Extrusion device for aluminum pipe machining

A technology of extrusion device and aluminum tube, which is applied in the field of extrusion, can solve the problems of high noise of extrusion machines, easily damaged machines, and difficult to move, and achieve the effects of reducing noise, operating safely, and protecting machine accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

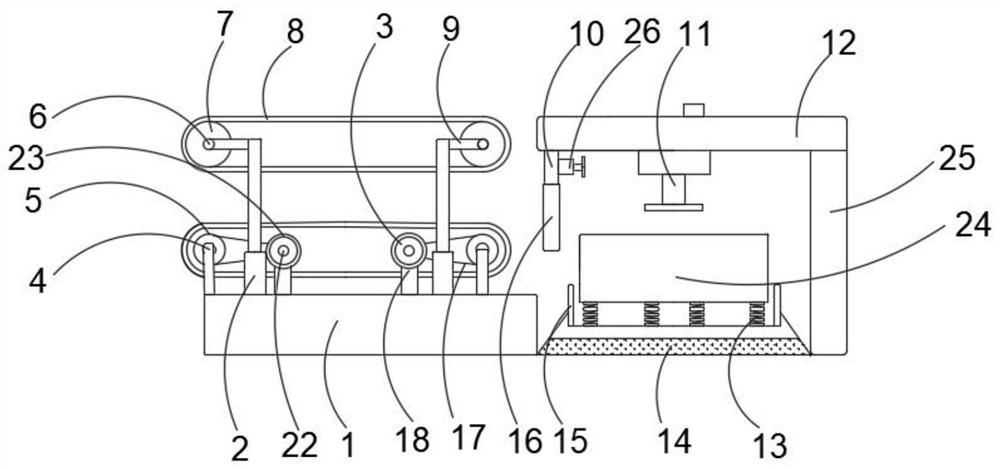

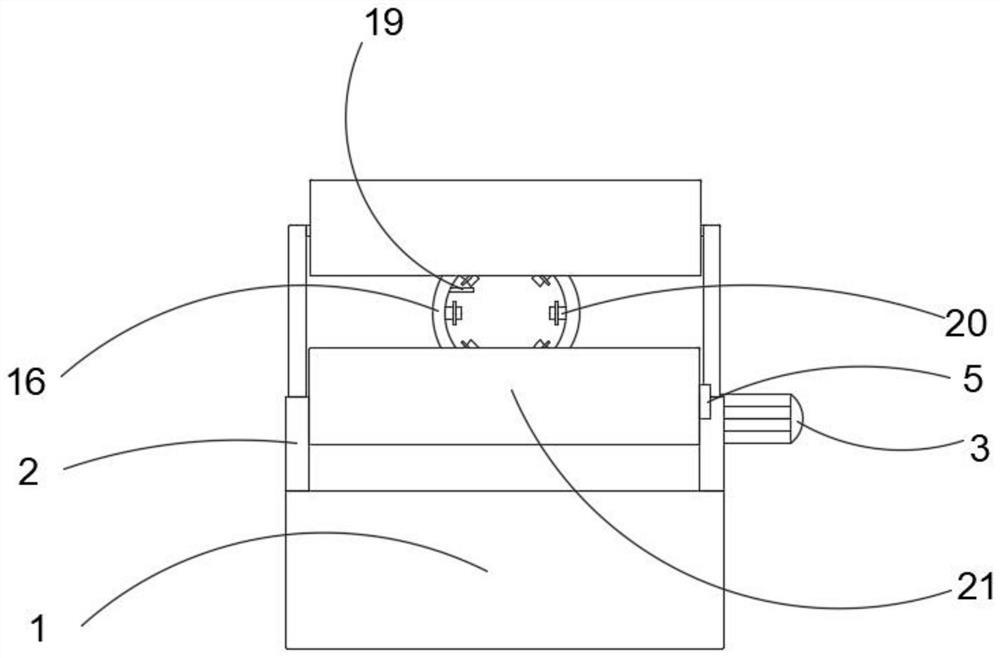

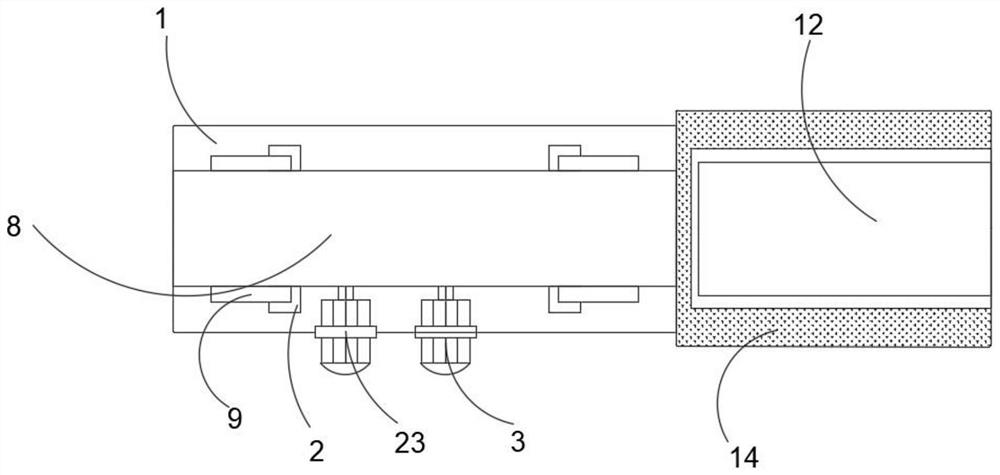

[0023] In embodiment 1, such as Figure 1-3 As shown, the present invention provides an extrusion device for aluminum tube processing, which includes a box body 1 and a rubber layer 14. The top of the box body 1 near the four corners is fixedly connected with the first electric telescopic rod 2, and the four first The top of the electric telescopic rod 2 is fixedly connected with the second fixed block 9, the two sides of the top of the front surface of the box body 1 are fixedly connected with the first fixed block 4, and the inner surfaces of the two first fixed blocks 4 are all slidably connected with the second fixed block 9. A belt pulley 5, the outer surfaces of the two first belt pulleys 5 are all slidingly sleeved with a belt strip 17, and the other ends of the inner surfaces of the two belt belt strips 17 are movably embedded with a second shaft center wheel 22, and the two first belt pulleys 5 The outer surface of the outer surface is fixedly connected with a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com