Dense medium mineral separation equipment for mineral separation of non-ferrous metal ores

A technology of mineral processing equipment and non-ferrous metals, which is applied in the field of dense medium mineral processing equipment, can solve the problems of increasing manpower, time-consuming, troublesome mineral extraction, etc., and achieve the effect of reducing workload, convenient use, and saving operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

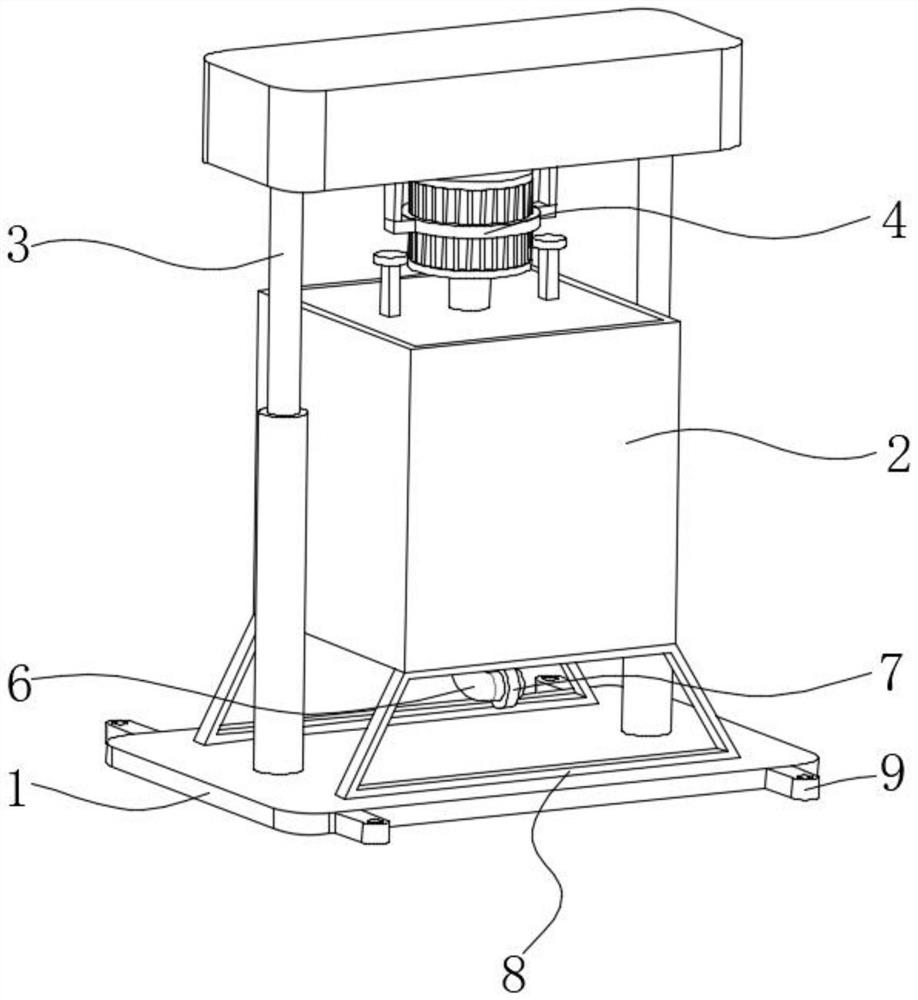

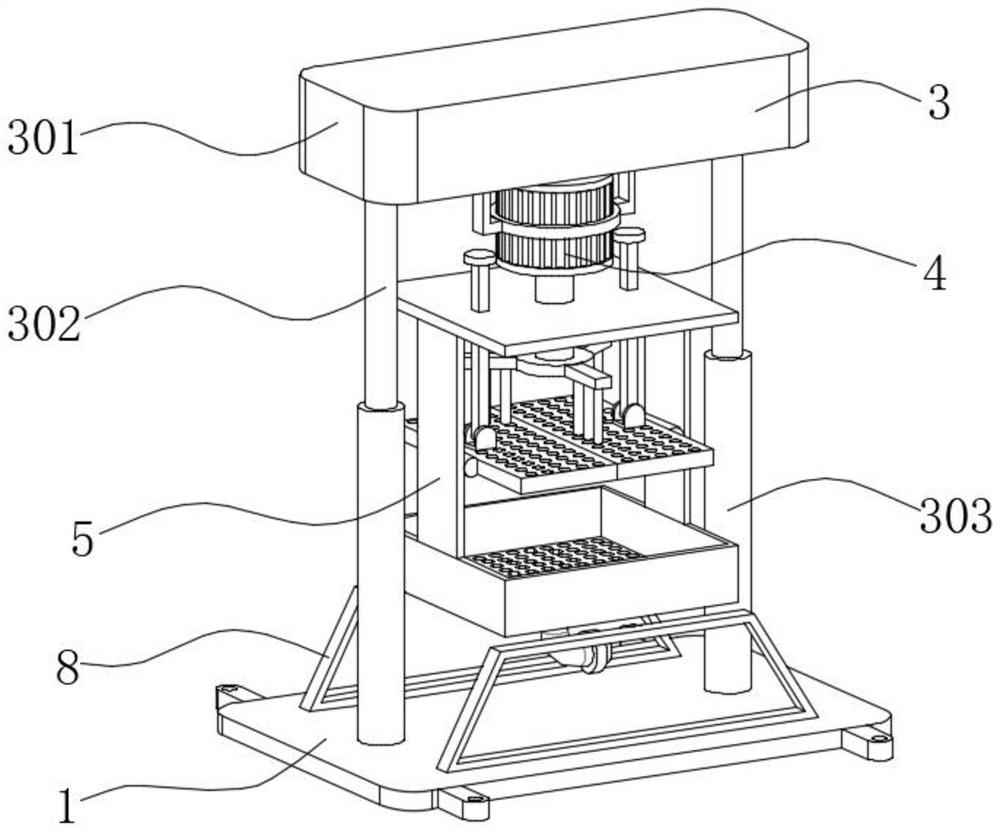

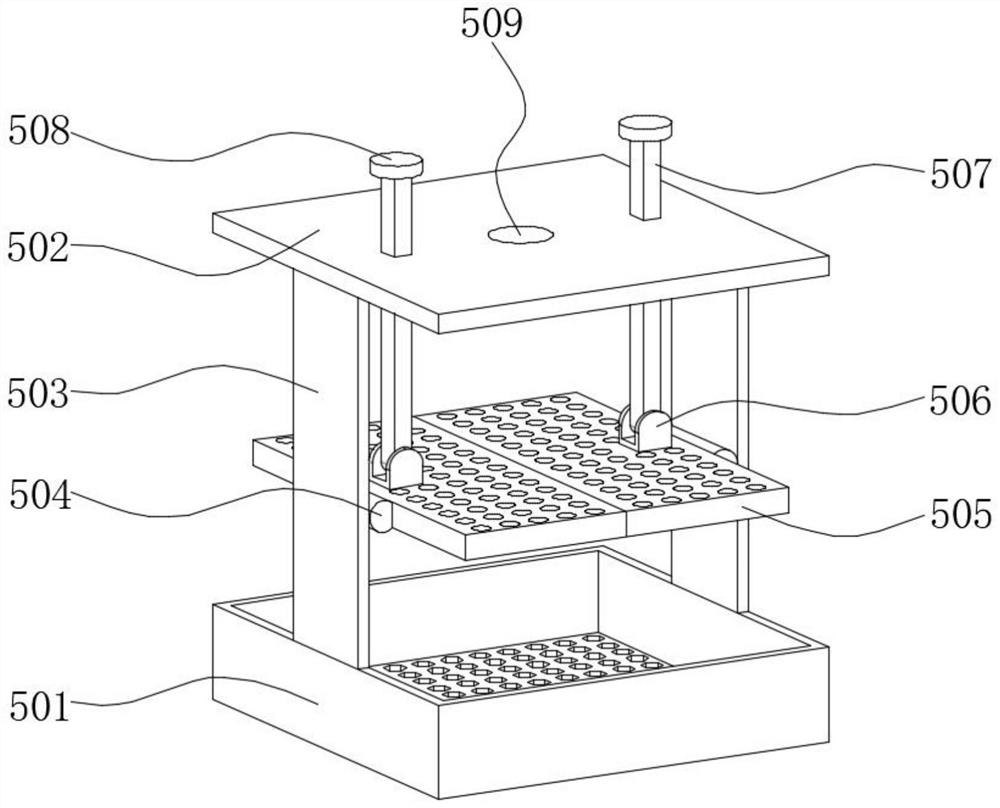

[0022] This embodiment provides a dense medium mineral processing equipment for mineral processing of non-ferrous metal ores. The device can be set through the cooperation between the lifting mechanism 3, the stirring mechanism 4 and the ore extraction mechanism 5, and can be used for one-time operation after mineral separation. Minerals can be taken out efficiently, it is no longer necessary for operators to use net bags to take out low-density minerals and then take out high-density minerals, which effectively reduces the workload of the staff, saves the working time of the staff, and is convenient for people use.

[0023] see Figure 1 ~ Figure 4 , a heavy medium mineral processing equipment for non-ferrous meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com