A straw slice cleaning device for straw painting

A wheat straw slicing and cleaning device technology, applied in special decorative structures, decorative arts, mechanical equipment and other directions, can solve problems such as scraping, cleaning and other processes that cannot be carried out, speed up the production efficiency of handicrafts, and difficulty in inheritance and continuation. Preparation time, vibration mitigation, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

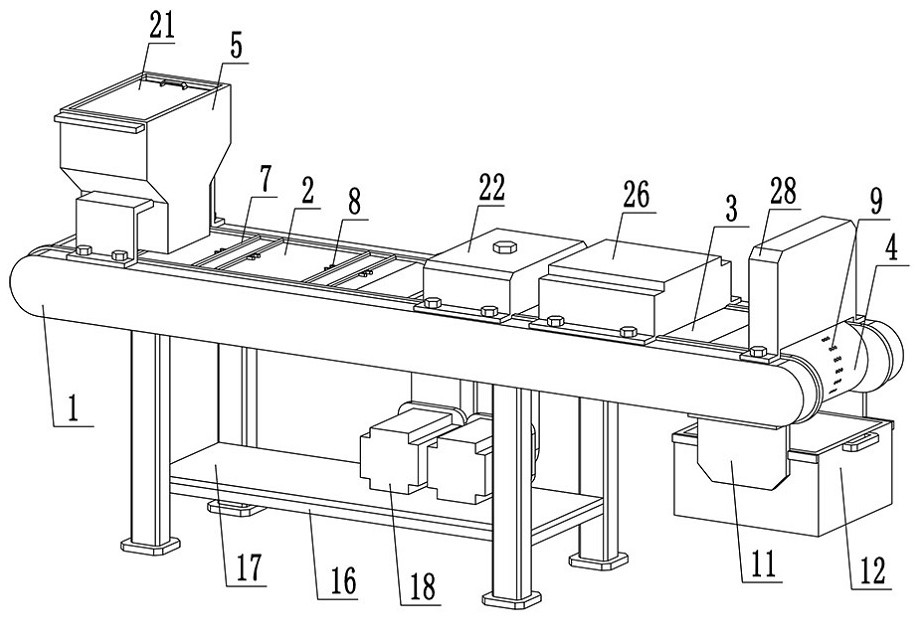

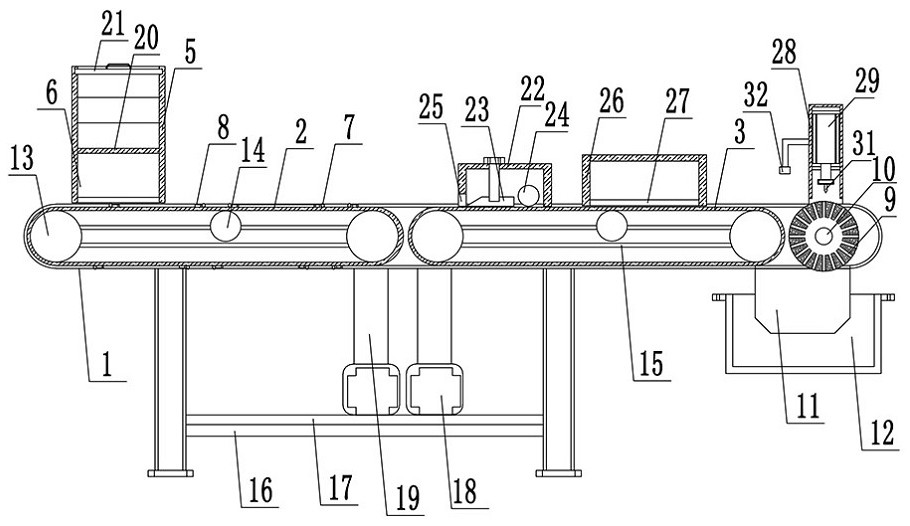

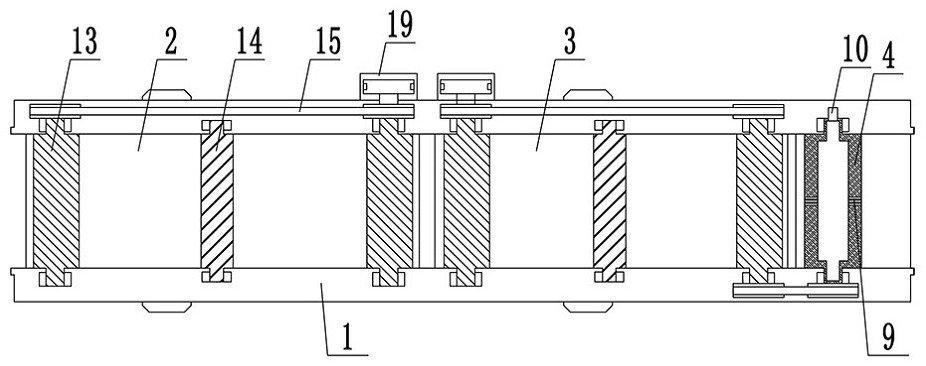

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0026] Such as Figure 1~Figure 7 As shown, a straw slice cleaning device for wheat straw painting includes a frame 1, a partition conveyor belt 2, a flat conveyor belt 3, and a vacuum roller 4. The partition conveyor belt 2, the flat conveyor belt 3 and the vacuum roller The cylinders 4 are sequentially spaced and distributed on the frame 1, and are rotatably connected to the frame 1. The centerline of the partition conveyor belt 2 and the flat conveyor belt 3 are the same. They are located on the frame 1 and are provided at the corresponding position of the partition conveyor belt 2. Feeding box 5, the cross-section of the feeding box 5 is a funnel shape, the feeding box 5 is provided with a discharging trough 6, the discharging trough 6 is located in the middle of the feeding box 5, the discharging trough 6 is rectangular, The width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com