A nuclear power station annular double-layer steel plate wall structure whole-circle hoisting tool and method

A hoisting method and technology of nuclear power plants, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of frequent use of cranes, high-altitude operations, high hoisting safety risks, and high installation accuracy requirements of SC structural modules, to ensure that The effect of construction quality and safe construction, reducing the amount of high-altitude operations on site, and reducing the number of high-altitude hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples.

[0036] A ring-shaped double-layer steel plate wall structure hoisting tool and method for the entire circle of a nuclear power plant comprises the following steps:

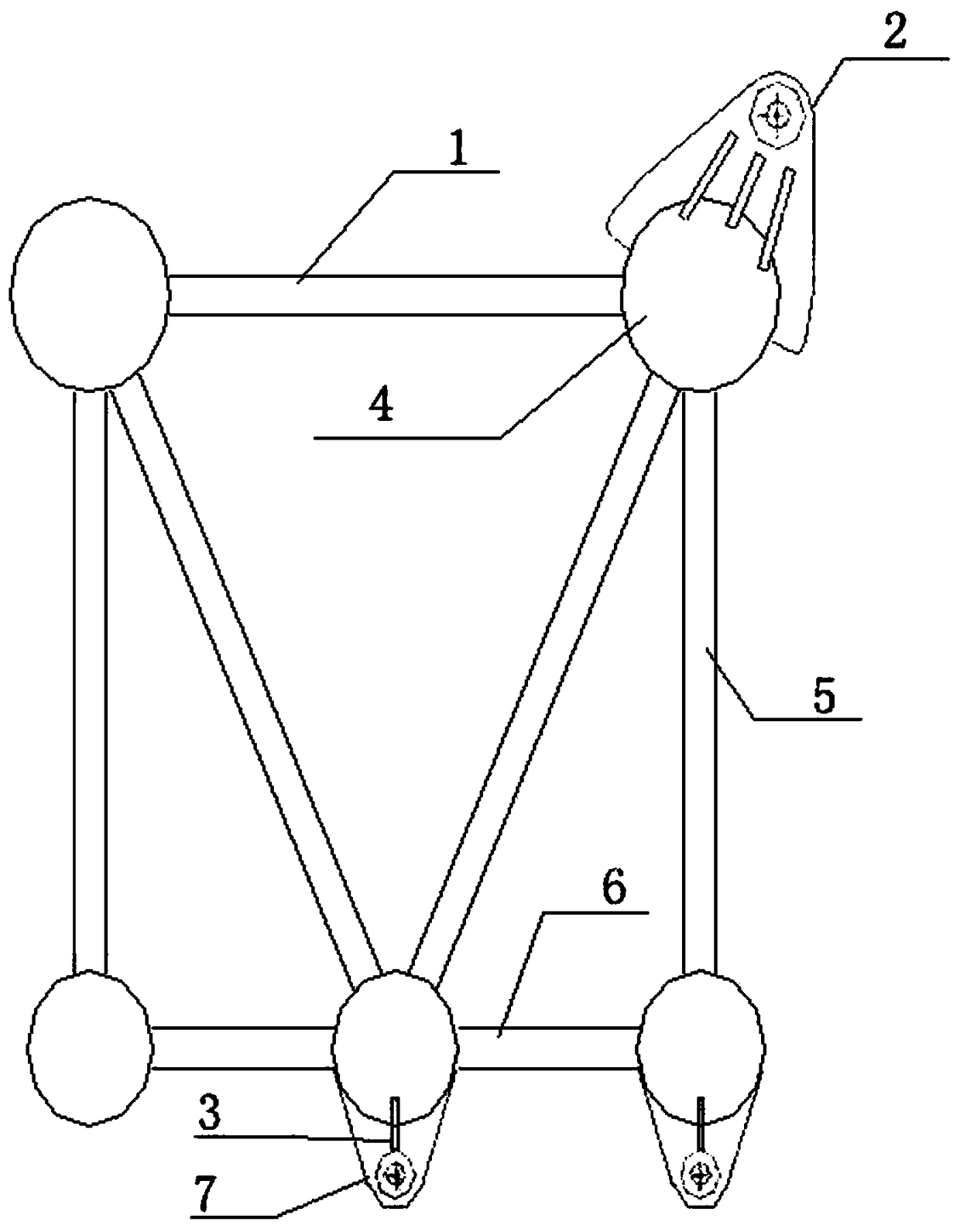

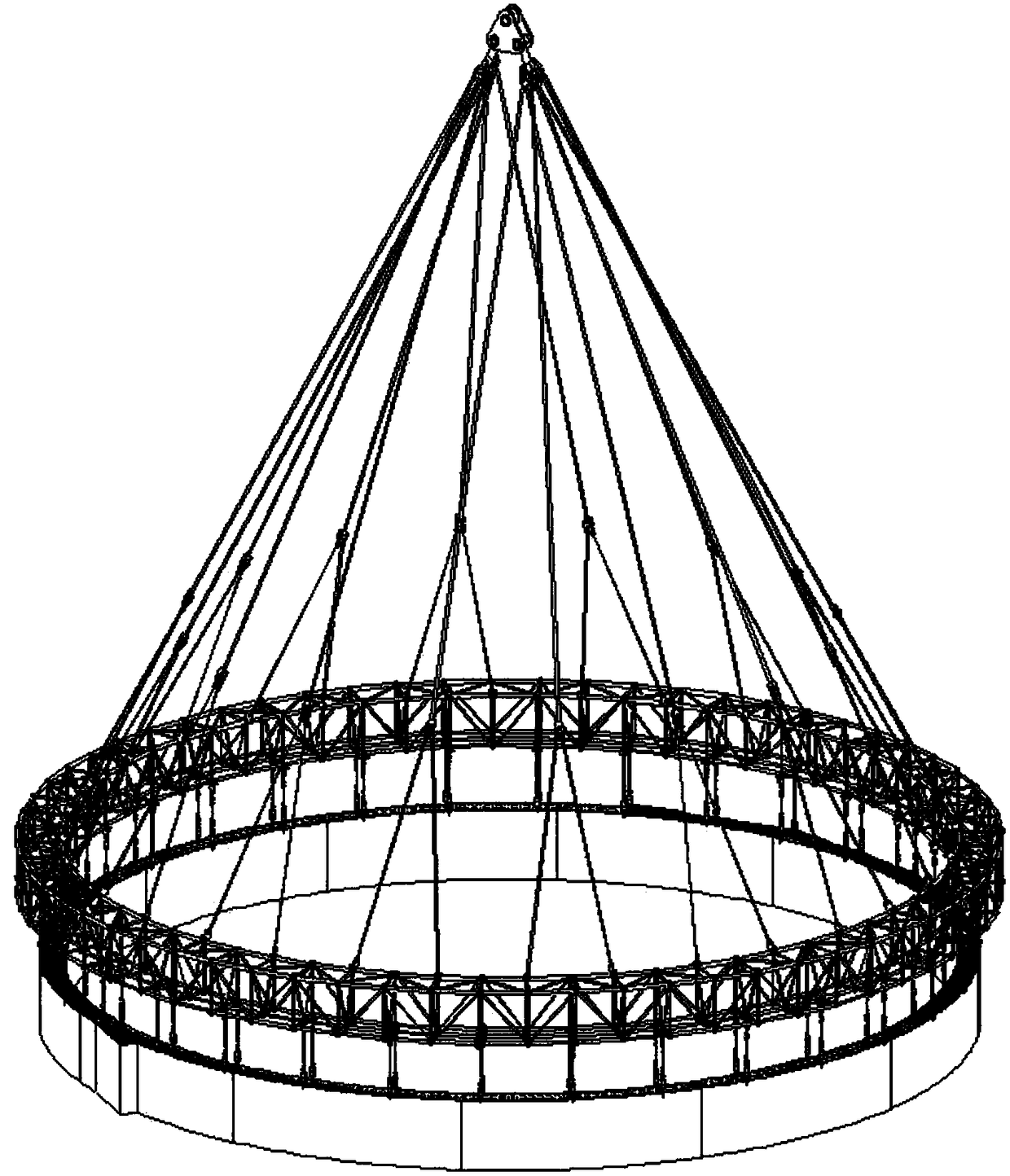

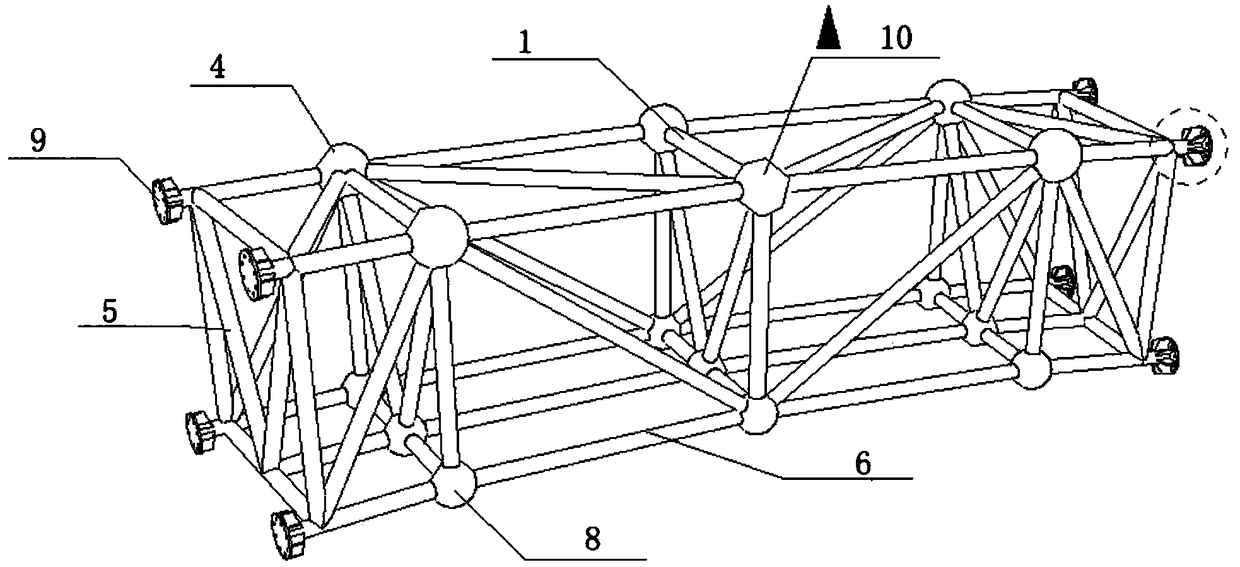

[0037] 1. Determine the number and weight of lifting points according to the weight of the lifting module:

[0038] For the hoisting of the SC module, the hoisting weight at the upper and lower hoisting points is determined according to the hoisting weight. In order to distribute the load evenly, the hoisting load of the whole circle is evenly distributed on the lower nodes of the inner and outer rings and should be vertically downward. The node load and the number of lifting points should be appropriate and meet the requirements of structural strength, stability and manufacturing economy. The number of hoisting points should be determined according to the conditions of the slings on site. Generally, the force of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com