Manufacturing method and application of insulating layer for electrostatic ultrasonic transducer

A technology of an ultrasonic transducer and a manufacturing method, which are applied in the field of ultrasonic transducers, can solve the problems of difficult display panel integrated design, etc., and achieve the effects of high breakdown voltage, high transparency, and expanding application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

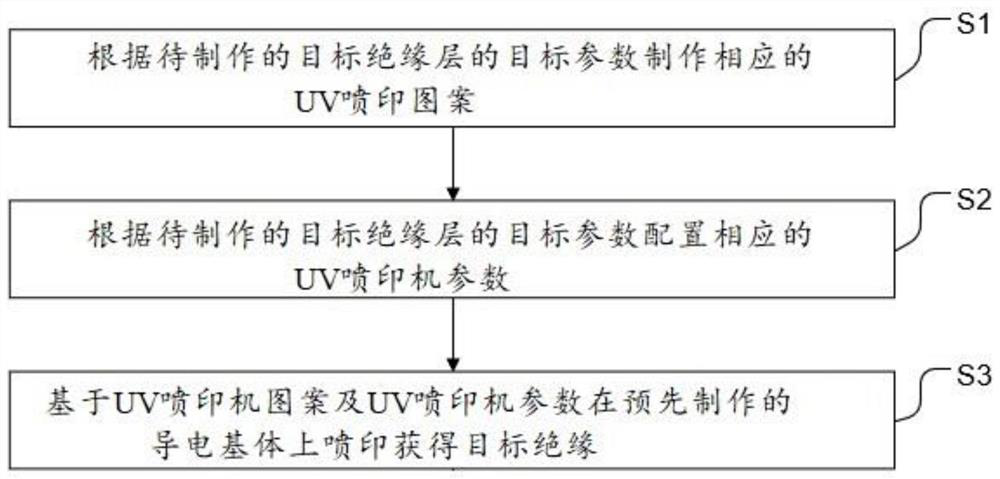

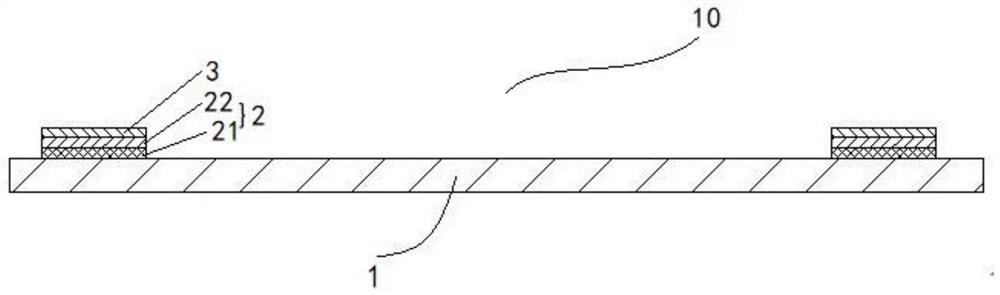

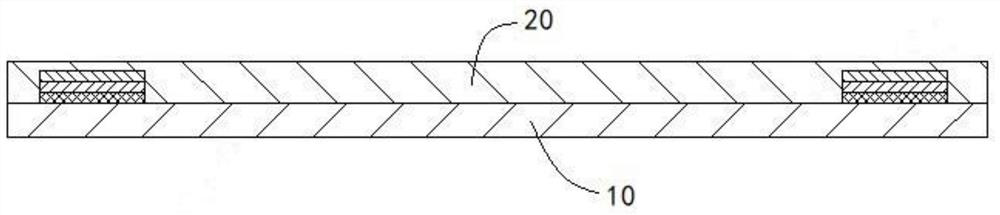

[0052] Such as figure 1 As shown, this embodiment provides a method for fabricating an insulating layer for an electrostatic ultrasonic transducer, which is used to fabricate a target insulating layer on a conductive substrate that meets target parameters, and the target parameters include transparency and thickness. The production method includes:

[0053] S1. Make a corresponding UV printing pattern according to the target parameters of the target insulating layer to be produced. Wherein, the target parameters include target thickness and / or target transparency of the target insulating layer.

[0054] Specifically, step S1 includes:

[0055] S11. Import the AI original image of the target insulation layer into the drawing software.

[0056] It should be noted that the UV inkjet printer adopts ultraviolet curing technology, using UV ink (UV refers to ultraviolet light) as the raw material for printing, and the printed pattern can be printed and dried immediately under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com