Conveying equipment for building top surface greening

A technology for conveying equipment and buildings, which is applied in the field of conveying equipment for greening the top of buildings, can solve the problems of time-consuming, labor-intensive, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

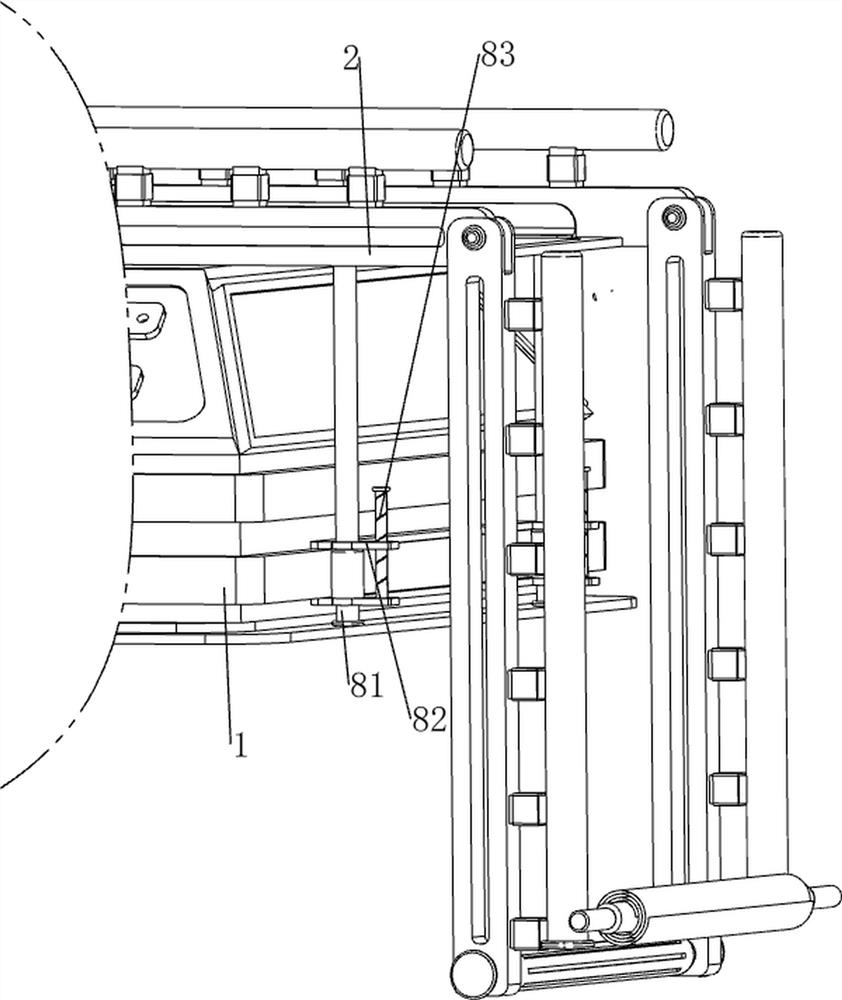

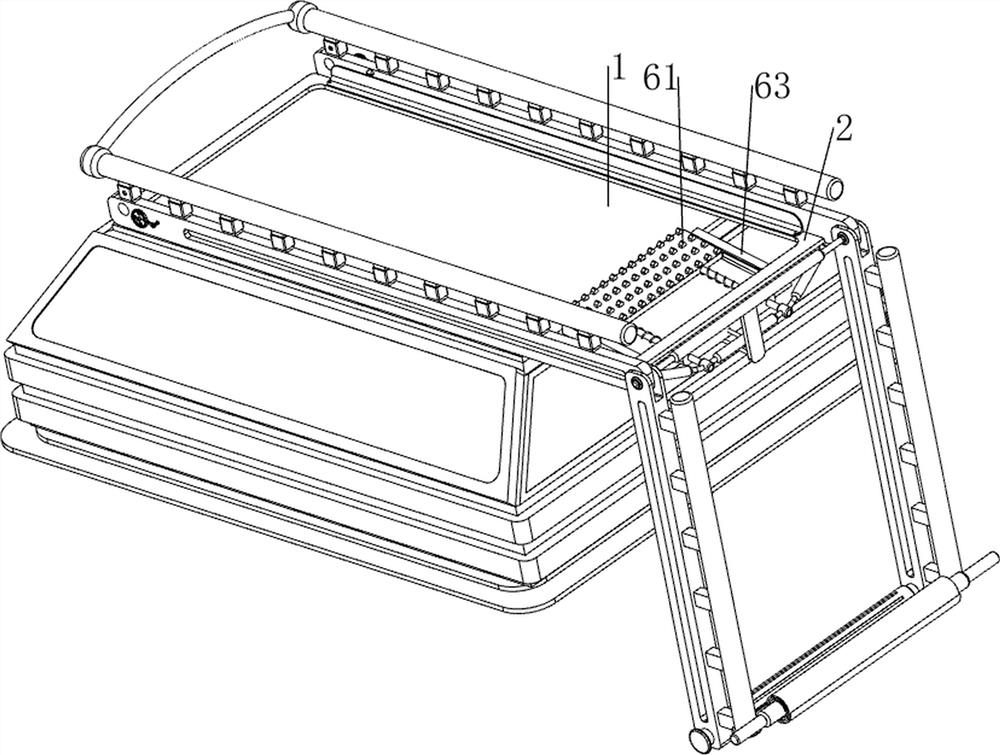

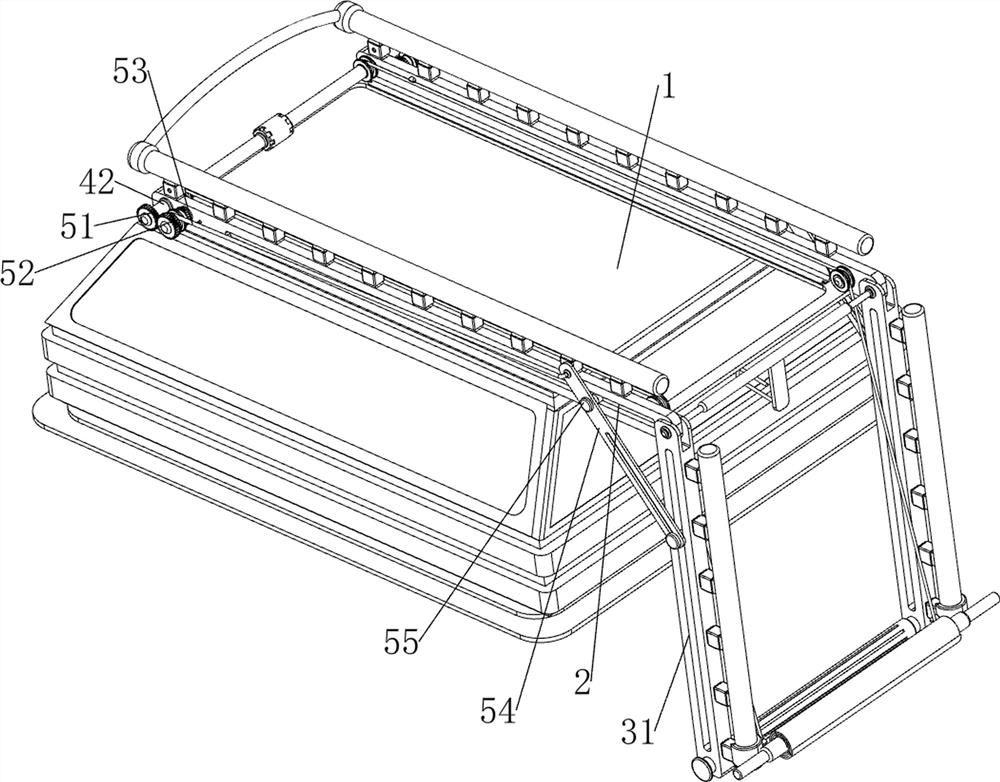

[0034] A conveying device for greening on the top of a building, such as Figure 1-10 As shown, it includes a bottom plate 2, a first slide rail 3, a second slide rail 31, a sliding sleeve 32, a roller 33, a conveying mechanism 4, a rotating mechanism 5 and a blanking mechanism 6, and the bottom plate 2 is installed on the building 1 by bolts. The position of the top, the first slide rail 3 is welded on the front and back sides of the top of the bottom plate 2, the second slide rail 31 is rotatably connected between the right side of the bottom plate 2, and the right part of the second slide rail 31 is slidably connected with a sliding sleeve 32, Sliding sleeve 32 can slide on the second slide rail 31, and between two sliding sleeves 32, roller 33 is connected in a rotatable manner, and roller 33 can rotate, and the lawn can be rolled up by roller 33. A conveying mechanism 4 is provided, a rotating mechanism 5 is provided on the bottom plate 2, and the rotating mechanism 5 can...

Embodiment 2

[0040] On the basis of Example 1, such as figure 1 , figure 2 , Figure 11 and Figure 12 As shown, it also includes a clamping mechanism 7, which can clamp and limit the lawn. The clamping mechanism 7 includes a clamping plate 71, a fourth rotating shaft 72, a torsion spring 73 and a third spring 74. The fourth rotating shaft 72 is rotatably connected on the cover 32, and the fourth rotating shaft 72 is slidably connected with a clamping plate 71. The clamping plate 71 can clamp and limit the lawn. The upper and lower sides of the fourth rotating shaft 72 and the sliding A torsion spring 73 is provided between the sleeves 32 , and a third spring 74 is provided between the upper and lower sides of the left part of the clamping plate 71 and the sliding sleeve 32 .

[0041] When people roll the lawn around the roller 33, they can turn the clamping plate 71 and the fourth rotating shaft 72 outwards, so that the torsion spring 73 is twisted, and then start to roll the lawn. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com