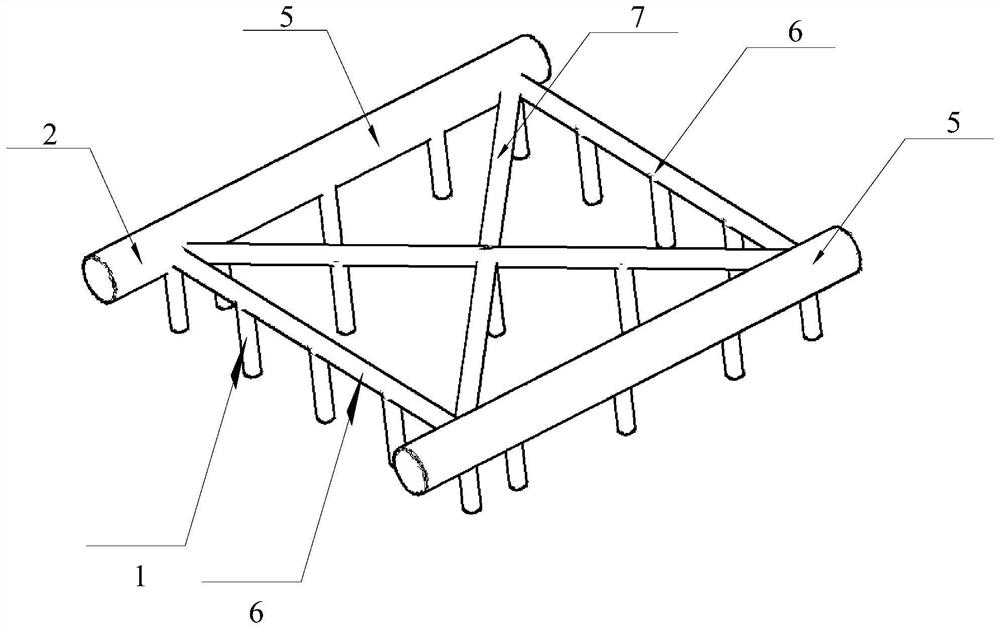

[0032] The second step, such as figure 2 As shown, on the designated pier 1, the bottom horizontal sheet 2 is prefabricated, and the measurement, adjustment and positioning are carried out. After the appearance inspection is passed, all welding is completed according to the welder's process specification, and the inspection after welding is passed.

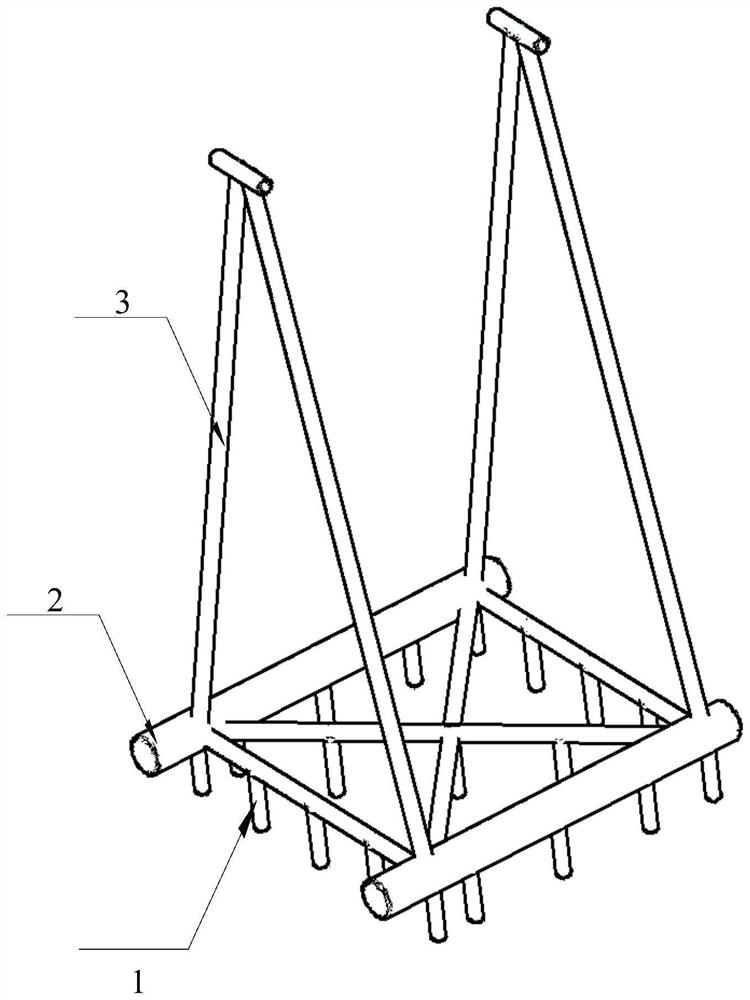

[0033] The third ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com