High-precision filter element for adsorption desulfurization device, filter element assembly and preparation method

An adsorption desulfurization, high-precision technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of inability to ensure long-term stable operation of gasoline adsorption desulfurization units, poor backflushing effect, and low filtration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

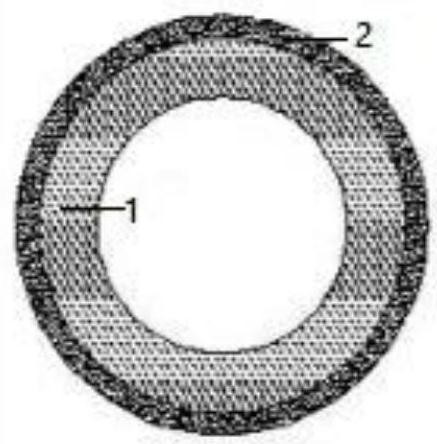

[0047] This embodiment provides a gradient composite sintered metal filter element (such as figure 1 As shown), the filter element size of the gradient composite sintered metal filter element is φ60×2980mm (mm), including four single-section gradient composite sintered metal filter elements, the effective filtration length of the single-section gradient composite sintered metal filter element is 690mm, and the single-section gradient composite sintered The metal filter element includes a tubular matrix powder sintered body 1 and a filter membrane coating 2, and the filter membrane coating 2 is sprayed on the outer wall surface of the tubular matrix powder sintered body 1; between the bottom end and the top end of the adjacent single-section gradient composite sintered metal filter element The reinforcement ring is welded, and the reinforcement ring is made of dense stainless steel connecting ring, which makes the gradient composite sintered metal filter element have higher over...

Embodiment 2

[0069] This embodiment provides a gradient composite sintered metal filter element (such as figure 1 Shown), including tubular matrix powder sintered body 1 and filter membrane coating 2, the filter element size of the gradient composite sintered metal filter element is φ60×648mm.

[0070] The preparation method of the gradient composite sintered metal filter element of the present embodiment comprises the following steps:

[0071] 1) Powder raw material preparation:

[0072] The base powder is water-atomized stainless steel powder with irregular shape of -80+160 mesh. The irregular shape is dendritic or teardrop-shaped. The coating powder is similar to spherical stainless steel powder of -400 mesh. The specific type of stainless steel powder is not specifically limited. Those skilled in the art can select according to the use requirements. The matrix powder in this embodiment is preferably stainless steel 304 powder.

[0073] 2) Isostatic pressing

[0074] The matrix powde...

Embodiment 3

[0090] This embodiment provides a gradient composite sintered metal filter element (such as figure 1 As shown), the filter element size of the gradient composite sintered metal filter element is φ60×3109mm, including four single-section gradient composite sintered metal filter elements, the effective filtration length of the single-section gradient composite sintered metal filter element is 725mm, and the single-section gradient composite sintered metal filter element includes The tubular matrix powder sintered body 1 and the filter membrane coating 2, the filter membrane coating 2 is sprayed on the outer wall of the tubular matrix powder sintered body 1; the bottom end and the top end of the adjacent single-section gradient composite sintered metal filter element are welded with a reinforcing ring , The reinforcing ring is a dense stainless steel connecting ring, which makes the gradient composite sintered metal filter element have higher overall strength and high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com