Motor driving device

A technology of motor drive and motor parameters, applied in emergency protection circuit devices, multiple motor speed/torque control, electrical components, etc., can solve the problems of space occupation, power line wiring, high cost, etc., and achieve fast positioning and functions Comprehensive, integrated controls for simple and efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0073] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

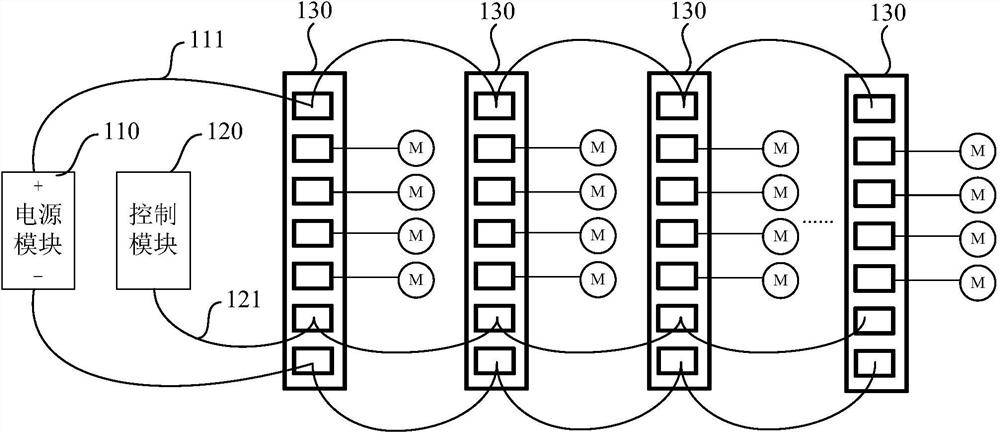

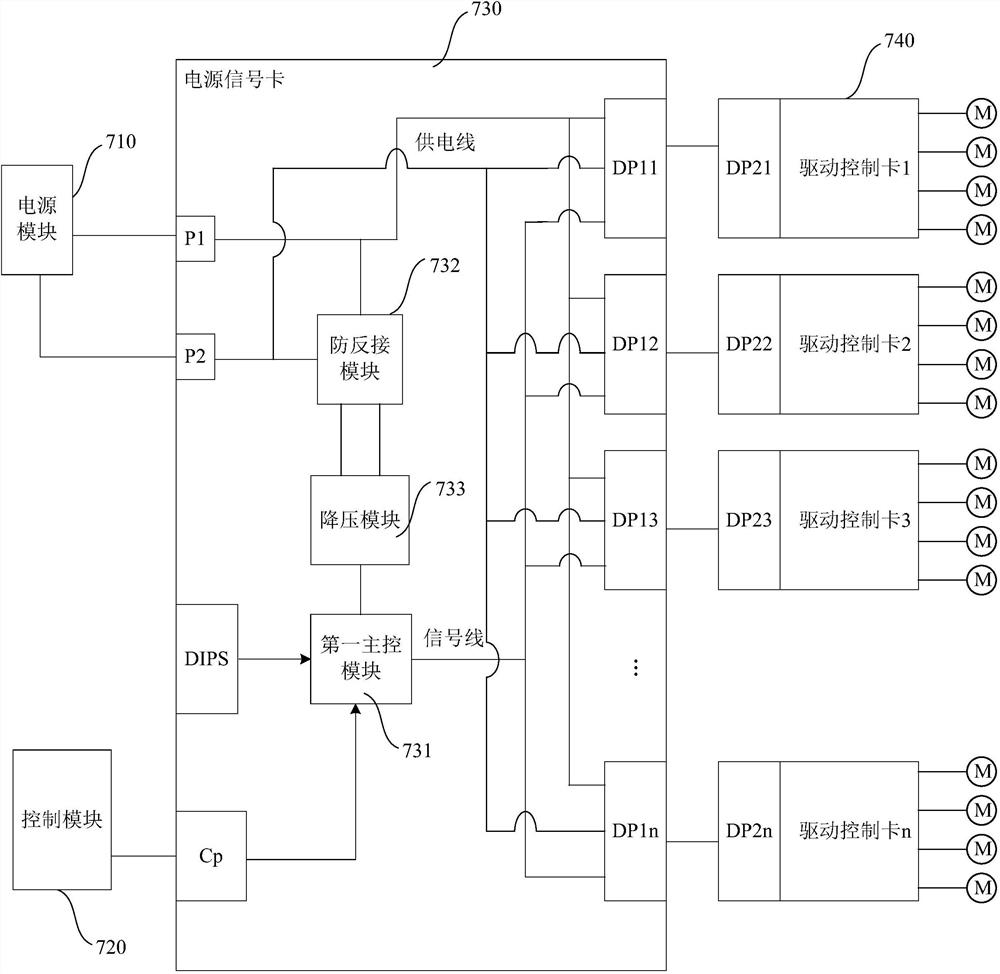

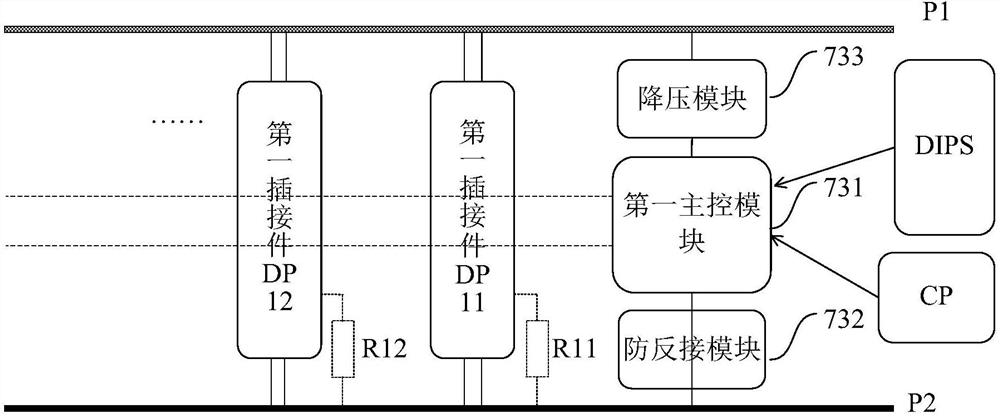

[0074] figure 2 It shows a circuit block diagram of a motor driving device provided according to an embodiment of the present invention; image 3 A schematic circuit diagram of a power supply card in a motor drive device according to an embodiment of the present invention is shown. The motor drive device includes a power module 710 , a control module 720 , a power card 730 and a drive control card 740 . Wherein, the power supply card 730 and the drive control card 740 are located in a packagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com