Temperature type transmitter convenient for heat dissipation

A technology of transmitter and heat dissipation box, which is applied to thermometers, thermometers, and thermometer components that are directly sensitive to heat, can solve the problems of dust accumulation in heat dissipation windows, decreased heat dissipation effect, and single structure. , to facilitate cleaning and replacement, facilitate heat dissipation, and ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

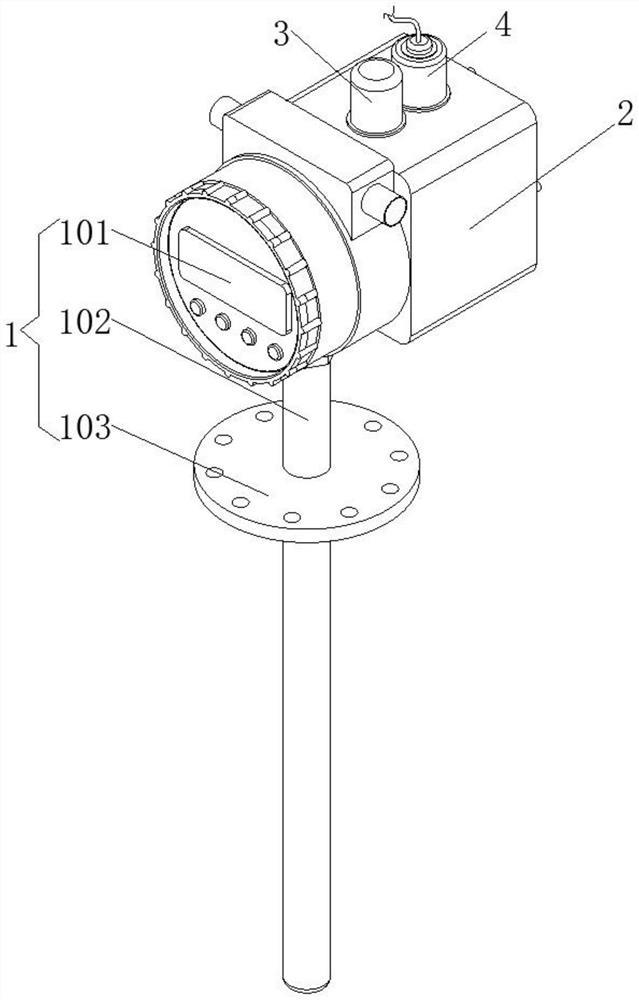

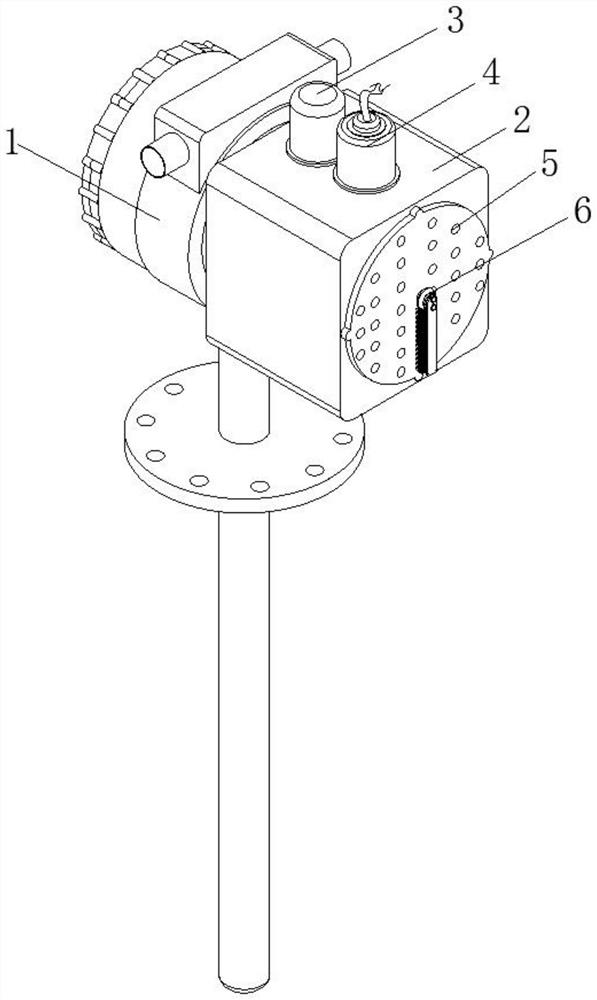

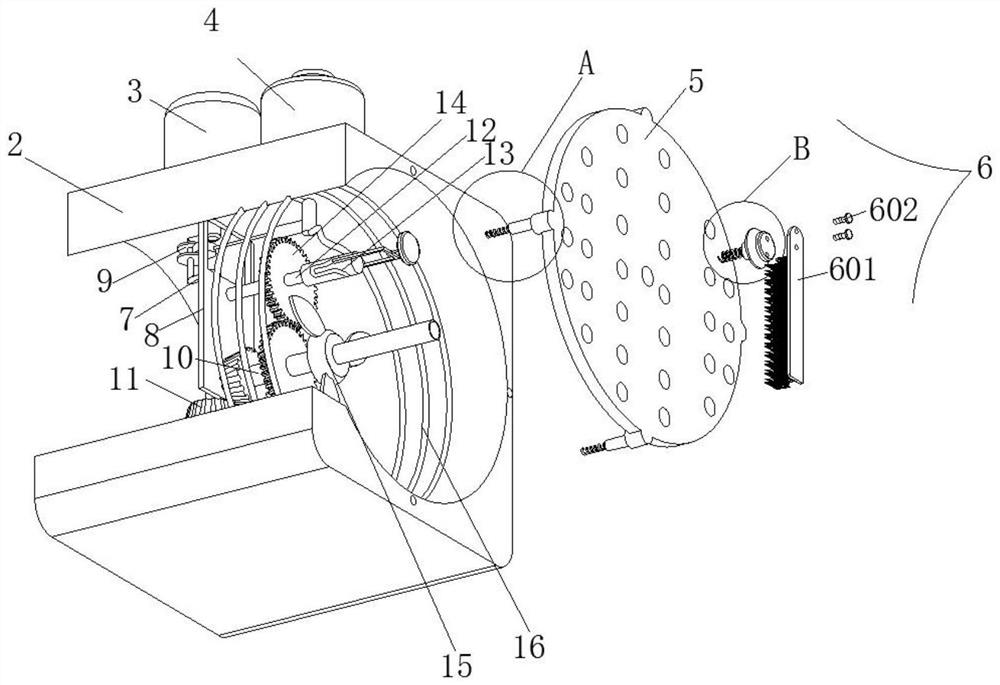

[0035] like Figure 1-7 As shown, the present invention provides a technical solution: a temperature-type transmitter that is convenient for heat dissipation, including an instrument assembly 1 and a circular hollow cooling box 2 fixed on the back of the instrument assembly 1 without a front panel. The instrument assembly 1 Including a transmitter body 101, the bottom of the transmitter body 101 is provided with a probe rod 102 for temperature measurement processing, and a flange 103 is provided on the rod body of the probe rod 102 for fixed installation, and the back of the transmitter body 101 is set There is a heat conduction plate within the range of the heat dissipation box 2, which guides the heat dissipated in the transmitter body 101 to the heat conduction plate, and a small servo motor 3 is fixed on the top of the heat dissipation box 2, and on the back of the heat dissipation box 2 A heat dissipation disk 5 with a plurality of through holes is provided for heat dissi...

Embodiment 2

[0040] like image 3 As shown, as shown in this embodiment and Embodiment 1, preferably, the connecting head 603 is a cover with a "convex" cross-sectional shape, and the end of the connecting head 603 close to the rotating rod 10 is provided with a compression spring A604, and the compression spring A604 It is placed in the inner hole of the rotating rod 10 to ensure that it can move according to the flapping assembly 13 and realize a certain fine-tuning. The end of the connecting head 603 away from the compression spring A604 is provided with two inner holes. The cleaning plate 601 and the connecting head 603 There are two hand-tightening bolts 602, and the screw connection between the hand-tightening bolts 602 and the inner hole is screwed to the cleaning plate 601 on the connection head 603. Through the setting of the hand-tightening bolts 602, the cleaning plate 601 can be moved Disassembly and installation facilitates the removal of the cleaning board 601 and facilitates...

Embodiment 3

[0042] like image 3 As shown, as shown in this embodiment and Embodiment 1, preferably, the rod body of the rotating rod 10 is also provided with fan blades 15 facing the heat dissipation plate 5 for heat exchange of the heat conducting plate to ensure the heat dissipation effect. On the one hand, the fan blades 15 The heat exchange of the heat conducting plate can be carried out, and on the other hand, when the beating assembly 13 shakes out the dust, the effect of blowing out the dust can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com